Flex Shaft Die Grinder

| Flex Shaft Die Grinder | |

|---|---|

| General Info | |

| Make | Foredom |

| Model | CC |

| Serial | Unknown |

| Specs | |

| Manual | |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | |

| Training | Tool classes |

| Testing | Tool testing, or [[:Category:Metal Shop#Tool Testing

Night|come to the shop on Tool Testing Night]] |

| Restrictions | green |

Use for:

- The motor has a maximum speed rating of 18,000 RPM. Always use an accessory which has the same or a higher rating than your tool.

- This flexible shaft power tool tolerates up to 12 lbs. of torque.

- The CC Series is a general, all purpose motor.

- Hand Piece accepts any size shank up to 5/32” (4mm) diameter.

Do Not Use for:

- Consider another tool for heavy duty or industrial applications. Die grinders and air tools are heavy duty alternatives.

Hazard Analysis

| |

|---|---|

- Debris, chips, and sparks can become airborne during the use of this tool. Safety glasses or face shield required.

- Mask or respirator recommended to prevent inhalation of dust particles.

- No loose clothing, jewelry, neckties, etc. Tie back long hair. Loose items can cause injury when drawn in to the tool’s rotating parts.

- Never operate an accessory at speeds above the accessory’s rated maximum speed. Serious injury can result if an accessory breaks during use.

- This tool vibrates during use. Secure the motor to its hanger or work surface to prevent it from falling.

Operation Notes

| |

|---|---|

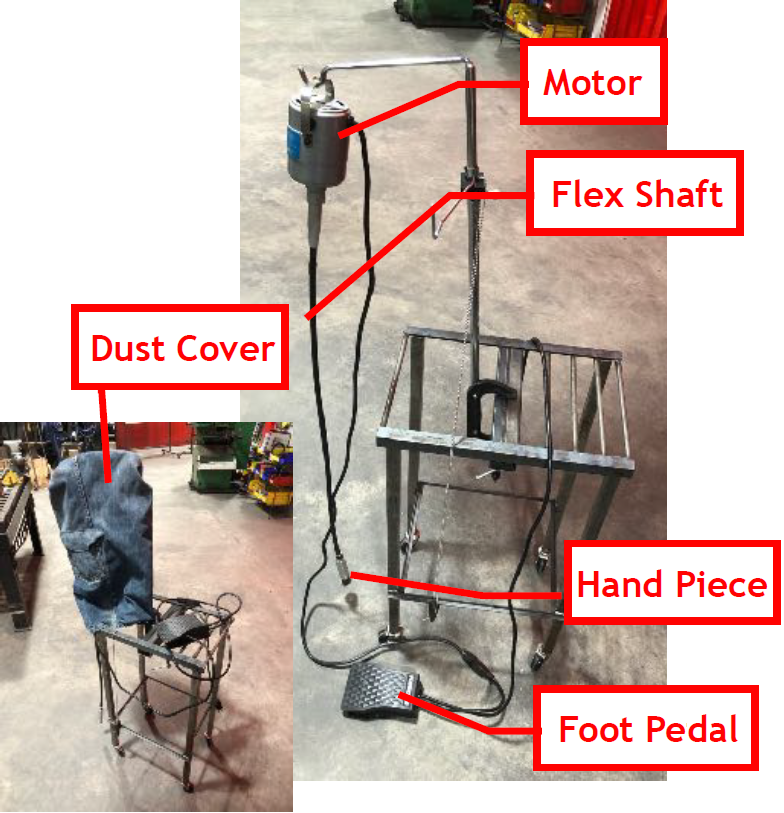

| The parts of the flex shaft. |

- The Foredom Flex Shaft as four components:

- The Motor

- The Flex Shaft (with sheath covering and inner shaft)

- The Foot Pedal (for variable speed control).

- The Hand Piece (with three jaw chuck and key).

- Let the speed of the tool do the work. Do not apply heavy pressure to the accessory.

- Generally, slower speeds are used for rougher, heavier work or when greater control over the accessory is required for precise, delicate work. Higher speeds are used for buffing, cutting and polishing.

- Always replace the dust cover when the tool is not in use. Metal dust entering the motor’s ventilation slots can shorten the tool’s life.

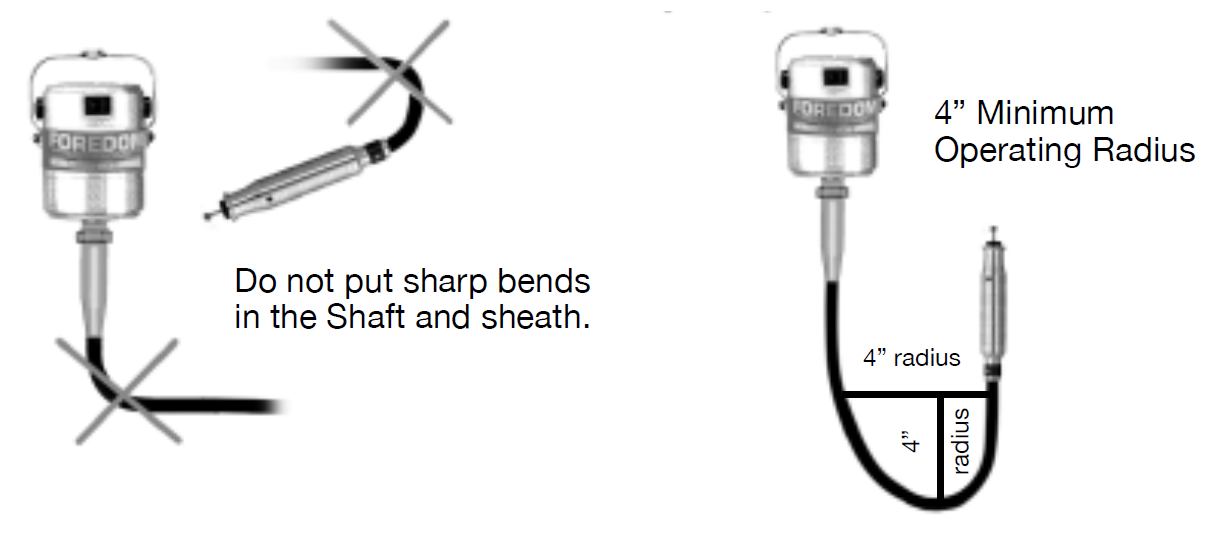

- Never put sharp bends in the Flex Shaft and its sheath. This causes excessive wear at the points of greatest friction. Maintain a 4” minimum operating radius.

Basic Operation Instructions

1. Check the accessory for damage before using it. Do not use the accessory if it is cracked, out of balance, or otherwise flawed.

| |

|---|---|

| Minimum working radius of the Flex Shaft. |

2. Insert the accessory.

- Use only accessories rated for 18,000 RPM or more.

- Open the chuck jaws using the key hanging from the flex shaft’s stand.

- Insert the shank of the accessory into the chuck as far as possible (to provide proper support.)

- Tighten the jaws with the chuck key until the accessory is secure and centered. If the accessory does not run true reopen jaws, rotate the accessory and retighten.

3. Hold the hand piece securely, then use the on/off switch to turn the motor on.

- Do not stall the motor by jamming or using excessive pressure on the accessory. This can result in damage to the motor or flexible shaft.

- Remember, this is a general use tool with an all purpose motor. Consider another tool for heavy duty or industrial applications. Die grinders and air tools are heavy duty alternatives.

4. When done, remove the accessory and replace the tool’s dust cover.

- To remove the accessory: Open chuck jaws with the key and pull the accessory out.

- Unplug the tool and place foot petal on the cart’s shelf.

Maintenance Notes

| |

|---|---|

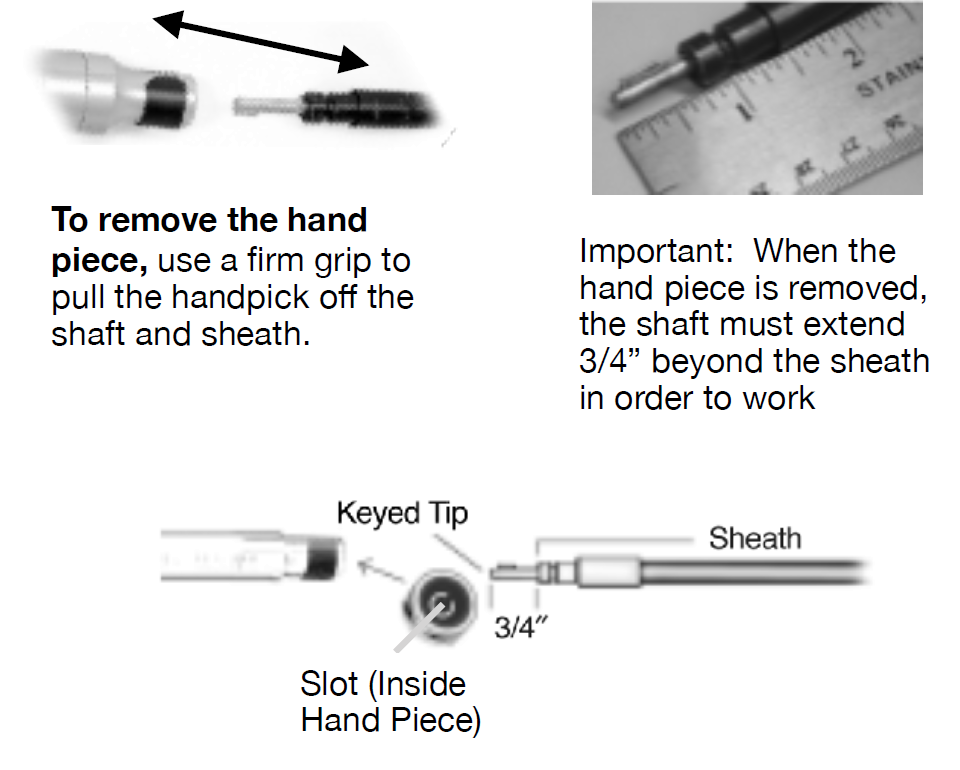

| Disassembly of the hand piece |

- Shafts and sheaths last longer when they are not used at sharp angles or loops. However, there is no way to avoid wear and tear, and under normal conditions a flexible shaft machine may require several replacement shafts and sheaths during its lifetime.

- Routine Cleaning and Lubrication of the Flexible Shaft

- The shaft should be checked, wiped clean, and re-lubricated with grease every 50 hours of use. With every 200 hours of use, the shaft should be thoroughly cleaned with solvent and lubricated. Use Foredom flex shaft grease (p/n 10006) or high quality white lubricating grease.

Maintenance Notes

- Shafts and sheaths last longer when they are not used at sharp angles or loops. However, there is no way to avoid wear and tear, and under normal conditions a flexible shaft machine may require several replacement shafts and sheaths during its lifetime.

- Routine Cleaning and Lubrication of the Flexible Shaft

- The shaft should be checked, wiped clean, and re-lubricated with grease every 50 hours of use. With every 200 hours of use, the shaft should be thoroughly cleaned with solvent and lubricated. Use Foredom flex shaft grease (p/n 10006) or high quality white lubricating grease.

- Routine Cleaning of the Motor

- Foredom Motors need air circulation through the motor housing to remove waste heat and cool the windings. Inlet and outlet slots provide the means for air flow. However, saw dust and conductive debris (like metal filings or gold dust) can enter in through these slots. If not cleaned regularly, dust could collect causing an electrical short. Therefore in high dust environments Foredom recommends cleaning the motor every 40 hours of use. To remove dirt/dust buildup, brushes should be removed, cleaned and replaced, and air should be blown through the motor.