Abrasive Blade Metal Chop Saw

Link to: Metal Shop main page

Link to: Metal Shop tool list

| Abrasive Blade Chop Saw | |

|---|---|

| General Info | |

| Make | Dewalt |

| Model | D28710 |

| Serial | Unknown |

| Specs | |

| Manual | Dewalt Chop Saw Manual |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | |

| Training | Tool classes |

| Testing | Tool testing, or come to the shop on Tool Testing Night |

| Restrictions | red |

Description

This tool is a circular saw mounted to a mechanical arm that allows it to travel smoothly in the plane of the cut. It can tilt up and down to cut a metal workpiece. The workpiece is clamped firmly against a fence in the back of the machine and the saw cuts when it is tilted down.

Superficially it resembles a wood-cutting miter saw but operates much differently. This machine has many fewer adjustments and degrees of freedom than the miter saw.

Use for:

- Hardened Steel

- Mild Steel

Do Not Use for:

- Aluminum

- Copper, Brass, Bronze

Soft metals will gum up the abrasive cutting disk.

- Zinc (or anything galvanized).

- Titanium

Hazard Analysis

| |

|---|---|

- Tool is very loud. Hearing protection required.

- Flying pieces from broken abrasive discs/ blades. Eye protection required.

- Prevent drawn-in injuries. No loose clothing or gloves.

- Cuts/ scrapes from sharp cut edges of work

- Burns from hot workpieces

- Breathing particulates thrown into the air. Respiratory protection recommended.

| Eye protection required! | ||

|---|---|---|

| |

|---|---|

| Dangerous clutter behind the Chop Saw |

Basic Operation Instructions and Best Practices

1. Before operation, perform a quick safety check:

- Never use a damaged cutting wheel — Inspect for cracks or flaws. Damaged wheels may break or shatter during saw operation.

- Remove anything from behind the saw before operating.

2. Secure work piece in the chop saw’s vise.

- Work piece must fill vise to at least center of the vise’s back fence.

- Prevent mishaps: Understand how the rotating blade will try to move your part in the vise and position / stabilize your workpiece accordingly. (See Clamping Tips below.)

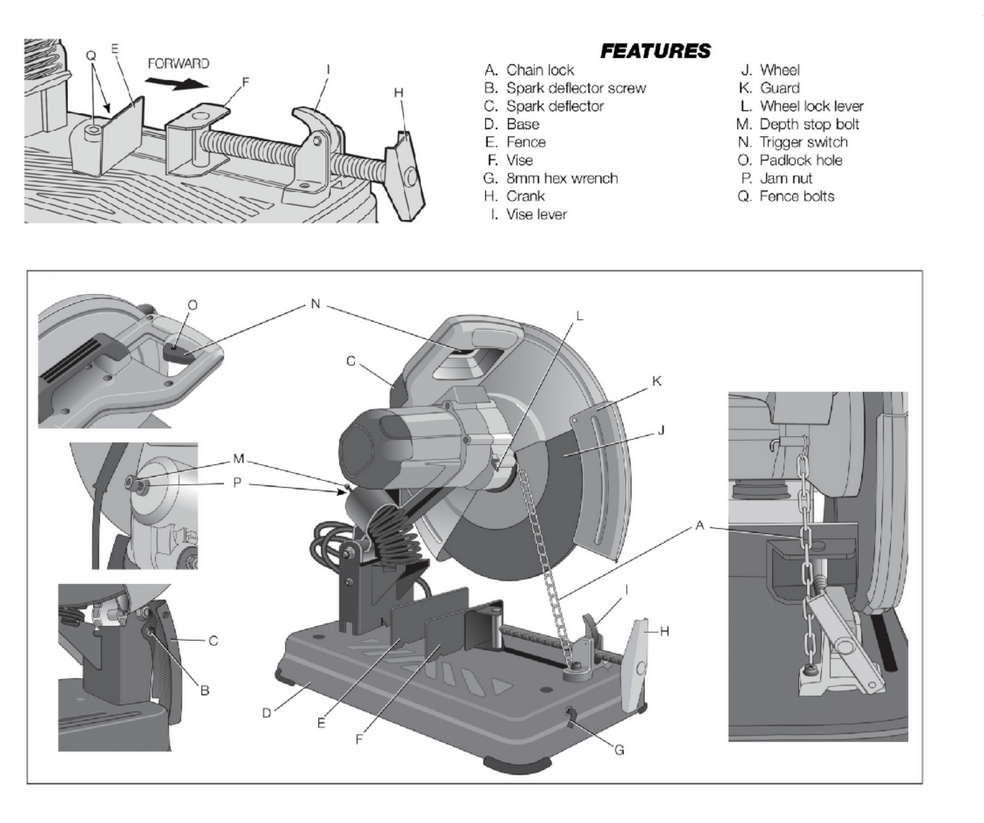

- Use the vise lever to fasten the workpiece, then tighten securely by turning the vise crank. (See features H and I.)

3. Perform the cut.

- Watch where you stand - avoid line of cutting wheel. Sparks and small pieces will tend to kick back toward wall, but can fly in any direction.

| |

|---|---|

| Chop Saw clamping tips |

- Never start with cutting wheel inserted into or touching the workpiece. Press handle trigger to start the blade, then lower the blade.

- Vary force and travel speed to match the shape of work – judge by ear and by the sparks produced. No quick chops.

Clamping Tips

Be aware of blade rotation.

Angles are best cut with both legs facing down. This allows a safe cut, but is not optimal for miter cuts.

Another option for Angles: L facing backward, into the rotation of the blade.

Use square tube as a stabilizer. A spacer block slightly more narrow than the work piece can increase blade utilization.

Long workpieces must be supported to remain level. The cut-off end should be free to fall in order to avoid wheel binding.

| |

|---|---|

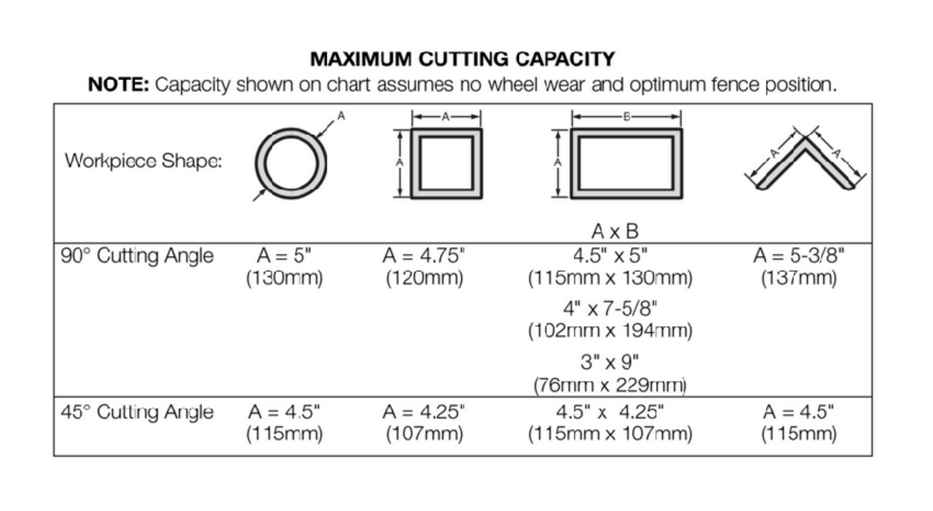

| Stock size limits for the Chop Saw |

| |

|---|---|

| The parts of the Chop Saw |