Category:Milling Machines

From Artisans Asylum Wiki

| Vertical Milling Machines | |

|---|---|

| General Info | |

| Make | various |

| Model | |

| Serial | |

| Specs | |

| Manual | |

| Asylum Info | |

| Location | Machine Shop |

| Rubric | |

| Training | |

| Testing | |

| Restrictions | red |

Description

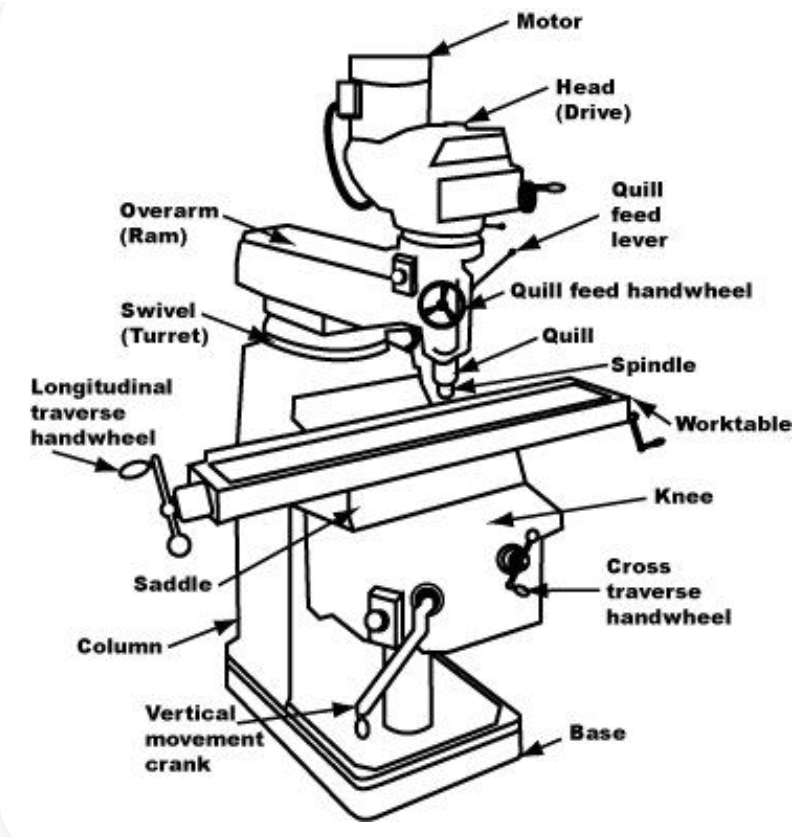

On a milling machine, parts are created by removing material from a solid block (or workpiece) using a variety of spinning cutting tools.

A 3-axis vertical milling machine has a variable-speed vertical spindle and a heavy table that translates underneath it. A metal workpiece is clamped to the table and a cutting tool is held in the spindle. Cutting is done by moving the workpiece against the spinning tool, or by lowering the spinning tool into the workpiece.

A CNC milling machine operates by computer control. Motors are attached to the movement mechanics allowing the computer to make precision-machined parts automatically.

| Use For | Do Not Use For |

|---|---|

|

|

Safety Notes

Personal

| Eye protection required! | ||

|---|---|---|

- Wear safety goggles. Eyeglasses are NOT safety goggles.

- Beware of flying chips. They are HOT and SHARP.

- Do not wear loose clothing or jewelry when operating the machine. Long hair must be tied back or covered.

- Do not wear gloves. Gloves can be drawn into a cut by the spinning tool.

- Do not remove chips from the cutting area with bare hands. Use a chip brush or a shop-vac.

- Always keep a secure, stable stance. Avoid over-reaching. Clean up oil spills immediately and avoid slipping. Keep the work area clear of trip hazards.

Machine

Pages in category "Milling Machines"

The following 6 pages are in this category, out of 6 total.