Shop Made Benders: Difference between revisions

From Artisans Asylum Wiki

No edit summary |

No edit summary |

||

| Line 32: | Line 32: | ||

* Cuts / Scrapes / bruises if care is not taken to prevent metal stock from slipping during the bending process. | * Cuts / Scrapes / bruises if care is not taken to prevent metal stock from slipping during the bending process. | ||

{{EyeWarning}} | {{EyeWarning}} | ||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | {| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

! colspan="2" class="infobox-image" | [[File:Shop_made_benders_tools laid out.png|300px|tools laid out ]] | ! colspan="2" class="infobox-image" | [[File:Shop_made_benders_tools laid out.png|300px|tools laid out ]] | ||

Revision as of 21:19, 7 February 2024

| Shop-Made Benders | |

|---|---|

| General Info | |

| Make | You make it! |

| Model | |

| Serial | Unknown |

| Specs | n/a |

| Manual | |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | n/a |

| Training | Tool classes |

| Testing | Tool testing, or [[:Category:Metal Shop#Tool Testing

Night|come to the shop on Tool Testing Night]] |

| Restrictions | green |

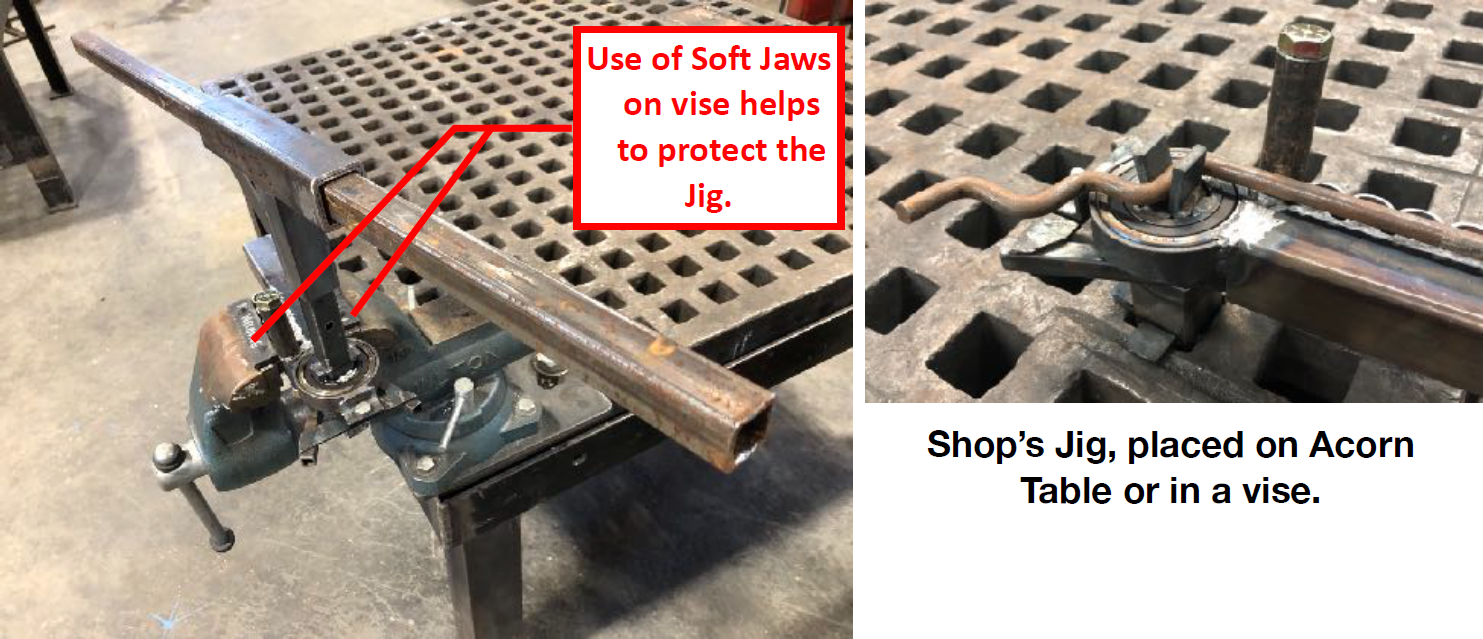

For use with shop’s the Acorn Tables and Vises

Experiment with what’s available, and feel free to add to the collection.

Use for:

- Bending rod and flat bar, capacity dependent on the jig.

- Bend curves, angles, and freeform shapes.

Do Not Use for:

- Bending welded or excessively work hardened metals.

You can try, but it may not go well!

Hazard Analysis

- Metal can snap while bending, and flakes of rust, mill scale, or paint can become airborne. Eye protection required.

- Pinched fingers, skin.

- Cuts / Scrapes from sharp cut edges of the workpiece.

- Cuts / Scrapes / bruises if care is not taken to prevent metal stock from slipping during the bending process.

| Eye protection required! | ||

|---|---|---|

| |

|---|---|

| Shop-made bending tool collection |

Operation Notes

- The Metal Shop has a collection of shop-made jigs, many inspired by YouTube videos.

- In general, watch the jig. If you see that the jig is bending (as opposed to your material bending), you’ve exceeded the jig’s capacity.

- If your material is the same size or thicker than the material used to make the jig, you run the risk of bending the jig instead of your material.

| |

|---|---|

| Use of the vise to hold a bending tool |

Videos

| |

|---|---|

| Video: Multipurpose bending tool |

The shop has a lighter duty version of this with a base that fits into the holes of the Acorn Tables.

- This Jig can also be placed in a vise. (See above)

- Free free to construct additional accessories for this jig.

| |

|---|---|

| Video: How to curl a rod |

| |

|---|---|

| Video: On Leverage |

| |

|---|---|

| Time to get creative and MAKE STUFF!!! |