Category:MIG Welders and Category:TIG Welders: Difference between pages

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

[[Category:Tools]][[Category:Welders]] | [[Category:Tools]][[Category:Welders]][[Category:Metal Shop]] | ||

{{Warning|text='''Extra precaution required for welders.''' Training / Tool Testing is essential. See [https://www.dropbox.com/scl/fi/vxp99od0h481geq45avrp/Welding-Safety.pdf?rlkey=gv6csj0p7o5n3c341w58v78vl&dl=0 Welding Safety] doc.}} | {{Warning|text='''Extra precaution required for welders.''' Training / Tool Testing is essential. See [https://www.dropbox.com/scl/fi/vxp99od0h481geq45avrp/Welding-Safety.pdf?rlkey=gv6csj0p7o5n3c341w58v78vl&dl=0 Welding Safety] doc.}} | ||

| Line 5: | Line 6: | ||

{{EyeWarning}} | {{EyeWarning}} | ||

{{ToolBox|tool_title= | {{ToolBox|tool_title=TIG Welders|image=metal_shop_TIG_welder_nolabels.png|caption=TIG welder in | ||

the Metal Shop ( | the Metal Shop (Everlast 250 EX)|location=Metal Shop|training=[https://www.artisansasylum.com/class- | ||

catalog Tool classes]|testing=[https://www.artisansasylum.com/tool-testing Tool | catalog Tool classes]|testing=[https://www.artisansasylum.com/tool-testing Tool | ||

testing], or [[:Category:Metal Shop#Tool Testing Night|come to the shop on Tool | testing], or [[:Category:Metal Shop#Tool Testing Night|come to the shop on Tool | ||

Testing Night]]|restrictions=red|make= | Testing Night]]|restrictions=red|make=Various|model=Various|serial=Unknown| | ||

manufacturer_specs=n/a|manual=[[Category:MIG_Welders#Operation Notes]]|rubric=n/a| | manufacturer_specs=n/a|manual=[[Category:MIG_Welders#Operation Notes]]|rubric=n/a| | ||

tool_categories=}} | tool_categories=}} | ||

''' | '''Tools in this category are:''' | ||

[https://wiki.artisansasylum.com/wiki/Everlast_Power_TIG_200DV_TIG_Welder Everlast_Power_TIG_200DV_TIG_Welder "Artemis"] | |||

[https://wiki.artisansasylum.com/wiki/Everlast_Power_TIG_250EX_TIG_Welder Everlast_Power_TIG_250EX_TIG_Welder "Athena"] | |||

[https://wiki.artisansasylum.com/wiki/ | [https://wiki.artisansasylum.com/wiki/Square_Wave_TIG_175_Pro_TIG_Welder Lincoln Electric Square Wave TIG 175 Pro] | ||

[https://wiki.artisansasylum.com/wiki/ | [https://wiki.artisansasylum.com/wiki/Synchrowave_200_TIG_Welder Miller Syncrowave 200] | ||

'''Equipment Manuals are available for these tools:''' | |||

Link to: [https://drive.google.com/file/d/13Jkc7Ye9_a6WHaaFbaToUt9ko2UGP0Lv/view?usp=drive_link TIG 200DV Manual] | |||

Link to: | Link to: [https://drive.google.com/file/d/1xQA9Iqqm45rfG4BD2cN5b5ezIWicYxtQ/view?usp=drive_link 250EX Manual] | ||

Link to: | Link to: [https://drive.google.com/file/d/1FnM4Hc6KAvR8e_cYMpZThZ90LaucveyI/view?usp=drive_link Square Wave 175 Pro Manual] | ||

Link to: [https://drive.google.com/file/d/1xvyn7y0exuV-A-n6i5LjVQ48Nj77KT52/view?usp=drive_link Synchrowave 200 Manual] | |||

==Use for:== | |||

* Most metals: Steel, stainless, aluminum, titanium, etc. | |||

''' | * '''The shop provides consumables for mild steel''' (filler wire, 2% thoriated tungsten). Users provide consumables for other metals. | ||

* | * See corresponding manufacture manual for each welder’s stick welding capabilities. | ||

==Do Not Use for:== | |||

* Galvanized | * Galvanized, plated, painted, oiled, rusted, or powder coated metals. | ||

== Safety Hazards == | == Safety Hazards == | ||

| Line 56: | Line 55: | ||

|} | |} | ||

1. '''UV damage to eyes.''' Welding Helmet with shade | 1. '''UV damage to eyes.''' Welding Helmet with shade 10 protection or darker is required. Darker for heavier applications. | ||

2. '''UV burns on exposed skin.''' The rays from the arc can cause severe radiation burn (worse than sunburn.) Cover exposed skin. | 2. '''UV burns on exposed skin.''' The rays from the arc can cause severe radiation burn (worse than sunburn.) Cover exposed skin. | ||

| Line 62: | Line 61: | ||

3. '''Burns''' from flame, sparks, hot workpieces. Wear welding gloves, cotton clothing (no synthetics) and closed toe shoes. | 3. '''Burns''' from flame, sparks, hot workpieces. Wear welding gloves, cotton clothing (no synthetics) and closed toe shoes. | ||

4. '''Poisoning''' from breathing gases produced by welding. Use ventilation. Do not stick head in fumes. Respirator recommended. | 4. '''Poisoning''' from breathing gases produced by welding. Use ventilation. ''Do not stick head in fumes.'' Respirator recommended. | ||

5. Keep workplace '''clear of flammable materials''' including grease, oil, solvents, paper. | 5. Keep workplace '''clear of flammable materials''' including grease, oil, solvents, paper. | ||

6. '''Electrocution''' if welder is mishandled. Do not weld near puddles of water on floor or work area. | 6. '''Electrocution''' if welder is mishandled. Do not weld near puddles of water on floor or work area, especially when using AC output. | ||

'''Various safety links to keep you awake at night:''' | '''* Various safety links to keep you awake at night:''' | ||

[https://www.ccohs.ca/oshanswers/safety_haz/welding/fumes.html Welding Fumes] | [https://www.ccohs.ca/oshanswers/safety_haz/welding/fumes.html Welding Fumes] | ||

| Line 78: | Line 77: | ||

[https://drive.google.com/file/d/1WoYK1vVHJLuaoRHqeJEC6zsi2RgVmj4I/view?usp=drive_link ANSI - General Safety in Welding and Cutting] | [https://drive.google.com/file/d/1WoYK1vVHJLuaoRHqeJEC6zsi2RgVmj4I/view?usp=drive_link ANSI - General Safety in Welding and Cutting] | ||

== Operation Notes == | ==Operation Notes== | ||

* '''Solvent based metal cleaning should be done with Simple Green or other low-intensity cleaners.''' | |||

* '''No brake cleaner.''' Brake cleaner contains chlorinated hydrocarbons that create '''phosgene gas''' when combined with UV light. ''Ventilation will not prevent poisoning.'' | |||

* Abrasive cleaning methods are also appropriate. | |||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | |||

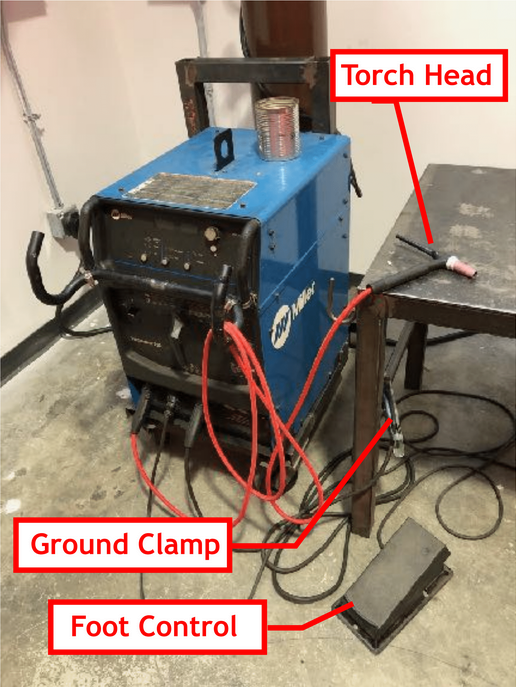

! colspan="2" class="infobox-image" | [[File:Metal_shop_TIG_welder_labels.png|300px|TIG welder]] | |||

|- | |||

| colspan="2" | TIG welder in the Metal Shop | |||

|- | |||

|} | |||

* The Shop supplies TIG welding consumables intended for use on mild steel. Users are responsible for providing consumables for other metals. | |||

* Shop’s TIG welders use 100% Argon Gas. | |||

* | * Beware of mild shock from work table or workpiece if Ground Clamp not attached. | ||

==Set-Up Procedure== | |||

'''1. Safety First''' | |||

* Turn on welding bay ventilation. | |||

* | * Remove flammable materials and water from welding area. | ||

* Protect bystanders from the arc-flash, If you can’t depend on the protective vinyl flaps on the welding bays, use welding screens. | |||

* | * Make sure the workpiece is clean before welding. Flammable substances such as grease and oil can ignite. | ||

'''2. Attach the ground clamp''' to bare metal on the work table. If the workpiece is too large for the work table, clamp the workpiece. | |||

'''3. Outfit your work space''' | |||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | {| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

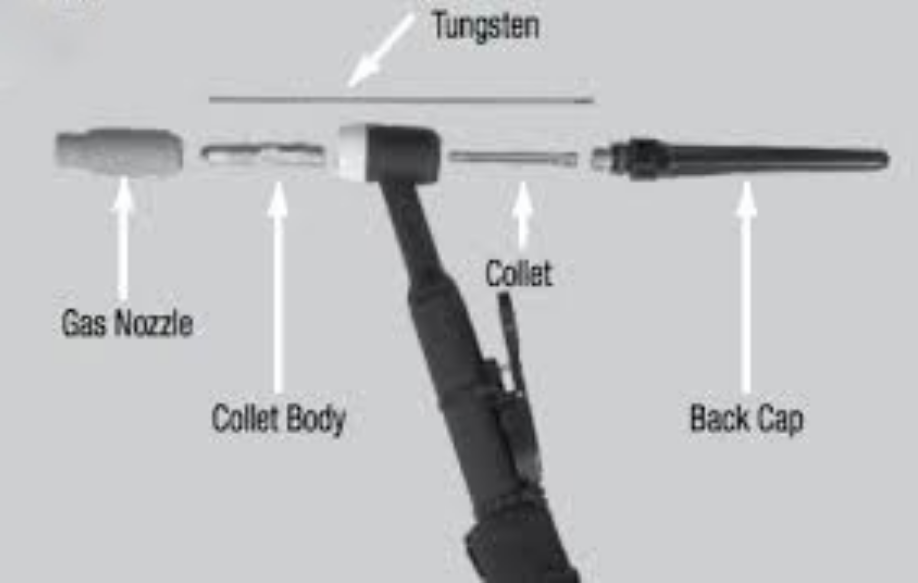

! colspan="2" class="infobox-image" | [[File: | ! colspan="2" class="infobox-image" | [[File:Metal_shop_TIG_welder_torch_exploded.png|300px|TIG torch]] | ||

|- | |- | ||

| colspan="2" | | | colspan="2" | Exploded view of the TIG torch assembly | ||

|- | |- | ||

|} | |} | ||

* '''Filler wire''' is available in the rack on the middle toolbar, outside the two large welding bays. | |||

* '''Check the torch head.''' | |||

Spare torch parts are kept in the Shop’s supply cabinet. | |||

If necessary, insert a fresh tungsten electrode. Tungstens are sharpened on a dedicated pedestal grinder. '''Remember to remove gloves when using the grinder.''' | |||

* | * Assemble other accessories as needed (clamps, magnets, wood TIG blocks, receptacle for hot trash, emergency water bottle (for burn first aid). | ||

'''4.Check to see if the welder has been shut down properly.''' | |||

* Is the power shut off? | * Is the power shut off? | ||

* Is the gas shut off at the cylinder valve? | * Is the gas shut off at the cylinder valve? | ||

'''5. Plug the machine in and turn on.''' | |||

'''6. Turn the gas on.'' If needed, adjust the pressure. | |||

* '''SLOWLY crack the tank valve counterclockwise.''' Watch the regulator needle jump, and check that the needle has stopped moving before opening the valve (about half a turn). This procedure lessens the impact of the initial jump in pressure on the regulator, reducing wear and tear. | |||

* | * Check the regulator dial to make sure the working gas pressure matches the recommendation listed on the shop tag attached to the regulator. Adjust if needed. | ||

Note: if the welder has not been shut down properly by the previous user and the working pressure needs to be lowered, hold the Torch Head away from the workbench (more than 12 inches) and step on the foot control to lower the line pressure and receive an accurate pressure reading. | |||

'''7. Adjust the machine’s settings as necessary for the welding project.''' | |||

* | * '''For welding steel, set to DC negative.''' | ||

* | * '''Set Amperage.''' This setting determines the maximum Amperage when the Foot Petal is fully depressed. (User provides Amperage control through Foot Petal use.) | ||

* When welding steel on the Lincoln Electric Square Wave 175 Pro (red machine), make sure the switch on the front panel is flipped to “TIG,” and the large lever is on “DC —” (or DC Negative). AC polarity is recommended for TIG welding aluminum. | |||

'''8. Test the settings on a piece of scrap metal before proceeding to your project.''' | |||

==Shut-Down Procedure== | |||

'''1. Shut the gas off at the source.''' Turn the cylinder valve clockwise. | |||

'''2. No need to bleed the lines.''' The Shop’s TIG welders use 100% Argon gas, which is non-corrosive. | |||

'''3. Flip the machine’s power switch to “off.” ''' | |||

'''4. If no one is using the nearby bays, turn the ventilation off.''' | |||

== | {| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

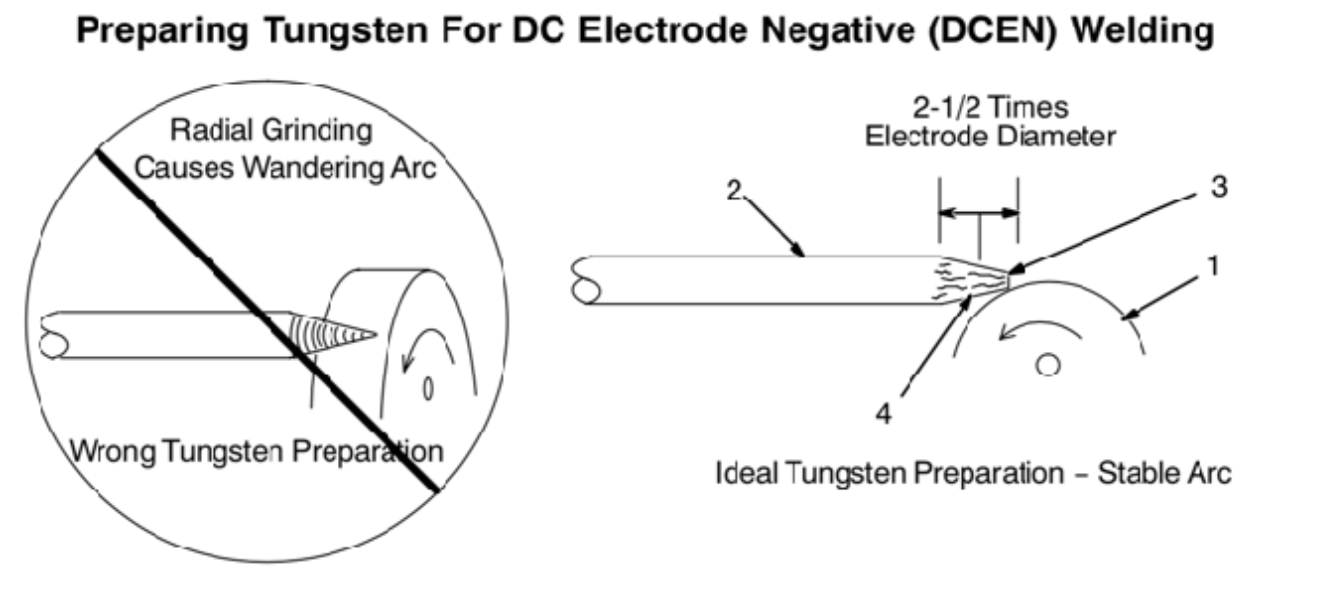

! colspan="2" class="infobox-image" | [[File:Metal_shop_TIG_welder_tungsten_grinding.png|500px|Tungsten grinding]] | |||

|- | |||

| colspan="2" | Incorrect and correct grinding of Tungsten electrodes. | |||

|- | |||

|} | |||

'''5. Return any unusual settings to for the next user.''' (Make sure on DC Neg., and “Pulse” turned off.) | |||

'''6. Loosely Coil the torch cord and store on the work table’s torch hook.''' | |||

'''7. Sharpen used Tungsten.''' Put away all tools and workplace accessories. Clean the work area. | |||

1 - Use the shop’s dedicated pedestal grinder to sharpen / clean end of the tungsten electrode prior to welding. | |||

2 - Grind longitudinally, not tangentially. | |||

3. | 3 - Flat tip. Diameter of this flat determines amperage capacity. | ||

==Videos== | |||

[https://www.youtube.com/watch?v=CWoam95PVCE Destruction caused by a broken cylinder valve] | |||

[https://www.youtube.com/watch?v=ejEJGNLTo84 Mythbusters episode on gas cylinder rocketry] | |||

Revision as of 18:10, 6 February 2024

| Extra precaution required for welders. Training / Tool Testing is essential. See Welding Safety doc. | |

|---|---|

| Eye protection required! | ||

|---|---|---|

| TIG Welders | |

|---|---|

| General Info | |

| Make | Various |

| Model | Various |

| Serial | Unknown |

| Specs | n/a |

| Manual | |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | n/a |

| Training | [https://www.artisansasylum.com/class-

catalog Tool classes] |

| Testing | [https://www.artisansasylum.com/tool-testing Tool

testing], or come to the shop on Tool Testing Night |

| Restrictions | red |

Tools in this category are:

Everlast_Power_TIG_200DV_TIG_Welder "Artemis"

Everlast_Power_TIG_250EX_TIG_Welder "Athena"

Lincoln Electric Square Wave TIG 175 Pro

Equipment Manuals are available for these tools:

Link to: TIG 200DV Manual

Link to: 250EX Manual

Link to: Square Wave 175 Pro Manual

Link to: Synchrowave 200 Manual

Use for:

- Most metals: Steel, stainless, aluminum, titanium, etc.

- The shop provides consumables for mild steel (filler wire, 2% thoriated tungsten). Users provide consumables for other metals.

- See corresponding manufacture manual for each welder’s stick welding capabilities.

Do Not Use for:

- Galvanized, plated, painted, oiled, rusted, or powder coated metals.

Safety Hazards

| |

|---|---|

1. UV damage to eyes. Welding Helmet with shade 10 protection or darker is required. Darker for heavier applications.

2. UV burns on exposed skin. The rays from the arc can cause severe radiation burn (worse than sunburn.) Cover exposed skin.

3. Burns from flame, sparks, hot workpieces. Wear welding gloves, cotton clothing (no synthetics) and closed toe shoes.

4. Poisoning from breathing gases produced by welding. Use ventilation. Do not stick head in fumes. Respirator recommended.

5. Keep workplace clear of flammable materials including grease, oil, solvents, paper.

6. Electrocution if welder is mishandled. Do not weld near puddles of water on floor or work area, especially when using AC output.

* Various safety links to keep you awake at night:

ANSI - General Safety in Welding and Cutting

Operation Notes

- Solvent based metal cleaning should be done with Simple Green or other low-intensity cleaners.

- No brake cleaner. Brake cleaner contains chlorinated hydrocarbons that create phosgene gas when combined with UV light. Ventilation will not prevent poisoning.

- Abrasive cleaning methods are also appropriate.

| |

|---|---|

| TIG welder in the Metal Shop |

- The Shop supplies TIG welding consumables intended for use on mild steel. Users are responsible for providing consumables for other metals.

- Shop’s TIG welders use 100% Argon Gas.

- Beware of mild shock from work table or workpiece if Ground Clamp not attached.

Set-Up Procedure

1. Safety First

- Turn on welding bay ventilation.

- Remove flammable materials and water from welding area.

- Protect bystanders from the arc-flash, If you can’t depend on the protective vinyl flaps on the welding bays, use welding screens.

- Make sure the workpiece is clean before welding. Flammable substances such as grease and oil can ignite.

2. Attach the ground clamp to bare metal on the work table. If the workpiece is too large for the work table, clamp the workpiece.

3. Outfit your work space

| |

|---|---|

| Exploded view of the TIG torch assembly |

- Filler wire is available in the rack on the middle toolbar, outside the two large welding bays.

- Check the torch head.

Spare torch parts are kept in the Shop’s supply cabinet.

If necessary, insert a fresh tungsten electrode. Tungstens are sharpened on a dedicated pedestal grinder. Remember to remove gloves when using the grinder.

- Assemble other accessories as needed (clamps, magnets, wood TIG blocks, receptacle for hot trash, emergency water bottle (for burn first aid).

4.Check to see if the welder has been shut down properly.

- Is the power shut off?

- Is the gas shut off at the cylinder valve?

5. Plug the machine in and turn on.

'6. Turn the gas on. If needed, adjust the pressure.

- SLOWLY crack the tank valve counterclockwise. Watch the regulator needle jump, and check that the needle has stopped moving before opening the valve (about half a turn). This procedure lessens the impact of the initial jump in pressure on the regulator, reducing wear and tear.

- Check the regulator dial to make sure the working gas pressure matches the recommendation listed on the shop tag attached to the regulator. Adjust if needed.

Note: if the welder has not been shut down properly by the previous user and the working pressure needs to be lowered, hold the Torch Head away from the workbench (more than 12 inches) and step on the foot control to lower the line pressure and receive an accurate pressure reading.

7. Adjust the machine’s settings as necessary for the welding project.

- For welding steel, set to DC negative.

- Set Amperage. This setting determines the maximum Amperage when the Foot Petal is fully depressed. (User provides Amperage control through Foot Petal use.)

- When welding steel on the Lincoln Electric Square Wave 175 Pro (red machine), make sure the switch on the front panel is flipped to “TIG,” and the large lever is on “DC —” (or DC Negative). AC polarity is recommended for TIG welding aluminum.

8. Test the settings on a piece of scrap metal before proceeding to your project.

Shut-Down Procedure

1. Shut the gas off at the source. Turn the cylinder valve clockwise.

2. No need to bleed the lines. The Shop’s TIG welders use 100% Argon gas, which is non-corrosive.

3. Flip the machine’s power switch to “off.”

4. If no one is using the nearby bays, turn the ventilation off.

| |

|---|---|

| Incorrect and correct grinding of Tungsten electrodes. |

5. Return any unusual settings to for the next user. (Make sure on DC Neg., and “Pulse” turned off.)

6. Loosely Coil the torch cord and store on the work table’s torch hook.

7. Sharpen used Tungsten. Put away all tools and workplace accessories. Clean the work area.

1 - Use the shop’s dedicated pedestal grinder to sharpen / clean end of the tungsten electrode prior to welding.

2 - Grind longitudinally, not tangentially.

3 - Flat tip. Diameter of this flat determines amperage capacity.

Videos

Pages in category "MIG Welders"

The following 2 pages are in this category, out of 2 total.