Powermatic 201 22-inch Surface Planer: Difference between revisions

From Artisans Asylum Wiki

No edit summary |

No edit summary |

||

| Line 40: | Line 40: | ||

* Wood with knots, uneven or cross-grain | * Wood with knots, uneven or cross-grain | ||

* Particle board, laminates, or other composites. | |||

* Boards without a flat surface on at least one side | * Boards without a flat surface on at least one side | ||

* | * Plastics, Metals | ||

* Anything stupid. | * Anything stupid. | ||

| Line 65: | Line 67: | ||

* Keep safety guards in place at all times when the machine is in use. | * Keep safety guards in place at all times when the machine is in use. | ||

* '''Do not push the workpiece into the machine.''' | |||

* '''Do not take a depth of cut greater than 1/16 inch.''' This is one full turn on the adjustment wheel. | * '''Do not take a depth of cut greater than 1/16 inch.''' This is one full turn on the adjustment wheel. | ||

Revision as of 19:30, 17 February 2024

| The Beast | |

|---|---|

| General Info | |

| Make | Powermatic |

| Model | 201 |

| Serial | Unknown |

| Specs | |

| Manual | 201 Planer User Manual |

| Asylum Info | |

| Location | Wood Shop |

| Rubric | |

| Training | |

| Testing | |

| Restrictions | red |

This is a RED tool. Training and tool-testing are required.

| Eye protection required! | ||

|---|---|---|

Use For

- Hardwood Boards

- Lengthwise grain

- Length > 10 inches

- Thickness > 3/8"

Do Not Use For

- Pine or Fir or other pitchy wood

- Construction or reclaimed lumber

- Wood with knots, uneven or cross-grain

- Particle board, laminates, or other composites.

- Boards without a flat surface on at least one side

- Plastics, Metals

- Anything stupid.

Safety Notes

| |

|---|---|

- Wear safety goggles. Eyeglasses are NOT safety goggles.

- This machine is LOUD. Wear hearing protection.

- No loose clothing, neckties, rings, or other jewelry. Roll up sleeves. Wear shoes with good traction. Do not wear gloves.

- Switch on the dust collector before feeding stock into the machine. It is a Coral AF/2C two-filter collector shared with the Powermatic 1696 Jointer.

- Keep safety guards in place at all times when the machine is in use.

- Do not push the workpiece into the machine.

- Do not take a depth of cut greater than 1/16 inch. This is one full turn on the adjustment wheel.

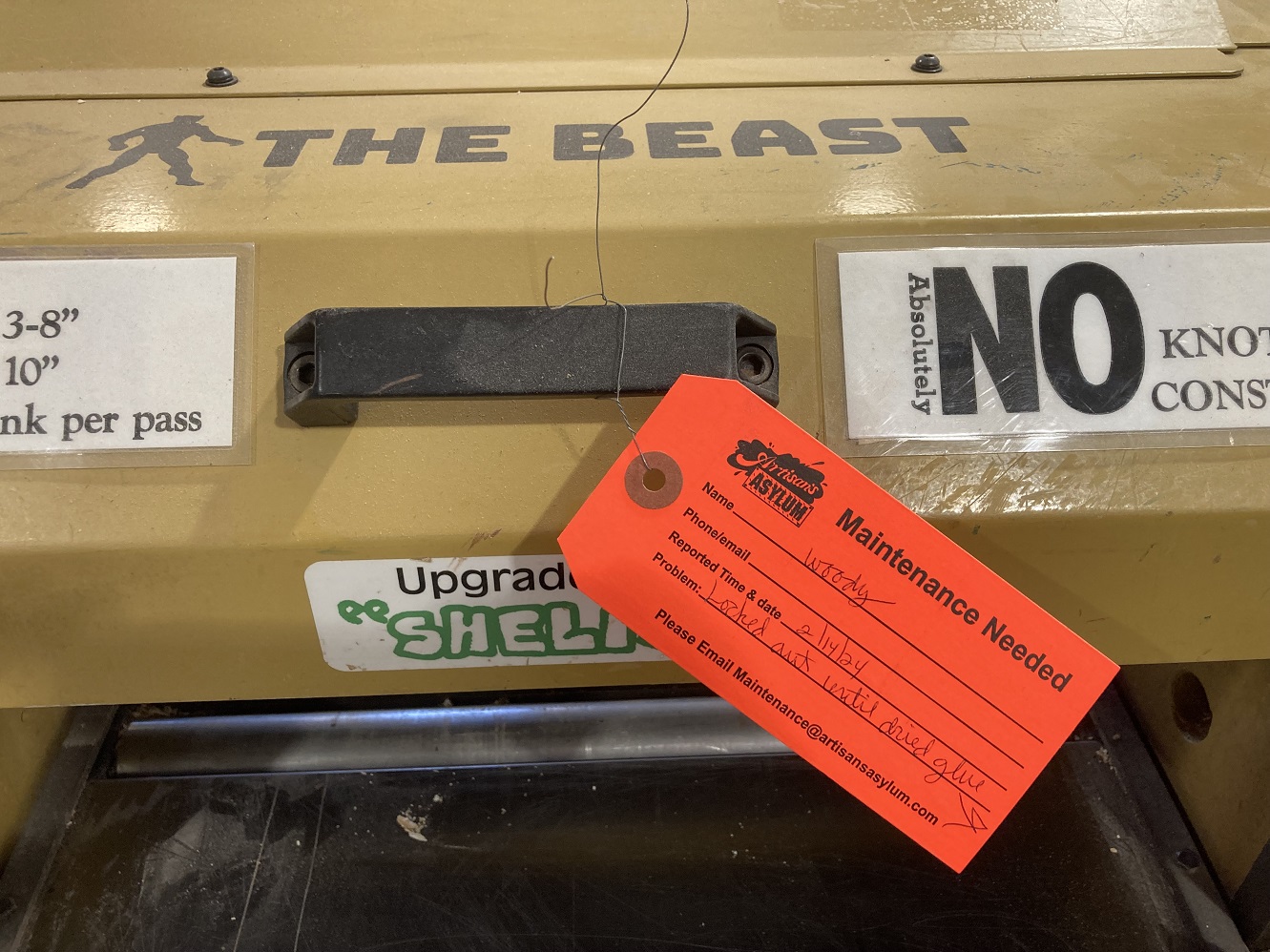

- If the machine is damaged, place a RED tag on it explaining the problem. Do not attempt to fix it yourself.

| |

|---|---|

| Maintenance Request Tag. |

- Maintain a balanced stance at all times so that you do not fall or lean against moving parts. Do not overreach or use excessive force to perform any machine operation.

- Do not feed stacked boards. They can kick back.

- Do not plane a board with loose knots or with nails or any foreign material on its surface. Twisted, warped, or wind-in stock should first be jointed on one surface before attempting to plane a parallel surface on the planer. Serious stock flaws cannot be removed by use of a planer alone.

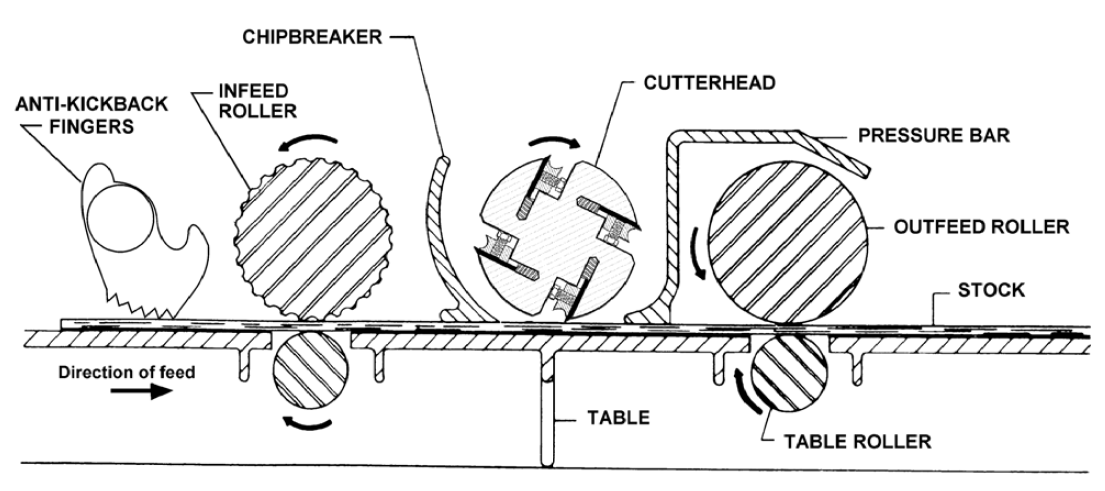

- Keep hands outside of the machine. Never reach under the guards to try to clear stock that has stopped feeding.

- When starting a cut, do not have any part of the hands under that part of the board that is over the table; the infeed roller will engage the board and force it down against the table causing a pinching action.

- Never leave the machine running unattended.

| |

|---|---|

| Cross-section of the machine. |

To interpret the results of test cuts, see pp. 16-21 of the Planer User Manual.