Box and Pan Brake: Difference between revisions

From Artisans Asylum Wiki

No edit summary |

Acharlwood (talk | contribs) (Added category) |

||

| (11 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Tools]][[Category:Metal Shop]] | |||

Link to: [[:Category:Metal Shop | Metal Shop main page]] | |||

Link to: [[:Category:Metal Shop#Tools | Metal Shop tool list]] | |||

Night|come to the shop on Tool Testing Night]]|restrictions= | {{ToolBox|tool_title=Box and Pan Brake|image=Metal_shop_brake_nolabels.jpg|caption=Box and Pan Brake|location=Metal Shop|training=[https://www.artisansasylum.com/class-catalog Tool classes]|testing=[https://www.artisansasylum.com/tool-testing Tool testing], or [[:Category:Metal Shop#Tool Testing Night|come to the shop on Tool Testing Night]]|restrictions=green|make=Varied|model=Varied|serial=Unknown|manufacturer_specs=n/a|manual=n/a|rubric=n/a|tool_categories=[[Category:Metal_Brakes]]}} | ||

serial=Unknown|manufacturer_specs=n/a|manual=n/a|rubric=n/a|tool_categories=}} | |||

== Materials == | == Materials == | ||

| Line 18: | Line 16: | ||

=== Do not use for: === | === Do not use for: === | ||

* Sheet metal exceeding 1/32" | * Sheet metal exceeding 1/32" thickness | ||

* Stainless steel | * Stainless steel | ||

* High-carbon or Hardened steel | * High-carbon or Hardened steel | ||

| Line 24: | Line 22: | ||

== Safety Hazards == | == Safety Hazards == | ||

{{EyeWarning}} | {{EyeWarning}} | ||

| Line 31: | Line 30: | ||

* Cuts/scrapes from sharp edges and burrs | * Cuts/scrapes from sharp edges and burrs | ||

== Operation Notes == | |||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | {| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

! colspan="2" class="infobox-image" | [[File:Metal_shop_brake.jpg| | ! colspan="2" class="infobox-image" | [[File:Metal_shop_brake.jpg|450px|Brake]] | ||

|- | |- | ||

| colspan="2" | Metal Shop Sheet Metal Brake | | colspan="2" | Metal Shop Sheet Metal Brake | ||

| Line 39: | Line 41: | ||

|} | |} | ||

* Brake maximum capacity – 22 GA x 48” width | * Brake maximum capacity – 22 GA x 48” width | ||

| Line 52: | Line 53: | ||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | {| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

! colspan="2" class="infobox-image" | [[File:Metal_shop_brake_parts.jpg| | ! colspan="2" class="infobox-image" | [[File:Metal_shop_brake_parts.jpg|450px|Brake Parts]] | ||

|- | |- | ||

| colspan="2" | Parts of the Brake | | colspan="2" | Parts of the Brake | ||

| Line 77: | Line 78: | ||

== Video == | == Video == | ||

[www.youtube.com/watch?v=d4RWkf7eo1g Box and Pan Brake] | [https://www.youtube.com/watch?v=d4RWkf7eo1g '''Box and Pan Brake'''] | ||

Latest revision as of 15:53, 5 April 2025

Link to: Metal Shop main page

Link to: Metal Shop tool list

| Box and Pan Brake | |

|---|---|

| General Info | |

| Make | Varied |

| Model | Varied |

| Serial | Unknown |

| Specs | n/a |

| Manual | n/a |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | n/a |

| Training | Tool classes |

| Testing | Tool testing, or come to the shop on Tool Testing Night |

| Restrictions | green |

Materials

Use for:

- Up to 22 Ga sheet metal (1/32")

- Mild Steel

- Soft Metals

Do not use for:

- Sheet metal exceeding 1/32" thickness

- Stainless steel

- High-carbon or Hardened steel

- Round or square stock

Safety Hazards

| Eye protection required! | ||

|---|---|---|

- Workpiece can unexpectedly snap

- Pinching injuries

- Cuts/scrapes from sharp edges and burrs

Operation Notes

| |

|---|---|

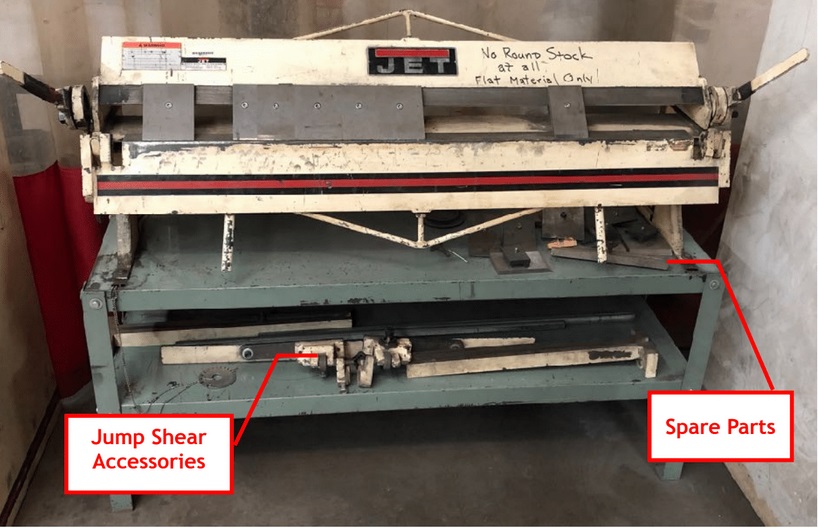

| Metal Shop Sheet Metal Brake |

- Brake maximum capacity – 22 GA x 48” width

- Attached gauge wheel is used to judge if your material is appropriate for the machine.

- Spare parts, including an Allen wrench, are stored underneath.

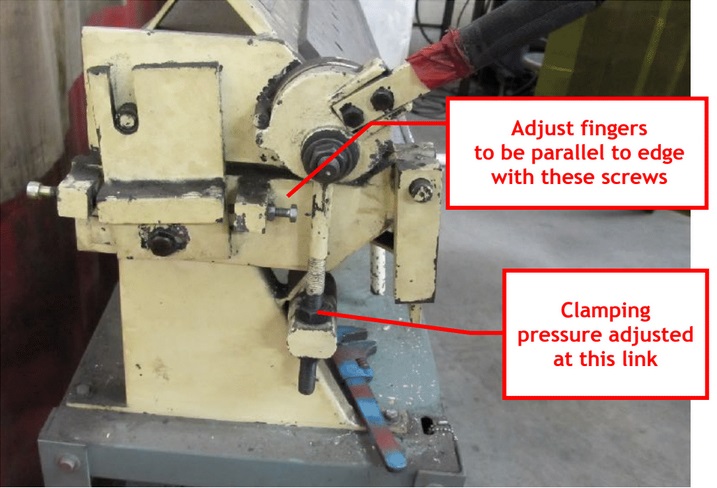

- A 6 mm Allen wrench is used to adjust fingers. The proper size wrench will help to prolong the life of the screw heads.

Basic Operating Instructions

| |

|---|---|

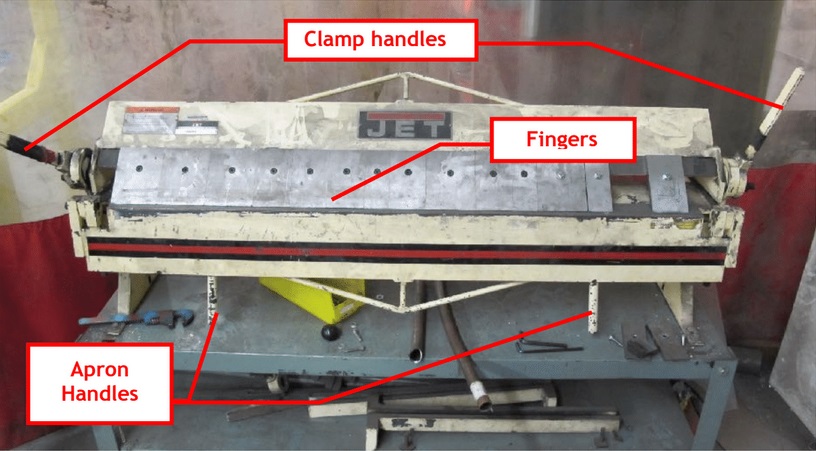

| Parts of the Brake |

| |

|---|---|

| Adjusting the Brake |

- Align fingers by loosening all, then raising the apron to line them up. Re-tighten.

- Place sheet metal under fingers and position as needed.

- Use a 6 mm Allen wrench to adjust fingers 1/18” to 1/16” from edge. Material width from edge is a good rule of thumb.

- Lock your material by pressing both clamp handles down. (Left one is bent, and tricky)

- To bend sheet metal, grab Apron Handles and lift. (Remember, steel has spring-back.)