48-inch Jump Shear: Difference between revisions

From Artisans Asylum Wiki

No edit summary |

No edit summary |

||

| Line 34: | Line 34: | ||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | {| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

! colspan="2" class="infobox-image" | [[File:Metal_Shop_jump_shear_thickness_capacity.png| | ! colspan="2" class="infobox-image" | [[File:Metal_Shop_jump_shear_thickness_capacity.png|300px|thickness equivalents]] | ||

|- | |- | ||

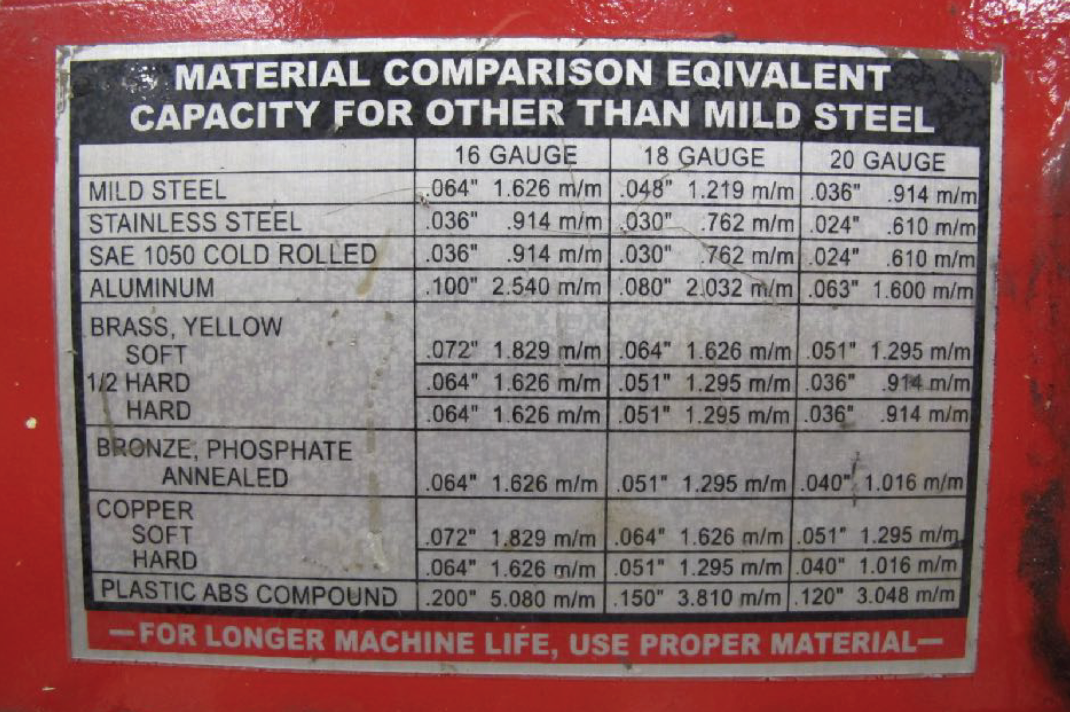

| colspan="2" | Equivalent thickness for shearing different metals relative to mild steel. | | colspan="2" | Equivalent thickness for shearing different metals relative to mild steel. | ||

| Line 49: | Line 49: | ||

==Basic Operation Instructions== | ==Basic Operation Instructions== | ||

'''Test before use - make sure blades are not interfering with each other.''' | |||

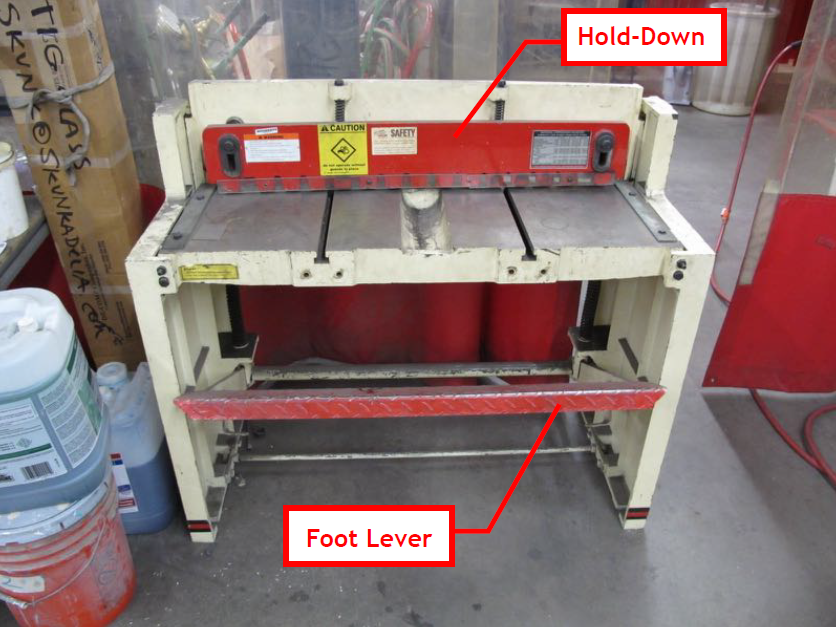

1. Step on Foot Lever | |||

2. As the foot lever travels downward, the Hold Down will press against the work piece at about half way. The Foot Lever will stop at this point. | |||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | {| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

| Line 56: | Line 62: | ||

|- | |- | ||

|} | |} | ||

3. To engage the cutting blade and perform the cut, use both feet to “jump" on the Foot Lever and press it to the floor. | 3. To engage the cutting blade and perform the cut, use both feet to “jump" on the Foot Lever and press it to the floor. | ||

Revision as of 14:18, 8 February 2024

| 48-inch Jump Shear | |

|---|---|

| General Info | |

| Make | Jet |

| Model | FS-1636N |

| Serial | Unknown |

| Specs | n/a |

| Manual | Manual |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | n/a |

| Training | Tool classes |

| Testing | Tool testing, or [[:Category:Metal Shop#Tool Testing

Night|come to the shop on Tool Testing Night]] |

| Restrictions | green |

Use for:

- Up to 16 ga (0.0625") sheet metal, any metal is okay

- Note that different metals have different thickness limits.

Do Not Use for:

- Any sheet metal exceeding max thickness

Hazard Analysis

- The workpiece can snap unexpectedly or break. Eye Protection Required

- Caught-between injuries when cutting

- Don’t pinch hands in the machine’s moving parts

- Don’t smash a foot under the foot petal

- Shin injuries from slipping off the foot pedal

- Cuts/ scrapes from sharp cut edges of work

| Eye protection required! | ||

|---|---|---|

| |

|---|---|

| Equivalent thickness for shearing different metals relative to mild steel. |

Operation Notes

- To perform multiple cuts of the same length, use the backstop and front stop attachments (stored under the pan and box brake).

- Thickness limits are different for different metals.

Refer to the chart on the machine

Basic Operation Instructions

Test before use - make sure blades are not interfering with each other.

1. Step on Foot Lever

2. As the foot lever travels downward, the Hold Down will press against the work piece at about half way. The Foot Lever will stop at this point.

| |

|---|---|

| The foot lever and hold down on the jump shear. |

3. To engage the cutting blade and perform the cut, use both feet to “jump" on the Foot Lever and press it to the floor.

Test with Craft Paper A paper grocery bag works well.

| |

|---|---|

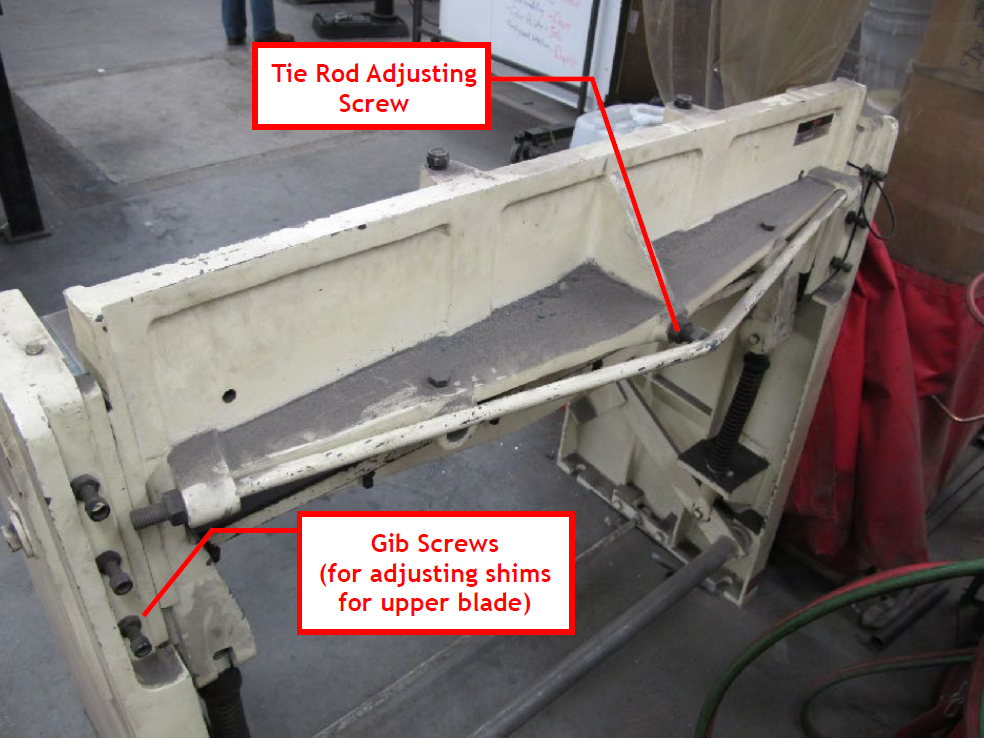

| Adjustment screws on the rear of the jump shear, for the upper blade. |

| |

|---|---|

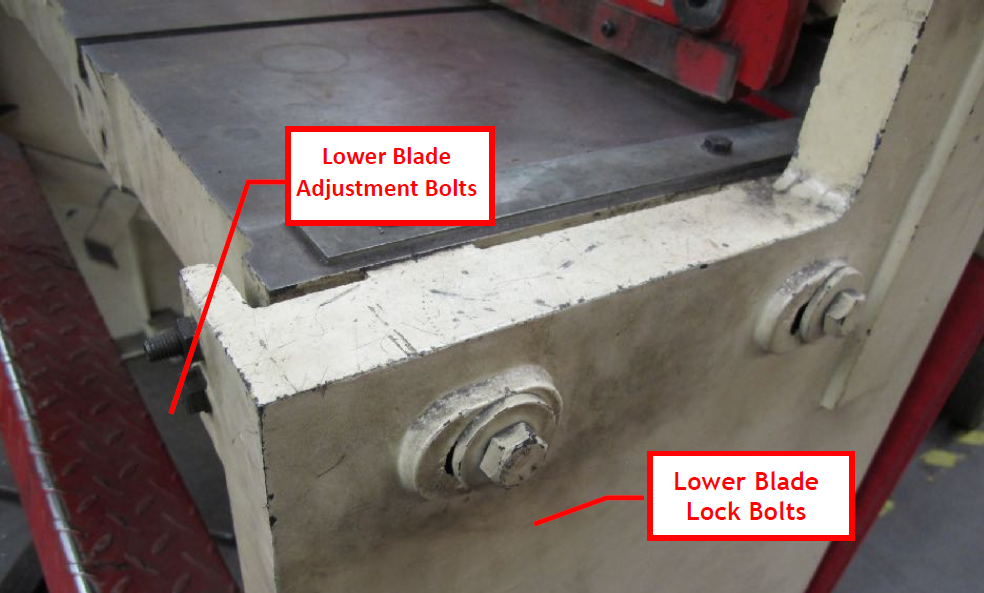

| Adjustment screws on the front and sides of the jump shear, for the lower blade. |

- If the shear cuts paper on the ends but not the center, loosen the hex nut and turn the tie-rod adjusting screw clockwise, as viewed from back, until paper is cut the entire length.

- 'If the shear cuts paper in the center but not the ends, loosen the hex nut and turn the tie-rod adjusting screw counter-clockwise until the paper is cut the entire length.

- Retighten the hex nut against the frame.

- To adjust the bottom blade, loosen the large bolts on the sides and adjust with bolts on the front.

Video

https://www.youtube.com/watch?v=S0Vl77nS_5U&t=2s Use of the jump shear]