South Bend Manual Lathe: Difference between revisions

(add belt/pulley picture) |

(add spindle image) |

||

| Line 54: | Line 54: | ||

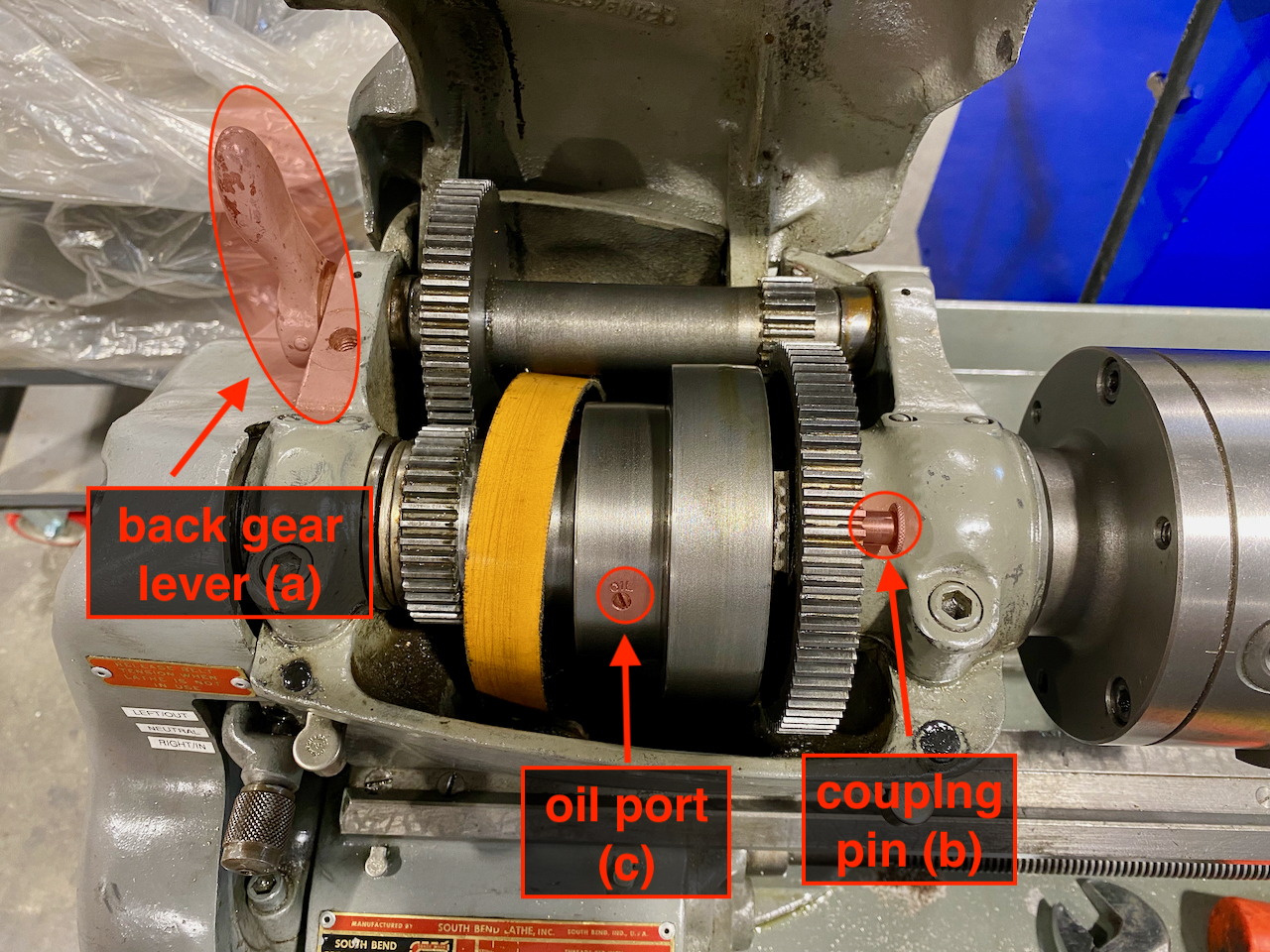

To disable the back gear, move the back gear lever to the rear to disengage the back gear and re-insert the coupling pin. Ensure that the pin is fully seated in the cutout, which is in-line with the oil port on the middle spindle pulley. | To disable the back gear, move the back gear lever to the rear to disengage the back gear and re-insert the coupling pin. Ensure that the pin is fully seated in the cutout, which is in-line with the oil port on the middle spindle pulley. | ||

[[File:Sb back gear and locking pin.jpeg|alt=Overview of the South Bend headstock spindle controls|thumb|Overview of the headstock spindle controls on the South Bend lathe. To engage back gear, pull the back gear lever (a) towards the front of the lathe and pull out the coupling pin (b). To disengage back gear, push the back gear lever towards the rear of the lathe and push in the coupling pin. Align the coupling pin with the oil port (c) before trying to push the coupling pin back into place.]] | |||

[picture of back gear mechanism and oil port] | [picture of back gear mechanism and oil port] | ||

Revision as of 20:14, 12 April 2024

Link to: Machine Shop Main Page

| Eye protection required! | ||

|---|---|---|

| South Bend Lathe | |

|---|---|

| General Info | |

| Make | South Bend |

| Model | |

| Serial | |

| Specs | |

| Manual | Textbook |

| Asylum Info | |

| Location | Machine Shop |

| Rubric | N/A |

| Training | |

| Testing | Tool testing |

| Restrictions | red |

See the Lathes category for notes on using all lathes

Safety

Link to: Safety notes on the Metal-cutting lathes category page

Changing the spindle speed

| |

|---|---|

| The South Bend lathe gear-box |

This lathe features manual speed-changing where the user actually manipulates belts and gears inside the gearbox itself.

Do not attempt to adjust these items unless you have been properly trained and tool-tested.

Belts and Pulleys

The South Bend has two belts. The V-belt between the motor and the lathe drive shifts between high range and low range, and the flat belt between the lathe drive and the spindle allows adjustments within these ranges. To adjust the speed, loosen the belt tension lever on the left side of the machine, then move the belts to achieve the appropriate speed. Tighten the belt tension when you're ready to use the lathe

[picture of belt tension lever] [picture/chart of lathe speeds]

Back Gear

The back gear control on the lathe allows low speed, high torque rotation. To use the back gear, pull the back gear lever until the back gears engage with the spindle gear. If the gears are not meshing, manually spin the chuck while pulling the back gear lever to the rear.

Next, pull the coupling pin out of the largest drive gear. If you don't remove this pin, the chuck and gears will be locked. This will prevent the spindle from turning, and it's useful for loosening the chucks, but operating the lathe in this condition will cause the belts to rub.

The additional mechanical components in the back gear drivetrain creates more mechanical, gear-clanging noise. This noise is normal, but grinding or rubbing noises are not. Stop the lathe if you hear these kinds of noises.

To disable the back gear, move the back gear lever to the rear to disengage the back gear and re-insert the coupling pin. Ensure that the pin is fully seated in the cutout, which is in-line with the oil port on the middle spindle pulley.

[picture of back gear mechanism and oil port]