Category:TIG Welders: Difference between revisions

No edit summary |

No edit summary |

||

| Line 13: | Line 13: | ||

manufacturer_specs=n/a|manual=[[Category:MIG_Welders#Operation Notes]]|rubric=n/a| | manufacturer_specs=n/a|manual=[[Category:MIG_Welders#Operation Notes]]|rubric=n/a| | ||

tool_categories=}} | tool_categories=}} | ||

==Use for:== | |||

* Most metals: Steel, stainless, aluminum, titanium, etc. | |||

* '''The shop provides consumables for mild steel''' (filler wire, 2% thoriated tungsten). Users provide consumables for other metals. | |||

* See corresponding manufacture manual for each welder’s stick welding capabilities. | |||

==Do Not Use for:== | |||

* Galvanized, plated, painted, oiled, rusted, or powder coated metals. | |||

== Safety Hazards == | |||

{| class="infobox" cellspacing="0" style="width: 2em; text-align: left; font-size: 125%; line-height: 1.5em;" | |||

! colspan="2" class="infobox-image" | [[File:Helmet_gloves.png|60px| ]] | |||

|- | |||

| colspan="2" | | |||

|- | |||

|} | |||

1. '''UV damage to eyes.''' Welding Helmet with shade 10 protection or darker is required. Darker for heavier applications. | |||

2. '''UV burns on exposed skin.''' The rays from the arc can cause severe radiation burn (worse than sunburn.) Cover exposed skin. | |||

3. '''Burns''' from flame, sparks, hot workpieces. Wear welding gloves, cotton clothing (no synthetics) and closed toe shoes. | |||

4. '''Poisoning''' from breathing gases produced by welding. Use ventilation. ''Do not stick head in fumes.'' Respirator recommended. | |||

5. Keep workplace '''clear of flammable materials''' including grease, oil, solvents, paper. | |||

6. '''Electrocution''' if welder is mishandled. Do not weld near puddles of water on floor or work area, especially when using AC output. | |||

==Operation Notes== | |||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | |||

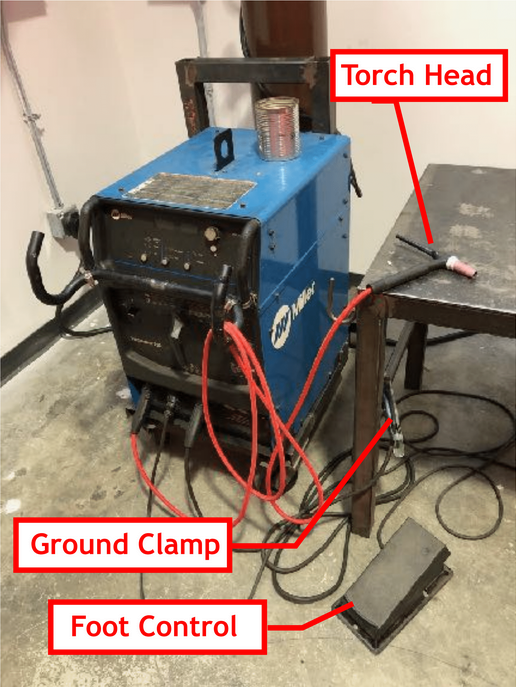

! colspan="2" class="infobox-image" | [[File:Metal_shop_TIG_welder_labels.png|350px|TIG welder]] | |||

|- | |||

| colspan="2" | TIG welder in the Metal Shop | |||

|- | |||

|} | |||

* '''Solvent based metal cleaning should be done with Simple Green or other low-intensity cleaners.''' | |||

* '''No brake cleaner.''' Brake cleaner contains chlorinated hydrocarbons that create '''phosgene gas''' when combined with UV light. ''Ventilation will not prevent poisoning.'' | |||

* Abrasive cleaning methods are also appropriate. | |||

* '''TIG Welders Available:''' | |||

Miller Syncrowave 200 | |||

Lincoln Electric Square Wave TIG 175 PRO (code #10732) | |||

Everlast Powertig 200DV | |||

Everlast Powertig 250EX. | |||

* The Shop supplies TIG welding consumables intended for use on mild steel. Users are responsible for providing consumables for other metals. | |||

* Shop’s TIG welders use 100% Argon Gas. | |||

* Beware of mild shock from work table or workpiece if Ground Clamp not attached. | |||

Revision as of 18:00, 5 February 2024

| Extra precaution required for welders. Training / Tool Testing is essential. See Welding Safety doc. | |

|---|---|

| Eye protection required! | ||

|---|---|---|

| TIG Welders | |

|---|---|

| General Info | |

| Make | Varied |

| Model | Varied |

| Serial | Unknown |

| Specs | n/a |

| Manual | |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | n/a |

| Training | [https://www.artisansasylum.com/class-

catalog Tool classes] |

| Testing | [https://www.artisansasylum.com/tool-testing Tool

testing], or come to the shop on Tool Testing Night |

| Restrictions | red |

Use for:

- Most metals: Steel, stainless, aluminum, titanium, etc.

- The shop provides consumables for mild steel (filler wire, 2% thoriated tungsten). Users provide consumables for other metals.

- See corresponding manufacture manual for each welder’s stick welding capabilities.

Do Not Use for:

- Galvanized, plated, painted, oiled, rusted, or powder coated metals.

Safety Hazards

| |

|---|---|

1. UV damage to eyes. Welding Helmet with shade 10 protection or darker is required. Darker for heavier applications.

2. UV burns on exposed skin. The rays from the arc can cause severe radiation burn (worse than sunburn.) Cover exposed skin.

3. Burns from flame, sparks, hot workpieces. Wear welding gloves, cotton clothing (no synthetics) and closed toe shoes.

4. Poisoning from breathing gases produced by welding. Use ventilation. Do not stick head in fumes. Respirator recommended.

5. Keep workplace clear of flammable materials including grease, oil, solvents, paper.

6. Electrocution if welder is mishandled. Do not weld near puddles of water on floor or work area, especially when using AC output.

Operation Notes

| |

|---|---|

| TIG welder in the Metal Shop |

- Solvent based metal cleaning should be done with Simple Green or other low-intensity cleaners.

- No brake cleaner. Brake cleaner contains chlorinated hydrocarbons that create phosgene gas when combined with UV light. Ventilation will not prevent poisoning.

- Abrasive cleaning methods are also appropriate.

- TIG Welders Available:

Miller Syncrowave 200 Lincoln Electric Square Wave TIG 175 PRO (code #10732) Everlast Powertig 200DV Everlast Powertig 250EX.

- The Shop supplies TIG welding consumables intended for use on mild steel. Users are responsible for providing consumables for other metals.

- Shop’s TIG welders use 100% Argon Gas.

- Beware of mild shock from work table or workpiece if Ground Clamp not attached.

Pages in category "TIG Welders"

The following 4 pages are in this category, out of 4 total.