Roller Tube Bender: Difference between revisions

From Artisans Asylum Wiki

No edit summary |

No edit summary |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Tools]][[Category:Metal Shop]] | [[Category:Tools]][[Category:Metal Shop]] | ||

Link to: [[:Category:Metal Shop | Metal Shop main page]] | |||

Link to: [[:Category:Metal Shop#Tools | Metal Shop tool list]] | |||

{{ToolBox|tool_title=TR-50 Roller Tube Bender|image=Metal_shop_roller_tube_bender.png|caption=Roller tube bender| | {{ToolBox|tool_title=TR-50 Roller Tube Bender|image=Metal_shop_roller_tube_bender.png|caption=Roller tube bender| | ||

location=Metal Shop|training=[https://www.artisansasylum.com/class-catalog Tool classes]|testing= | location=Metal Shop|training=[https://www.artisansasylum.com/class-catalog Tool classes]|testing= | ||

[https://www.artisansasylum.com/tool-testing Tool testing], or [[:Category:Metal Shop#Tool Testing | [https://www.artisansasylum.com/tool-testing Tool testing], or [[:Category:Metal Shop#Tool Testing Night|come to the shop on Tool Testing Night]]|restrictions=green|make=|model=| | ||

Night|come to the shop on Tool Testing Night]]|restrictions=green|make=|model=| | serial=Unknown|manufacturer_specs=n/a|manual=[https://drive.google.com/file/d/1lErLSx96-U_PiARGcBanr1KxwAim4ayO/view?usp=drive_link Roller BenderManual]|rubric=n/a|tool_categories=}} | ||

serial=Unknown|manufacturer_specs=n/a|manual=[https://drive.google.com/file/d/1lErLSx96-U_PiARGcBanr1KxwAim4ayO/view?usp=drive_link Roller | |||

==Use for:== | ==Use for:== | ||

| Line 16: | Line 18: | ||

* Do not bend wrong tube sizes with a given die set. Die sets are specific to tube size. | * Do not bend wrong tube sizes with a given die set. Die sets are specific to tube size. | ||

==Hazard Analysis== | ==Hazard Analysis== | ||

| Line 28: | Line 28: | ||

* Cuts / Scrapes / bruises if care is not taken to prevent metal stock from slipping during the bending process. | * Cuts / Scrapes / bruises if care is not taken to prevent metal stock from slipping during the bending process. | ||

{{EyeWarning}} | |||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | {| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

Latest revision as of 21:07, 5 September 2024

Link to: Metal Shop main page

Link to: Metal Shop tool list

| TR-50 Roller Tube Bender | |

|---|---|

| General Info | |

| Make | |

| Model | |

| Serial | Unknown |

| Specs | n/a |

| Manual | Roller BenderManual |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | n/a |

| Training | Tool classes |

| Testing | Tool testing, or come to the shop on Tool Testing Night |

| Restrictions | green |

Use for:

- Rolling / bending metal tube (measured by outside diameter).

- The shop owns a limited number of die sets, including a 1” square tube die set.

Do Not Use for:

- Do not bend wrong tube sizes with a given die set. Die sets are specific to tube size.

Hazard Analysis

- Eye protection required. (Metal can snap while bending, and flakes of rust, mill scale, or paint can become airborne.

- Cuts / Scrapes from sharp cut edges of the workpiece. Use of gloves is acceptable when using this machine.

- Pinched fingers, skin.

- Cuts / Scrapes / bruises if care is not taken to prevent metal stock from slipping during the bending process.

| Eye protection required! | ||

|---|---|---|

| |

|---|---|

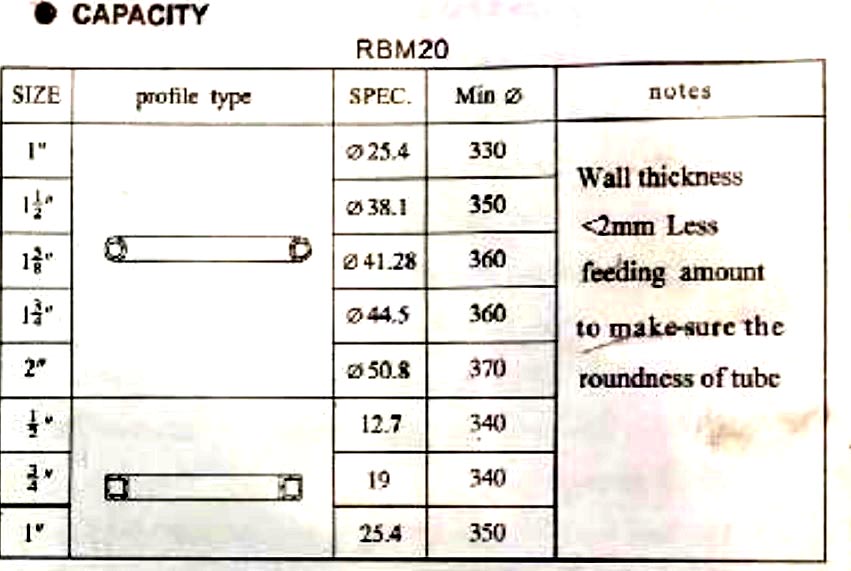

| Tube diameters of available rollers. |

Notes and Best Practices

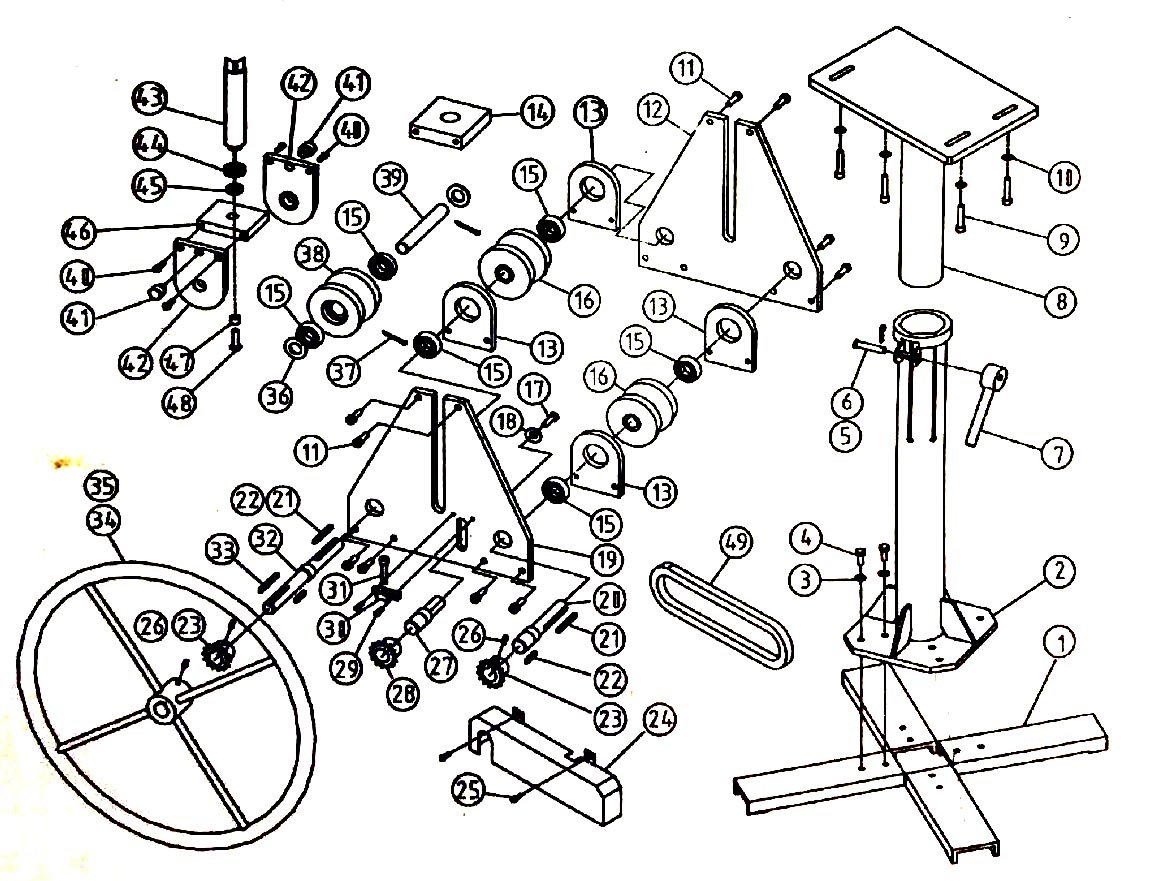

Piece numbers refer to the exploded view below.

- The bearings need frequent lubrication and should be checked regularly.

- To change the lower rollers (16), remove the back frame (12) by unscrewing screws 11 and 9. Remove the cotter pin (37) and washer (36).

- To change the upper roller (38) remove the cotter pin (39).

- With thinner tube, less pressure and a slower feed rate may be require prevent tube compression.

- Tighten or loosen the chain by adjusting the Chain Adjustment Screw (31).

| |

|---|---|

| Exploded view of the roller bender |

Basic Operation Instructions

1. Loosen the Screw Rod (43) at the top of the machine.

2. Insert workpiece into the Rollers, and use the Hand Wheel to move the tube through the machine.

3. Tighten the Screw Rod, and roll in the opposite direction.

4. Repeat the back and forth rolling process until the desired bend is achieved.