Category:Bench Grinders

From Artisans Asylum Wiki

| Bench grinders | |

|---|---|

| General Info | |

| Make | Varied |

| Model | Varied |

| Serial | Unknown |

| Specs | n/a |

| Manual | |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | n/a |

| Training | Tool classes |

| Testing | Tool testing, or come to the shop on Tool Testing Night |

| Restrictions | red |

Metal Shop

Materials

Use for:

- Deburring, beveling, chamfering

- Mild steel

- Stainless steel

- Hardened steel

Do not use for:

- Removing large amounts of material

- Very small parts

- Soft metals, especially aluminum (see below)

- Also do not grind copper, brass, bronze, or titanium

- TIG tungstens, except the grinder labeled "tungsten only" (this is to prevent cross-contamination)

Why can't I grind aluminum?

| Do NOT grind Aluminum on our bench grinders! | |

|---|---|

Aluminum has a low melting point. Grinding aluminum on a bench grinder designed for steel gums up the stone, reducing its grinding capacity, and the heat of grinding melts the aluminum, sending it deeper into the stone. Once contaminated with aluminum, the stone needs to be fully dressed to remove all of the aluminum before it can be used with steel.

ALSO: Aluminum + Rust + Heat = A Thermite Explosion.

| Please, do not booby trap our grinding wheels with potentially explosive materials! | |

|---|---|

Safety Hazards

| Eye protection required! | ||

|---|---|---|

- Spark spray

- Breaking wheels/flying wires on wire wheels

- Drawn-in injuries - do not wear loose clothing, gloves, or rings

- Cuts / scrapes from sharp cut edges of work

- Fire hazard from sparks

- Burns from hot work

Operation Notes

- Do not grind work that is smaller than the gap between the rest and the wheel. Your workpiece can be drawn in, damaging your hands as well as the wheel.

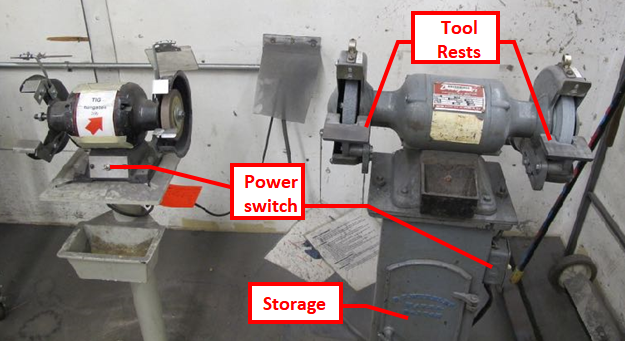

- Adjust the rests as needed to keep a close fit against the grinding wheel.

- The wheels are designed for grinding flat on the outside edge. Do not grind on the side of the wheels. Do not grind on the wheel’s corner.

- Do not use a damaged wheel. Damaged wheels can break while in operation, sending debris flying.

- Stand to one side of the grinder until the wheel reaches operating speed. When possible, remain outside of the machine’s “danger zone,” where loose debris and particles shoot out in line with the belt’s rotation.

- Bring work into contact with the grinding wheel slowly and smoothly, without bumping.

- Move the work back and forth across the face of the wheel to prevent grooves in the wheel.

- Do not remove safety shields from grinders. They are there to protect you.

- Grind NOTHING BUT TUNGSTEN on tungsten wheel. A wire wheel for general use is usually installed on the tungsten grinder.

- Wheels will keep spinning after shutdown, until they slowly come to a stop.

- Dressing tools and spare wheels are stored in the supply cabinet or in grinder’s pedestal.