Box and Pan Brake and Category:MIG Welders: Difference between pages

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

[[Category:Tools]][[Category:Welders]] | |||

{{ToolBox|tool_title=MIG welders|image=Metal_shop_MIG_welder.png|caption=MIG welder in | |||

[https://www.artisansasylum.com/ | the MEtal Shop|location=Metal Shop|training=[https://www.artisansasylum.com/class- | ||

Night|come to the shop on Tool Testing Night]]|restrictions=red|make=Varied|model=Varied| | catalog Tool classes]|testing=[https://www.artisansasylum.com/tool-testing Tool | ||

testing], or [[:Category:Metal Shop#Tool Testing Night|come to the shop on Tool | |||

Testing Night]]|restrictions=red|make=Varied|model=Varied|serial=Unknown| | |||

manufacturer_specs=n/a|manual=[[Category:MIG_welders#Operation Notes]]|rubric=n/a| | |||

tool_categories=}} | |||

{{Warning|text=Extra precaution required for welders. Training / Tool Testing is | |||

essential. See “Welding Safety” pages.}} | |||

Manufacturers Manuals for each welder is available in the | |||

[https://drive.google.com/drive/folders/1SdAqgZSwBteXBujK4x26A_QXCfu320cW Equipment | |||

Manuals Directory] | |||

== Materials == | == Materials == | ||

'''Use for:''' | |||

* Mild Steel | * Mild Steel '''ONLY''' | ||

'''Do not use for:''' | |||

* Galvanized | |||

* | * Plated | ||

* | * Painted | ||

* | * Oiled | ||

* | * Rusted | ||

* Powder-coated | |||

== Safety Hazards == | == Safety Hazards == | ||

{{EyeWarning}} | {{EyeWarning}} | ||

1. '''UV damage to eyes.''' Welding Helmet with shade 12 protection or darker is required. | |||

2. '''UV burns on exposed skin.''' The rays from the arc can cause severe radiation burn (worse than sunburn.) Cover exposed skin. | |||

3. '''Burns''' from flame, sparks, hot workpieces. Wear welding gloves, cotton clothing (no synthetics) and closed toe shoes. | |||

4. '''Poisoning''' from breathing gases produced by welding. Use ventilation. Do not stick head in fumes. Respirator recommended. | |||

5. Keep workplace clear of flammable materials, including grease, oil, solvents, paper. | |||

6. '''Electrocution''' if welder is mishandled. Do not weld near puddles of water on floor or work area. | |||

== Operation Notes == | == Operation Notes == | ||

* Solvent based metal cleaning should be done with Simple Green or other low-intensity | |||

cleaners. | |||

* Abrasive cleaning methods are also appropriate. | |||

* '''No brake cleaner.''' Brake cleaner contains chlorinated hydrocarbons that create | |||

'''phosgene gas''' when combined with UV light. '''Ventilation will not prevent | |||

poisoning.''' | |||

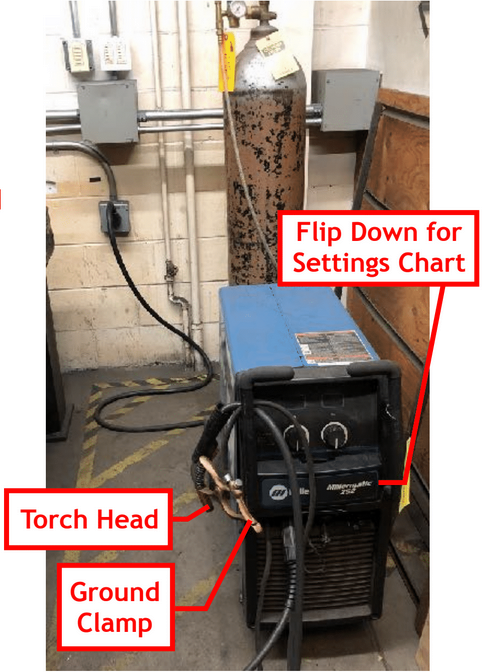

'''MIG Welders Available:''' | |||

* Millermatic 212 Auto Set - welds material from 22 gauge to 3/8 in (9/5mm) thick. | |||

* Millermatic 252- welds material from 22 gauge to 1/2 in. thick. | |||

The shop supplies 025, .030, and .035 inch copper coated steel filler wire. | |||

* The MIG welders in the shop use a gas mixture of 75% Argon and 25% CO2. Purge lines | |||

after use. | |||

* To reduce spatter build-up, lightly coat Torch Head with Nozzle Anti-Spatter Gel. | |||

(Found in welding bays.) | |||

== Set-up Procedure == | |||

1. '''Safety First''' | |||

* Turn on welding bay ventilation. | |||

* Remove flammable materials and water from welding area. | |||

* Protect bystanders from the arc-flash, If you can’t depend on the protective vinyl | |||

flaps on the welding bays, use welding screens | |||

2. '''Attach the ground clamp to bare metal on the work table.''' | |||

If workpiece is too large for the work table, clamp the workpiece. | |||

3. '''Check to see if the welder has been shut down properly.''' | |||

* Is the power shut off? | |||

* Is the gas shut off at the cylinder valve? | |||

* Have the lines been bled (is the working pressure at zero)? | |||

4. '''Plug the machine in and turn it on.''' | |||

5. '''Turn the gas on. If needed, adjust the pressure.''' | |||

* SLOWLY crack the tank valve counterclockwise. Watch the regulator needle jump, and check that the needle has stopped moving before opening the valve (about half a turn). | |||

This procedure lessens the impact of the initial jump in pressure on the regulator, reducing wear and tear. | |||

* Hold the torch away from the workbench (more than 12 inches) and pull the torch trigger to start the gas cycle. | |||

* Check the regulator dial to make sure the working gas pressure matches the recommendation listed on the shop tag attached to the regulator. Adjust if needed. | |||

* Note: An inaccurate working pressure reading may occur if the welder has been shut down improperly by the previous user. Press the trigger on the Torch Head to lower the line pressure and reset the gauge. | |||

6. '''Set the machine's voltage and wire speed.''' | |||

* Take note of the wire size (written on the spool inside the machine) and the thickness of the workpiece. | |||

* | * Start with the settings recommended on the flip down chart located on the front of the machine. Adjust the settings further as needed. | ||

7. '''When welding, avoid tight loops or extra loops in the torch cord.''' | |||

Extra looping will stress the feed mechanisms and may slow down the wire speed. | |||

8. '''Dross may build up on the gas nozzle and/or contact tip while welding.''' | |||

Clean as necessary using MIG pliers. Spare torch parts, including replacement contact tips, are kept in the Metal Shop’s supply cabinet. | |||

== Shut-Down Procedure == | |||

1. '''Shut off the gas at the source.''' Turn the cylinder valve clockwise. | |||

2. '''Bleed the lines.''' | |||

* | * Turn the wire speed down as far as it will go. | ||

* | * Pull the torch trigger and wait for the regulator gauge to read zero. | ||

3. '''Flip the machine's power switch to "off." ''' | |||

4. '''Turn the ventilation off if no one else is using the bays. ''' | |||

5. '''Loosely coil the torch cord and store on the machine. ''' | |||

6. '''Put all tools away and clean the work area. ''' | |||

Revision as of 20:32, 3 February 2024

| MIG welders | |

|---|---|

| General Info | |

| Make | Varied |

| Model | Varied |

| Serial | Unknown |

| Specs | n/a |

| Manual | |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | n/a |

| Training | [https://www.artisansasylum.com/class-

catalog Tool classes] |

| Testing | [https://www.artisansasylum.com/tool-testing Tool

testing], or come to the shop on Tool Testing Night |

| Restrictions | red |

| Extra precaution required for welders. Training / Tool Testing is

essential. See “Welding Safety” pages. | |

|---|---|

Manufacturers Manuals for each welder is available in the

[https://drive.google.com/drive/folders/1SdAqgZSwBteXBujK4x26A_QXCfu320cW Equipment

Manuals Directory]

Materials

Use for:

- Mild Steel ONLY

Do not use for:

- Galvanized

- Plated

- Painted

- Oiled

- Rusted

- Powder-coated

Safety Hazards

| Eye protection required! | ||

|---|---|---|

1. UV damage to eyes. Welding Helmet with shade 12 protection or darker is required.

2. UV burns on exposed skin. The rays from the arc can cause severe radiation burn (worse than sunburn.) Cover exposed skin.

3. Burns from flame, sparks, hot workpieces. Wear welding gloves, cotton clothing (no synthetics) and closed toe shoes.

4. Poisoning from breathing gases produced by welding. Use ventilation. Do not stick head in fumes. Respirator recommended.

5. Keep workplace clear of flammable materials, including grease, oil, solvents, paper.

6. Electrocution if welder is mishandled. Do not weld near puddles of water on floor or work area.

Operation Notes

- Solvent based metal cleaning should be done with Simple Green or other low-intensity

cleaners.

- Abrasive cleaning methods are also appropriate.

- No brake cleaner. Brake cleaner contains chlorinated hydrocarbons that create

phosgene gas when combined with UV light. Ventilation will not prevent

poisoning.

MIG Welders Available:

- Millermatic 212 Auto Set - welds material from 22 gauge to 3/8 in (9/5mm) thick.

- Millermatic 252- welds material from 22 gauge to 1/2 in. thick.

The shop supplies 025, .030, and .035 inch copper coated steel filler wire.

- The MIG welders in the shop use a gas mixture of 75% Argon and 25% CO2. Purge lines

after use.

- To reduce spatter build-up, lightly coat Torch Head with Nozzle Anti-Spatter Gel.

(Found in welding bays.)

Set-up Procedure

1. Safety First

- Turn on welding bay ventilation.

- Remove flammable materials and water from welding area.

- Protect bystanders from the arc-flash, If you can’t depend on the protective vinyl

flaps on the welding bays, use welding screens

2. Attach the ground clamp to bare metal on the work table.

If workpiece is too large for the work table, clamp the workpiece.

3. Check to see if the welder has been shut down properly.

- Is the power shut off?

- Is the gas shut off at the cylinder valve?

- Have the lines been bled (is the working pressure at zero)?

4. Plug the machine in and turn it on.

5. Turn the gas on. If needed, adjust the pressure.

- SLOWLY crack the tank valve counterclockwise. Watch the regulator needle jump, and check that the needle has stopped moving before opening the valve (about half a turn).

This procedure lessens the impact of the initial jump in pressure on the regulator, reducing wear and tear.

- Hold the torch away from the workbench (more than 12 inches) and pull the torch trigger to start the gas cycle.

- Check the regulator dial to make sure the working gas pressure matches the recommendation listed on the shop tag attached to the regulator. Adjust if needed.

- Note: An inaccurate working pressure reading may occur if the welder has been shut down improperly by the previous user. Press the trigger on the Torch Head to lower the line pressure and reset the gauge.

6. Set the machine's voltage and wire speed.

- Take note of the wire size (written on the spool inside the machine) and the thickness of the workpiece.

- Start with the settings recommended on the flip down chart located on the front of the machine. Adjust the settings further as needed.

7. When welding, avoid tight loops or extra loops in the torch cord.

Extra looping will stress the feed mechanisms and may slow down the wire speed.

8. Dross may build up on the gas nozzle and/or contact tip while welding.

Clean as necessary using MIG pliers. Spare torch parts, including replacement contact tips, are kept in the Metal Shop’s supply cabinet.

Shut-Down Procedure

1. Shut off the gas at the source. Turn the cylinder valve clockwise.

2. Bleed the lines.

- Turn the wire speed down as far as it will go.

- Pull the torch trigger and wait for the regulator gauge to read zero.

3. Flip the machine's power switch to "off."

4. Turn the ventilation off if no one else is using the bays.

5. Loosely coil the torch cord and store on the machine.

6. Put all tools away and clean the work area.