Subject matter experts and Cyclone Sand Blaster: Difference between pages

Acharlwood (talk | contribs) mNo edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

[[Category:Tools]] | |||

Link to: [[:Category:Metal Shop | Metal Shop main page]] | |||

{{ToolBox | |||

|tool_title = Sand Blaster | |||

|tool_subtitle = Cyclone Manufacturing | |||

|image = Metal_shop_sandblaster_action_shot.jpg | |||

|caption = A Happy Blaster | |||

|make = Cyclone Manufacturing | |||

|model = DW-7335 | |||

|serial = Unknown | |||

|manufacturer_specs = | |||

|manual = | |||

|location = Metal Shop | |||

|rubric = | |||

|training =[https://www.artisansasylum.com/class-catalog Tool classes] | |||

|testing = [https://www.artisansasylum.com/tool-testing Tool testing], or [[:Category:Metal Shop#Tool Testing | |||

Night|come to the shop on Tool Testing Night]] | |||

|restrictions = green | |||

|tool_categories = | |||

}} | |||

{| class="infobox" cellspacing="0" style="width: 2em; text-align: left; font-size: 125%; line-height: 1.5em;" | |||

! colspan="2" class="infobox-image" | [[File:goggle_mask.png|120px| ]] | |||

|- | |||

| colspan="2" | | |||

|- | |||

|} | |||

== | {| class="infobox" cellspacing="0" style="width: 2em; text-align: left; font-size: 125%; line-height: 1.5em;" | ||

! colspan="2" class="infobox-image" | [[File:_blaster_dust_hazard.png|180px| ]] | |||

|- | |||

| colspan="2" | | |||

|- | |||

|} | |||

{| class="infobox" cellspacing="0" style="width: 2em; text-align: left; font-size: 125%; line-height: 1.5em;" | |||

! colspan="2" class="infobox-image" | [[File:_no_lead_warning.png|180px| ]] | |||

|- | |||

| colspan="2" | | |||

|- | |||

|} | |||

{{EyeWarning}} | |||

=Description= | |||

A sand blaster is a machine that mixes abrasive grains with a jet of compressed air and allows the user to abrade the surface of a part, usually metal. This results in a clean though roughened part free of paint, rust, and other forms of dirt. For smaller parts the blast gun is contained in a glovebox cabinet sealed off from the outside. The user manipulates the tool with thick rubber gloves that pass through the wall of the cabinet. | |||

The sand blaster cabinet at Artisans Asylum is located in a small room within the Metal Shop on the south wall adjacent to the enclosed loading dock. | |||

=Use For= | |||

* Steel | |||

* Stainless Steel | |||

* Zinc-coated steel (Galvanized) | |||

* Aluminum, Titanium, Brass | |||

* Painted metal | |||

* Lightly Rusted Parts | |||

=Do Not Use For= | |||

* Lead-based paints | |||

* Asbestos | |||

* Greasy or Oily Parts | |||

* Massively Rusty Parts | |||

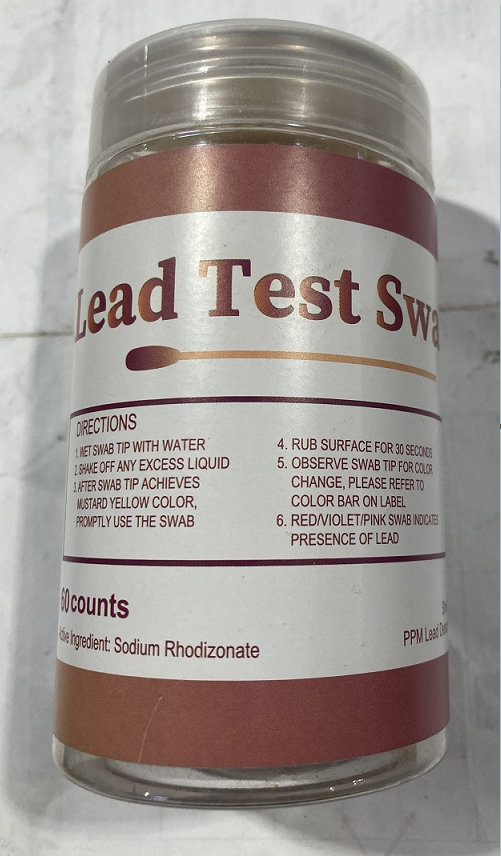

'''Use a lead-test swab to verify that paint if NOT lead-based!''' | |||

'''If the sandblaster becomes contaminated with lead the media must be disposed as [[TOXIC WASTE]] and the cabinet must be thoroughly cleaned out!''' | |||

= | =Safety Notes= | ||

==Personal== | |||

{| class="infobox" cellspacing="0" style="width: 2em; text-align: left; font-size: 125%; line-height: 1.5em;" | |||

! colspan="2" class="infobox-image" | [[File:goggle_mask.png|80px| ]] | |||

|- | |||

| colspan="2" | | |||

|- | |||

|} | |||

* '''Wear safety goggles.''' Eyeglasses don't protect against abrasive dust. | |||

* | * Wear a dust mask or respirator when using the machine or working in the room when the machine is being used. All dust is hazardous to breathe. | ||

* | * Glove-box gloves are at a fixed height above the floor. If they are too high, a stand should be provided. Use care when stepping on and off the stand. | ||

[[ | |||

[[ | * If the blast gun is not properly grounded to the cabinet, static electricity can cause shocks to the operator. If static shocks are encountered, check the ground connection to the gun. | ||

* Do not use silica sand as an abrasive media. The preferred sand blasting media is [https://www.grainger.com/product/Blast-Media-White-Aluminum-53YK23 aluminum oxide.] | |||

* Use caution when lifting heavy parts into the sandblaster cabinet. | |||

* If a part is too large to allow the hatch to close and seal, then do not operate the sandblaster. | |||

* Use caution with the foot pedal and hoses. They are a trip hazard. | |||

==Machine== | |||

* '''Test paints and coatings for [[LEAD]] using the test swabs provided.''' The swabs change from yellow to red when lead is present. If lead is detected do not clean with the sand blaster. | |||

* Do not abrade greasy or oily parts in the sandblaster. These will case the media to clump and clog the flow lines. If it happens, the media must be replaced. | |||

* Place the workpiece in the blast cabinet and close the hatch tightly to avoid dust escaping from the cabinet. When removing workpieces, some dust will unavoidably mix with the room air. Wear a dust mask at all times. | |||

* Do not attempt to move the blast cabinet when it is full of abrasive media. | |||

* Do not point the blast gun at the rubber gloves or the cabinet window. | |||

{| class="infobox" cellspacing="5" style="width: 2em; text-align: left; font-size: 100%; line-height: 1.5em;" | |||

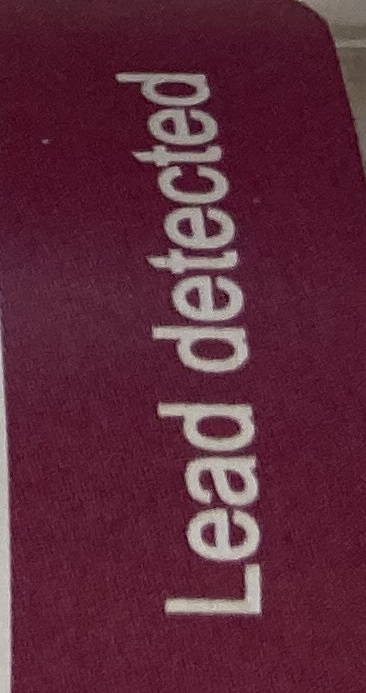

! colspan="2" class="infobox-image" | [[File:Metal_shop_lead_test_YES.jpg|80px|Pb swab color yes lead]] | |||

|- | |||

| colspan="2" | Color if lead is present | |||

|- | |||

|} | |||

{| class="infobox" cellspacing="5" style="width: 2em; text-align: left; font-size: 100%; line-height: 1.5em;" | |||

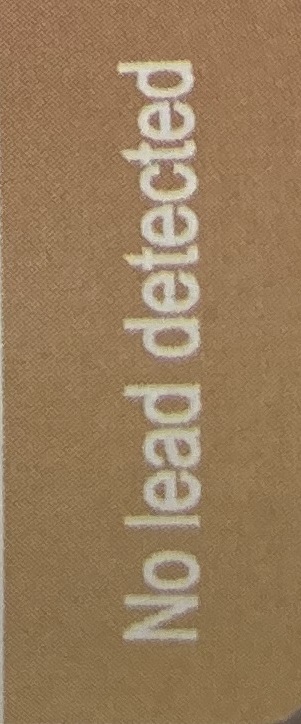

! colspan="2" class="infobox-image" | [[File:Metal_shop_lead_test_NO.jpg|80px|Pb swab color no lead]] | |||

|- | |||

| colspan="2" | Color for no lead | |||

|- | |||

|} | |||

{| class="infobox" cellspacing="5" style="width: 2em; text-align: left; font-size: 100%; line-height: 1.5em;" | |||

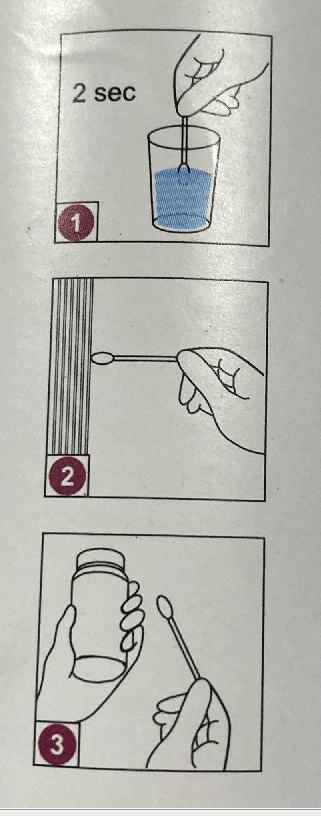

! colspan="2" class="infobox-image" | [[File:Metal_shop_lead_test_swabs.png|100px|Pb swab instruction]] | |||

|- | |||

| colspan="2" | How to Swab | |||

|- | |||

|} | |||

{| class="infobox" cellspacing="5" style="width: 2em; text-align: left; font-size: 100%; line-height: 1.5em;" | |||

! colspan="2" class="infobox-image" | [[File:Metal_shop_lead_test_instructions.png|150px|Pb swabs]] | |||

|- | |||

| colspan="2" | Lead test swabs | |||

|- | |||

|} | |||

Revision as of 17:53, 24 April 2024

Link to: Metal Shop main page

| Sand Blaster | |

|---|---|

| General Info | |

| Make | Cyclone Manufacturing |

| Model | DW-7335 |

| Serial | Unknown |

| Specs | |

| Manual | |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | |

| Training | Tool classes |

| Testing | Tool testing, or [[:Category:Metal Shop#Tool Testing

Night|come to the shop on Tool Testing Night]] |

| Restrictions | green |

| |

|---|---|

| |

|---|---|

| |

|---|---|

| Eye protection required! | ||

|---|---|---|

Description

A sand blaster is a machine that mixes abrasive grains with a jet of compressed air and allows the user to abrade the surface of a part, usually metal. This results in a clean though roughened part free of paint, rust, and other forms of dirt. For smaller parts the blast gun is contained in a glovebox cabinet sealed off from the outside. The user manipulates the tool with thick rubber gloves that pass through the wall of the cabinet.

The sand blaster cabinet at Artisans Asylum is located in a small room within the Metal Shop on the south wall adjacent to the enclosed loading dock.

Use For

- Steel

- Stainless Steel

- Zinc-coated steel (Galvanized)

- Aluminum, Titanium, Brass

- Painted metal

- Lightly Rusted Parts

Do Not Use For

- Lead-based paints

- Asbestos

- Greasy or Oily Parts

- Massively Rusty Parts

Use a lead-test swab to verify that paint if NOT lead-based!

If the sandblaster becomes contaminated with lead the media must be disposed as TOXIC WASTE and the cabinet must be thoroughly cleaned out!

Safety Notes

Personal

| |

|---|---|

- Wear safety goggles. Eyeglasses don't protect against abrasive dust.

- Wear a dust mask or respirator when using the machine or working in the room when the machine is being used. All dust is hazardous to breathe.

- Glove-box gloves are at a fixed height above the floor. If they are too high, a stand should be provided. Use care when stepping on and off the stand.

- If the blast gun is not properly grounded to the cabinet, static electricity can cause shocks to the operator. If static shocks are encountered, check the ground connection to the gun.

- Do not use silica sand as an abrasive media. The preferred sand blasting media is aluminum oxide.

- Use caution when lifting heavy parts into the sandblaster cabinet.

- If a part is too large to allow the hatch to close and seal, then do not operate the sandblaster.

- Use caution with the foot pedal and hoses. They are a trip hazard.

Machine

- Test paints and coatings for LEAD using the test swabs provided. The swabs change from yellow to red when lead is present. If lead is detected do not clean with the sand blaster.

- Do not abrade greasy or oily parts in the sandblaster. These will case the media to clump and clog the flow lines. If it happens, the media must be replaced.

- Place the workpiece in the blast cabinet and close the hatch tightly to avoid dust escaping from the cabinet. When removing workpieces, some dust will unavoidably mix with the room air. Wear a dust mask at all times.

- Do not attempt to move the blast cabinet when it is full of abrasive media.

- Do not point the blast gun at the rubber gloves or the cabinet window.

| |

|---|---|

| Color if lead is present |

| |

|---|---|

| Color for no lead |

| |

|---|---|

| How to Swab |

| |

|---|---|

| Lead test swabs |