Powermatic PJ1696 Jointer: Difference between revisions

No edit summary |

|||

| (20 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Tools]][[Category:Wood Shop]] | [[Category:Tools]] | ||

Link to: [[:Category:Wood Shop | Wood Shop main page]] | |||

{{ToolBox | {{ToolBox | ||

| Line 10: | Line 11: | ||

|serial = Unknown | |serial = Unknown | ||

|manufacturer_specs = | |manufacturer_specs = | ||

|manual = [ | |manual = [[media: Jointer_Powermatic_PJ1696_16_inch_Manual.pdf | Jointer User Manual]] | ||

|location = Wood Shop | |location = Wood Shop | ||

|rubric = | |rubric = | ||

| Line 19: | Line 20: | ||

}} | }} | ||

'''This is a | '''This is a <span style="color:red">red</span> tool. Training and tool-testing are required.''' | ||

{{EyeWarning}} | |||

==Description== | |||

A jointer has a similar architecture to a table saw. Workpieces are fed by hand on a flat table and a rotating cutter projects through the table top. Unlike a table saw, the jointer cutter is cylindrical and mills the bottom surface of the workpiece to flatten it out. | |||

==Use For== | ==Use For== | ||

| Line 26: | Line 33: | ||

Length > 8 inches | Length > 8 inches | ||

{| class="infobox" cellspacing="5" style="width: 12em; text-align: left; font-size: 100%; line-height: 1.5em;" | |||

! colspan="2" class="infobox-image" | [[File:Jointer_nolabels.jpg|320px|Jointer nolabels]] | |||

|- | |||

| colspan="2" | The Powermatic Jointer waiting to be used | |||

|- | |||

|} | |||

{| class="infobox" cellspacing="5" style="width: 12em; text-align: left; font-size: 100%; line-height: 1.5em;" | |||

! colspan="2" class="infobox-image" | [[File:Jointer_knife_rotor.png|220px|Jointer knives]] | |||

|- | |||

| colspan="2" | WHIRLING KNIVES! | |||

|- | |||

|} | |||

Width > 3/4" | Width > 3/4" | ||

| Line 40: | Line 61: | ||

Metals | Metals | ||

==Safety Notes== | ==Safety Notes== | ||

| Line 48: | Line 67: | ||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | {| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

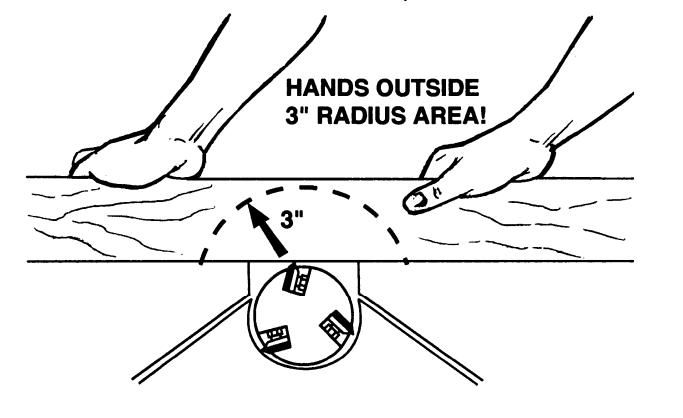

! colspan="2" class="infobox-image" | [[File:Jointer_three_inch_hand_radius.png| | ! colspan="2" class="infobox-image" | [[File:Jointer_three_inch_hand_radius.png|320px|Jointer 3 inch]] | ||

|- | |- | ||

| colspan="2" | Don't chop off your fingers! | | colspan="2" | Don't chop off your fingers! | ||

| Line 80: | Line 99: | ||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | {| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

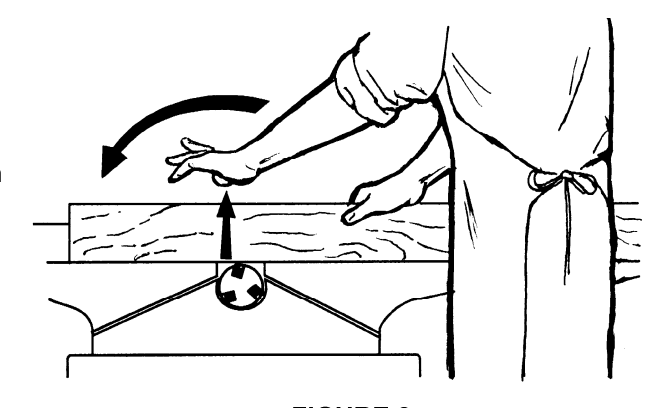

! colspan="2" class="infobox-image" | [[File:Jointer_hand_choreography.png| | ! colspan="2" class="infobox-image" | [[File:Jointer_hand_choreography.png|320px|Jointer hand choreography]] | ||

|- | |- | ||

| colspan="2" | Shift hands during cut. MAINTAIN PRESSURE ON THE WORKPIECE. | | colspan="2" | Shift hands during cut. MAINTAIN PRESSURE ON THE WORKPIECE. | ||

| Line 104: | Line 123: | ||

2. Turn the cutter head until one row of knives is at its highest point. | 2. Turn the cutter head until one row of knives is at its highest point. | ||

3. Lower the outfeed table until the straight edge contacts a knife blade. Rock the head slightly to make sure the apex of the knife is contacting the straight edge. | |||

4. Lock the outfeed table at this setting. | |||

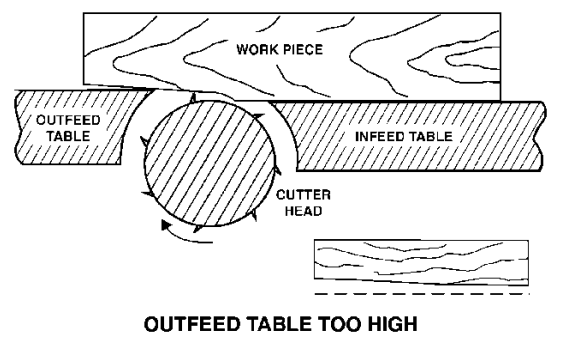

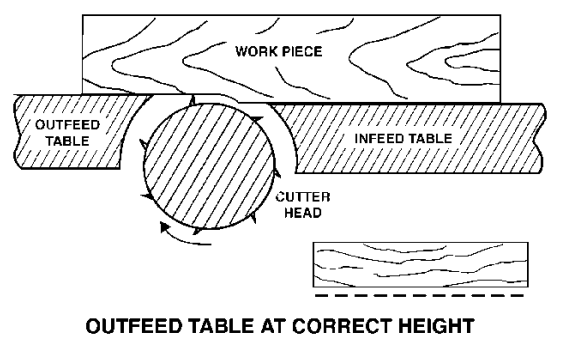

{| class=" | {| class="wikitable" | ||

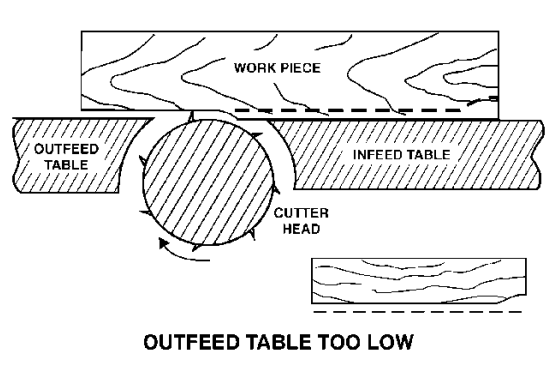

|+ Jointer Outfeed Table Height | |||

|- | |- | ||

! Too high !! Just right !! Too low | |||

! | |||

|- | |- | ||

| | | Workpiece curved on bottom || Workpiece flat on bottom || Workpiece gouged at end | ||

|- | |- | ||

| [[File:Jointer_outfeed_high.png|350px]] || [[File:Jointer_outfeed_correct.png|350px]] || [[File:Jointer_outfeed_low.png|350px]] | |||

|} | |} | ||

Latest revision as of 13:50, 11 June 2024

Link to: Wood Shop main page

| Powermatic 16" Jointer | |

|---|---|

| General Info | |

| Make | Powermatic |

| Model | PJ1696 |

| Serial | Unknown |

| Specs | |

| Manual | Jointer User Manual |

| Asylum Info | |

| Location | Wood Shop |

| Rubric | |

| Training | |

| Testing | |

| Restrictions | red |

This is a red tool. Training and tool-testing are required.

| Eye protection required! | ||

|---|---|---|

Description

A jointer has a similar architecture to a table saw. Workpieces are fed by hand on a flat table and a rotating cutter projects through the table top. Unlike a table saw, the jointer cutter is cylindrical and mills the bottom surface of the workpiece to flatten it out.

Use For

Wooden boards only

Length > 8 inches

| |

|---|---|

| The Powermatic Jointer waiting to be used |

| |

|---|---|

| WHIRLING KNIVES! |

Width > 3/4"

Wood with uneven grain requires special care.

Do Not Use For

Fiberboard

Plastics

Composites

Metals

Safety Notes

Personal:

| |

|---|---|

| Don't chop off your fingers! |

| |

|---|---|

- Eye protection required

- Hearing protection recommended

- No loose clothing or jewelry, roll up sleeves above the elbows.

- Tie up or cover long hair

- Closed-toe shoes with good traction.

Tool:

- Make sure the guards are in place and working well.

- Switch on the Dust Collector: Coral AF/2C free-standing 2-filter between the 1696 Jointer and the 201 Planer ("The Beast".)

- Keep hands at least 3 inches away from the blades at all times.

| |

|---|---|

| Shift hands during cut. MAINTAIN PRESSURE ON THE WORKPIECE. |

- Don't cut wood less than 8" long, 3/4" wide or 1/4" thick.

- For wood less than 12" long, 3" wide and 3" thick, a hold-down or push block is required

- Never apply pressure to stock directly above the cutter head. This can lead to the stock tipping into the cutter.

- Wood grain must run in the direction of the cutting.

- Never make cuts greater then 1/8" deep

- Do NOT wear gloves

Setting the Outfeed Table Height

1. Raise the outfeed to its highest point and place a straight edge across the cutter.

2. Turn the cutter head until one row of knives is at its highest point.

3. Lower the outfeed table until the straight edge contacts a knife blade. Rock the head slightly to make sure the apex of the knife is contacting the straight edge.

4. Lock the outfeed table at this setting.

| Too high | Just right | Too low |

|---|---|---|

| Workpiece curved on bottom | Workpiece flat on bottom | Workpiece gouged at end |

|

|

|