Category:MIG Welders: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

[[Category:Tools]][[Category:Welders]] | [[Category:Tools]][[Category:Welders]] [[Category:Metal Shop]] | ||

{{Warning|text='''Extra precaution required for welders.''' Training / Tool Testing is essential. See [https://www.dropbox.com/scl/fi/vxp99od0h481geq45avrp/Welding-Safety.pdf?rlkey=gv6csj0p7o5n3c341w58v78vl&dl=0 Welding Safety] doc.}} | {{Warning|text='''Extra precaution required for welders.''' Training / Tool Testing is essential. See [https://www.dropbox.com/scl/fi/vxp99od0h481geq45avrp/Welding-Safety.pdf?rlkey=gv6csj0p7o5n3c341w58v78vl&dl=0 Welding Safety] doc.}} | ||

Revision as of 19:54, 8 February 2024

| Extra precaution required for welders. Training / Tool Testing is essential. See Welding Safety doc. | |

|---|---|

| Eye protection required! | ||

|---|---|---|

| MIG Welders | |

|---|---|

| General Info | |

| Make | Varied |

| Model | Varied |

| Serial | Unknown |

| Specs | n/a |

| Manual | |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | n/a |

| Training | [https://www.artisansasylum.com/class-

catalog Tool classes] |

| Testing | [https://www.artisansasylum.com/tool-testing Tool

testing], or come to the shop on Tool Testing Night |

| Restrictions | red |

There are two models of MIG welders at Artisans Asylum:

Manuals are available in the Equipment Manuals Google Drive

Link to: Millermatic 212 Manual

Link to: Millermatic 252 Manual

Materials

Use for:

- Mild Steel ONLY

Do not use for:

- Galvanized

- Plated

- Painted

- Oiled

- Rusted

- Powder-coated

- Greasy

- Nasty

- Ugly

- Bad

Safety Hazards

| |

|---|---|

1. UV damage to eyes. Welding Helmet with shade 12 protection or darker is required.

2. UV burns on exposed skin. The rays from the arc can cause severe radiation burn (worse than sunburn.) Cover exposed skin.

3. Burns from flame, sparks, hot workpieces. Wear welding gloves, cotton clothing (no synthetics) and closed toe shoes.

4. Poisoning from breathing gases produced by welding. Use ventilation. Do not stick head in fumes. Respirator recommended.

5. Keep workplace clear of flammable materials including grease, oil, solvents, paper.

6. Electrocution if welder is mishandled. Do not weld near puddles of water on floor or work area.

* Various safety links to keep you awake at night:

ANSI - General Safety in Welding and Cutting

Operation Notes

- Solvent based metal cleaning should be done with Simple Green or other low-intensity cleaners.

- Abrasive cleaning methods are also appropriate.

- No brake cleaner. Brake cleaner contains chlorinated hydrocarbons that creates phosgene ("Nerve gas" from WWI) when combined with UV light. Ventilation will not prevent poisoning.

MIG Welders Available:

- Millermatic 212 Auto Set - welds material from 22 gauge to 3/8 in (9/5mm) thick.

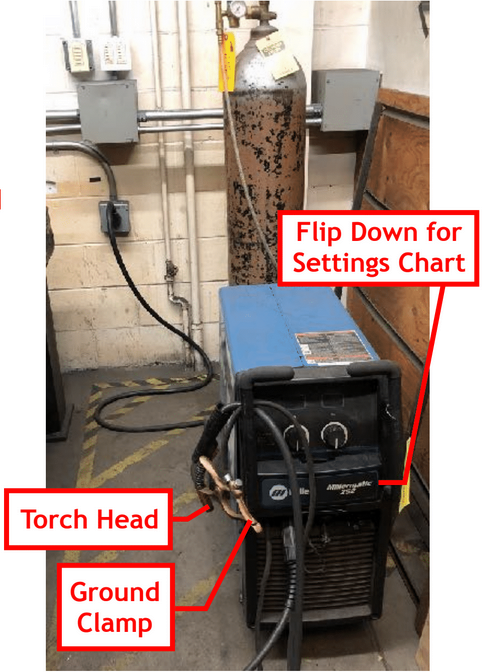

- Millermatic 252- welds material from 22 gauge to 1/2 in. thick.

The shop supplies 025, .030, and .035 inch copper coated steel filler wire.

- The MIG welders in the shop use a gas mixture of 75% Argon and 25% CO2. Purge lines after use.

- To reduce spatter build-up, lightly coat Torch Head with Nozzle Anti-Spatter Gel. (Found in welding bays.)

| |

|---|---|

| Flip-Down Chart on the Millermatic 212 |

Set-up Procedure

1. Safety First

- Turn on welding bay ventilation.

- Remove flammable materials and water from welding area.

- Protect bystanders from the arc-flash, If you can’t depend on the protective vinyl

flaps on the welding bays, use welding screens

2. Attach the ground clamp to bare metal on the work table.

If workpiece is too large for the work table, clamp the workpiece.

3. Check to see if the welder has been shut down properly.

- Is the power shut off?

- Is the gas shut off at the cylinder valve?

- Have the lines been bled (is the working pressure at zero)?

4. Plug the machine in and turn it on.

5. Turn the gas on. If needed, adjust the pressure.

- SLOWLY crack the tank valve counterclockwise. Watch the regulator needle jump, and check that the needle has stopped moving before opening the valve (about half a turn).

This procedure lessens the impact of the initial jump in pressure on the regulator, reducing wear and tear.

- Hold the torch away from the workbench (more than 12 inches) and pull the torch trigger to start the gas cycle.

- Check the regulator dial to make sure the working gas pressure matches the recommendation listed on the shop tag attached to the regulator. Adjust if needed.

- Note: An inaccurate working pressure reading may occur if the welder has been shut down improperly by the previous user. Press the trigger on the Torch Head to lower the line pressure and reset the gauge.

6. Set the machine's voltage and wire speed.

- Take note of the wire size (written on the spool inside the machine) and the thickness of the workpiece.

- Start with the settings recommended on the flip down chart located on the front of the machine. Adjust the settings further as needed.

7. When welding, avoid tight loops or extra loops in the torch cord.

Extra looping will stress the feed mechanisms and may slow down the wire speed.

8. Dross may build up on the gas nozzle and/or contact tip while welding.

Clean as necessary using MIG pliers. Spare torch parts, including replacement contact tips, are kept in the Metal Shop’s supply cabinet.

Shut-Down Procedure

1. Shut off the gas at the source. Turn the cylinder valve clockwise.

2. Bleed the lines.

- Turn the wire speed down as far as it will go.

- Pull the torch trigger and wait for the regulator gauge to read zero.

3. Flip the machine's power switch to "off."

4. Turn the ventilation off if no one else is using the bays.

5. Loosely coil the torch cord and store on the machine.

6. Put all tools away and clean the work area.

Videos

Havoc caused by a broken cylinder valve

Mythbusters episode on gas cylinder rocketry

Welding Safety

Safety-wise, make sure your gloves (and, for that matter, all your skin and clothing) remain dry. This is a much bigger factor than glove leather thickness in mitigating electrical shock hazard.

(Shock hazard is less of a concern with MIG than with TIG or stick.)

Basics

- ALWAYS wear a proper face shield.

- ALWAYS wear close-toed shoes.

- ALWAYS wear a long-sleeved, non-flammable shirt.

- ALWAYS wear proper welding gloves.

- ALWAYS wear ear protection (earplugs or muffs) to prevent sparks from entering your ear canal. An eardrum punctured by a spark will instantly cauterize and never heal.

- NEVER weld on or near anything that's been cleaned with a chlorinated hydrocarbon like brake-cleaner. When combined with UV light, chlorinated hydrocarbons can create phosgene gas, which can cause serious injury or death. Ventilation will not prevent poisoning.

- If you burn yourself, immediately douse with cold water: seconds count!

Fire

Make sure the weld area is free from all flammable materials such as flammable liquids, paper, etc.

Do not wear clothing or gloves that have been exposed to flammable liquids.

Electrocution

Before turning on a welding machine, make sure there are no puddles of water on the floor around the weld bench or the machine. Make sure the weld machine is dry, including the main box, the torch, the pedal, and the plug.

There is little risk of fatal electrocution from a properly working TIG weld machine. When the user presses on the pedal to initiate the arc, a high-frequency low amplitude arc will emit from the tip of the weld torch. Once the machine detects the grounded metal piece that is to be welded, the arc will switch over to a high-amplitude DC current. Even if the operator deliberately points it toward their body, the shock will be mild, since the machine will not switch over to the high amplitude current.

Burns

Welded metal will remain hot for several minutes after it is welded. In most cases the heat is localized near the weld itself.

In the case of more conductive materials, such as copper and aluminum, the heat may be more distributed throughout the material.

In the case of TIG welding, sparks and spatter are non-existent, unless rusty or dirty metal is used. MIG welding steel will create sparks, so earplugs and full coverage safety glasses should be worn to prevent burns to sensitive tissue.

Gloves must be worn when welding and handling recently welded material. White cotton welding gloves may be used for light TIG welding, as long as they are free of holes. For heavier welding, deerskin or heavy duty welding gloves should be used.

UV Burns

The light emitted from a weld arc is brighter than that of the sun. Do not look at the arc without wearing a full-faced welding mask with a shade 10 or darker filter plate.

Always make sure the weld curtains are in place between the welder(s) and other people in the shop.

Be sure to cover any exposed skin, including cuff and collar areas, while welding or observing inside the weld area.

The rays from the arc can cause a UV burn much worse than a sunburn.

Observers may use a cardboard mask with a shade 10 filter plate.

Compressed Gas Cylinders

Argon and CO2 are inert, nontoxic gases normally present in the atmosphere. However, if allowed to fill an enclosed area these gases can fully displace breathable air, causing asphyxiation and death.

At the Asylum, the greater potential danger is the valve being knocked off the cylinder, turning it into a rocket powerful enough to severely injury or kill people and damage equipment and the building itself.

The following guidelines must be followed at all times:

Storing

- Cylinders must ALWAYS remain upright and NEVER be placed horizontally.

- Cylinders must be secured with a non-combustible material (metal) to an immovable object to prevented them from falling.

Moving

- Cylinders must be securely capped.

Pages in category "MIG Welders"

The following 2 pages are in this category, out of 2 total.