M3X CNC Milling Machine

Link to: Machine Shop Main Page

| Eye protection required! | ||

|---|---|---|

| M3X Mill | |

|---|---|

| General Info | |

| Make | CNC Automation |

| Model | M3X |

| Serial | 041721 |

| Specs | {{{manufacturer_specs}}} |

| Manual | Programming manual |

| Asylum Info | |

| Location | Machine Shop |

| Rubric | {{{rubric}}} |

| Training | Tool classes |

| Testing | Tool testing |

| Restrictions | red |

See the Milling Machines category for notes on using all 3-Axis Milling Machines

Description

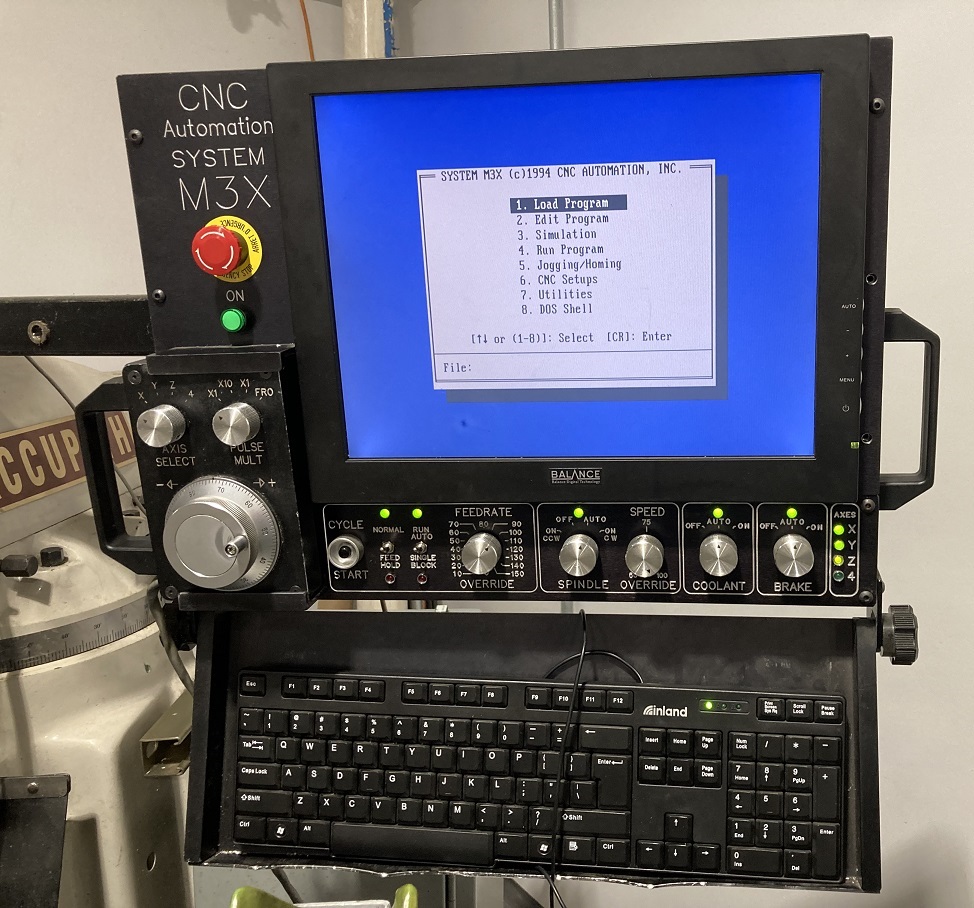

The M3X mill is one of the three operating shop-owned CNC machines in the Antwerp building at Artisans Asylum. It is a 3-axis vertical milling machine fitted with servos and a control system designed by CNC Automation Inc. It is operated by an old-school DOS computer contained in the power box behind the machine. The nameplate on the mill says "Accu II" but its functional name is on the computer panel: "M3X."

The computer controls motion of the mill table in the two horizontal directions, as well as the height of the table. The program for the motion control must be written in G-code created by CAD/CAM software such as may be found in the Machine Shop or the Holton Design Lab.

Programs can be checked by running in a simulation mode which displays the tool movement in a graphics window. Following a successful simulation, the program is then used to drive the milling machine to make a metal part.

Metal workpieces are clamped in a vise and milled with conventional cutting tools. The spindle is raised and lowered manually on this machine, and tools are changed manually.

Safety

Link to: Safety notes on the Milling Machine Category page

| CNC machines are automatically controlled and may start at any time. | |

|---|---|

To Start

| |

|---|---|

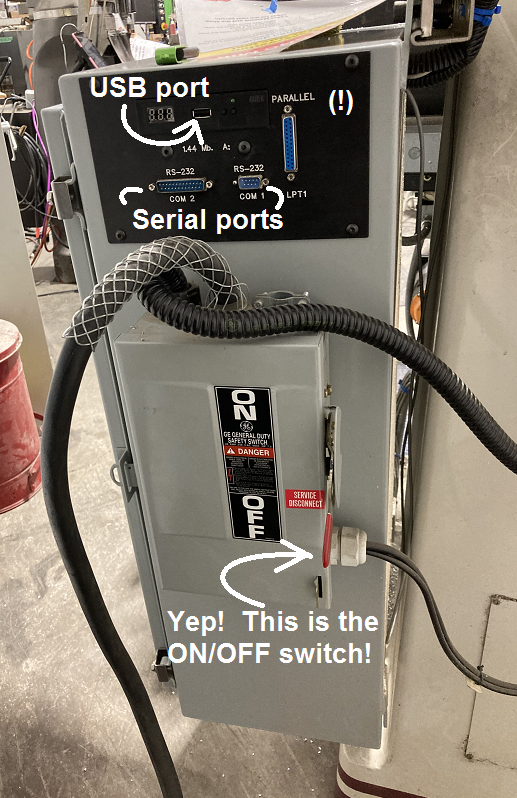

| Power and data for the M3X mill |

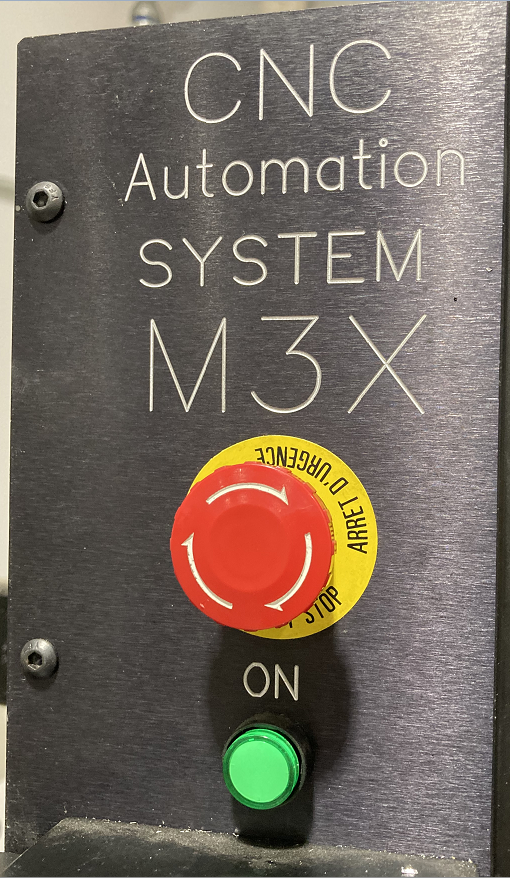

- Make sure the E-STOP button is released. (Turn clockwise)

- Go around the right side of the machine.

- Lift UP the handle on the power box.

- Wait for the computer to boot up.

- Insert a USB drive with a CNC program into the port.

To Stop

| |

|---|---|

| The E-STOP button located to the left of the monitor. |

- Press the E-STOP button on the front panel

OR

- Save your work.

- Quit the program.

- Go around the right side of the machine.

- Push DOWN the power handle.

- Remove any USB drives from the port.

Machine Operation

Take the Training class.

Only students who have passed the training class are qualified to operate this machine.

Machine Programming

On the lowest level, this machine uses text-based programs written in G-code.

| |

|---|---|

| Return with us now to those thrilling days of yesteryear... |

For nearly all practical purposes, the user will design a part in 3D on a CAD system and then run software to convert to the low-level G-code for the CNC mill.

The software that converts high-level CAD data to G-code is generally called a CAM system: Computer Aided Manufacturing.

Installations of both CAD and CAM software may be found in the Machine Shop and the Holton Design Lab.

Users who have enough starch in them may prefer to input G-code directly through the keyboard. This is possible, but far from easy.