Powermatic 201 22-inch Surface Planer: Difference between revisions

From Artisans Asylum Wiki

No edit summary |

No edit summary |

||

| (16 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Tools]][[Category:Wood Shop]] | [[Category:Tools]] | ||

Link to: [[:Category:Wood Shop | Wood Shop main page]] | |||

{{ToolBox | {{ToolBox | ||

|tool_title = | |tool_title = 22-inch Surface Planer | ||

|tool_subtitle = Planer | |tool_subtitle = Planer | ||

|image = Planer_201_in_action.jpg | |image = Planer_201_in_action.jpg | ||

| Line 10: | Line 11: | ||

|serial = Unknown | |serial = Unknown | ||

|manufacturer_specs = | |manufacturer_specs = | ||

|manual = [https:// | |manual = [https://wiki.artisansasylum.com/images/a/a6/Planer_Powermatic_201_22_inch_Manual.pdf 201 Planer User Manual] | ||

|location = Wood Shop | |location = Wood Shop | ||

|rubric = | |rubric = | ||

| Line 22: | Line 23: | ||

{{EyeWarning}} | {{EyeWarning}} | ||

==Description== | |||

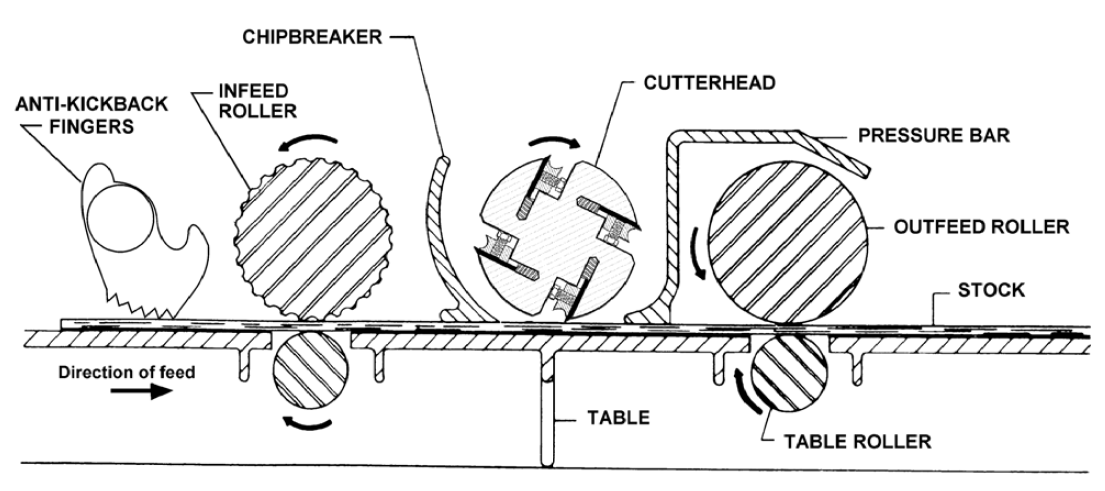

The 22-inch planer in the Wood Shop is nicknamed '''The Beast.''' It has a large powerful horizontal cutter similar to that in the jointer contained within a sturdy housing. Rollers inside the housing grasp the workpiece and feed it at a steady rate under the cutter to grind off or "plane" the top surface of the piece. Because this machine is so powerful, careful precautions must be taken in its use. | |||

==Use For== | ==Use For== | ||

| Line 30: | Line 35: | ||

* Length > 10 inches | * Length > 10 inches | ||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | |||

! colspan="2" class="infobox-image" | [[File:Planer_how_it_works.png|650px|howit works]] | |||

|- | |||

| colspan="2" | Cross-section of the machine. | |||

|- | |||

|} | |||

* Thickness > 3/8" | * Thickness > 3/8" | ||

| Line 39: | Line 50: | ||

* Construction or reclaimed lumber | * Construction or reclaimed lumber | ||

* | * Stuff with nails in it. | ||

* | * Wood with knots, uneven, cross-grain or end-grain | ||

* | * Particle board, laminates, or other composites. | ||

* Boards without a flat surface on at least one side. | |||

''Use the Jointer to flatten one side before planing'' | |||

* Plastics, metals | |||

* Anything stupid. | * Anything stupid. | ||

| Line 65: | Line 82: | ||

* Keep safety guards in place at all times when the machine is in use. | * Keep safety guards in place at all times when the machine is in use. | ||

* '''Do not push the workpiece into the machine.''' | |||

* '''Do not take a depth of cut greater than 1/16 inch.''' This is one full turn on the adjustment wheel. | |||

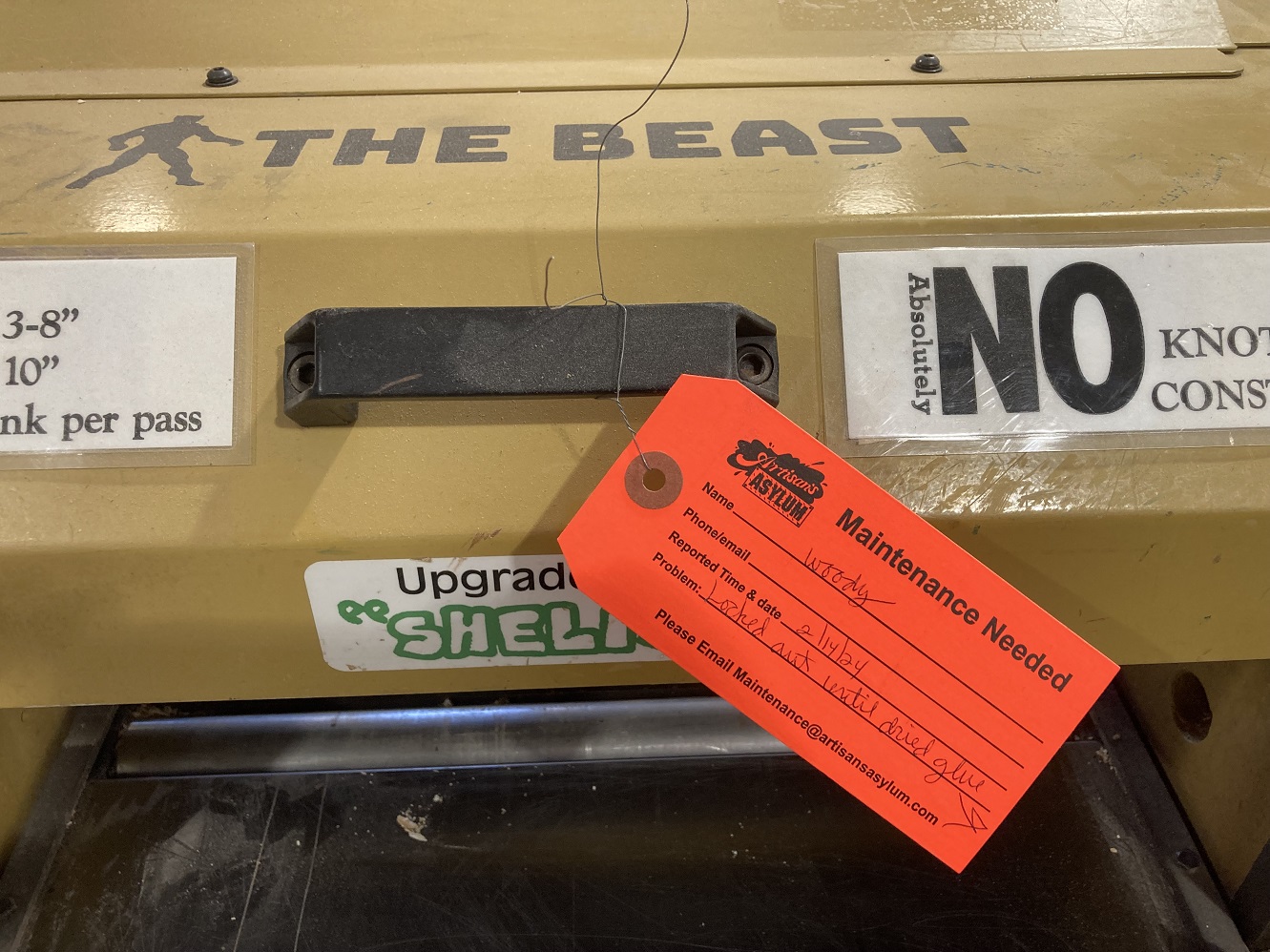

* If the machine is damaged, place a RED tag on it explaining the problem. Do not attempt to fix it yourself. | * If the machine is damaged, place a RED tag on it explaining the problem. Do not attempt to fix it yourself. | ||

| Line 79: | Line 100: | ||

* Do not feed stacked boards. They can kick back. | * Do not feed stacked boards. They can kick back. | ||

* Do not plane a board with loose knots or with nails or any foreign material on its surface. Twisted, warped, or wind-in stock should first be jointed on one surface before attempting to plane a parallel surface on the planer. Serious stock flaws cannot be removed by use of a planer alone. | * Do not plane a board with loose knots or with nails or any foreign material on its surface. | ||

* Twisted, warped, or wind-in stock should first be jointed on one surface before attempting to plane a parallel surface on the planer. Serious stock flaws cannot be removed by use of a planer alone. | |||

* Keep hands outside of the machine. Never reach under the guards to try to clear stock that has stopped feeding. | * Keep hands outside of the machine. Never reach under the guards to try to clear stock that has stopped feeding. | ||

| Line 87: | Line 110: | ||

* Never leave the machine running unattended. | * Never leave the machine running unattended. | ||

''To interpret the results of test cuts, see pp. 16-21 of the [https://drive.google.com/file/d/10a8E4nqSp_wNh7Qiumm5EDxHJQdeAiWw/view?usp=drive_link 201 Planer User Manual.] | |||

Latest revision as of 11:47, 22 March 2024

Link to: Wood Shop main page

| 22-inch Surface Planer | |

|---|---|

| General Info | |

| Make | Powermatic |

| Model | 201 |

| Serial | Unknown |

| Specs | |

| Manual | 201 Planer User Manual |

| Asylum Info | |

| Location | Wood Shop |

| Rubric | |

| Training | |

| Testing | |

| Restrictions | red |

This is a RED tool. Training and tool-testing are required.

| Eye protection required! | ||

|---|---|---|

Description

The 22-inch planer in the Wood Shop is nicknamed The Beast. It has a large powerful horizontal cutter similar to that in the jointer contained within a sturdy housing. Rollers inside the housing grasp the workpiece and feed it at a steady rate under the cutter to grind off or "plane" the top surface of the piece. Because this machine is so powerful, careful precautions must be taken in its use.

Use For

- Hardwood Boards

- Lengthwise grain

- Length > 10 inches

| |

|---|---|

| Cross-section of the machine. |

- Thickness > 3/8"

Do Not Use For

- Pine or Fir or other pitchy wood

- Construction or reclaimed lumber

- Stuff with nails in it.

- Wood with knots, uneven, cross-grain or end-grain

- Particle board, laminates, or other composites.

- Boards without a flat surface on at least one side.

Use the Jointer to flatten one side before planing

- Plastics, metals

- Anything stupid.

Safety Notes

| |

|---|---|

- Wear safety goggles. Eyeglasses are NOT safety goggles.

- This machine is LOUD. Wear hearing protection.

- No loose clothing, neckties, rings, or other jewelry. Roll up sleeves. Wear shoes with good traction. Do not wear gloves.

- Switch on the dust collector before feeding stock into the machine. It is a Coral AF/2C two-filter collector shared with the Powermatic 1696 Jointer.

- Keep safety guards in place at all times when the machine is in use.

- Do not push the workpiece into the machine.

- Do not take a depth of cut greater than 1/16 inch. This is one full turn on the adjustment wheel.

- If the machine is damaged, place a RED tag on it explaining the problem. Do not attempt to fix it yourself.

| |

|---|---|

| Maintenance Request Tag. |

- Maintain a balanced stance at all times so that you do not fall or lean against moving parts. Do not overreach or use excessive force to perform any machine operation.

- Do not feed stacked boards. They can kick back.

- Do not plane a board with loose knots or with nails or any foreign material on its surface.

- Twisted, warped, or wind-in stock should first be jointed on one surface before attempting to plane a parallel surface on the planer. Serious stock flaws cannot be removed by use of a planer alone.

- Keep hands outside of the machine. Never reach under the guards to try to clear stock that has stopped feeding.

- When starting a cut, do not have any part of the hands under that part of the board that is over the table; the infeed roller will engage the board and force it down against the table causing a pinching action.

- Never leave the machine running unattended.

To interpret the results of test cuts, see pp. 16-21 of the 201 Planer User Manual.