Brackets Tutorial 4: Basic Cardboard Aided Design: Difference between revisions

From Artisans Asylum Wiki

No edit summary |

No edit summary |

||

| Line 5: | Line 5: | ||

=Introduction= | =Introduction= | ||

Some people may find it easier to make a cardboard prototype of a sheet metal part rather than designing it in CAD. This tutorial shows how to convert a cardboard prototype into an image file and upload it to the CNC plasma cutter. | |||

=Prototyping= | |||

If you don't have the time or the inclination to use a CAD system or a 3D printer, you can perform what we call "Rapid Prototyping" using drafting tools and paints. | |||

Cut a cardboard prototype as shown at actual size. Make sure it is colored either bright white or deep black to ease the scanning step. Note the dangling feature along the bottom edge, which is folded to make an angle brace. | |||

Holes are defined by drawing spots of the contrasting color. | |||

[[File:Tut4_cutting_cardboard.png|300px|cutting]] | [[File:Tut4_cutting_cardboard.png|300px|cutting]] | ||

Revision as of 15:25, 17 November 2024

Link to: Bracketage Main Page

Introduction

Some people may find it easier to make a cardboard prototype of a sheet metal part rather than designing it in CAD. This tutorial shows how to convert a cardboard prototype into an image file and upload it to the CNC plasma cutter.

Prototyping

If you don't have the time or the inclination to use a CAD system or a 3D printer, you can perform what we call "Rapid Prototyping" using drafting tools and paints.

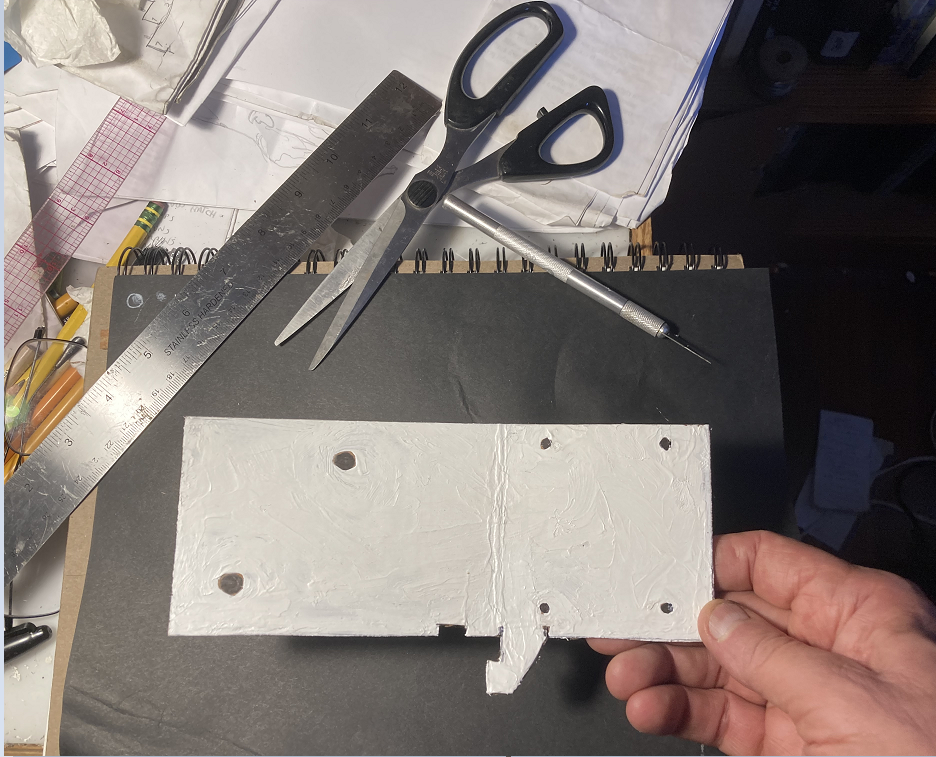

Cut a cardboard prototype as shown at actual size. Make sure it is colored either bright white or deep black to ease the scanning step. Note the dangling feature along the bottom edge, which is folded to make an angle brace.

Holes are defined by drawing spots of the contrasting color.