PowerMax 30XP Handheld Plasma Cutter

Link to: Metal Shop main page

Link to: Metal Shop tool list

| Eye protection required! | ||

|---|---|---|

| Handheld Plasma Cutter | |

|---|---|

| General Info | |

| Make | Hypertherm |

| Model | PowerMax 30XP |

| Serial | |

| Specs | n/a |

| Manual | PowerMax 30XP Manual |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | n/a |

| Training | |

| Testing | |

| Restrictions | red |

Description

Similar to an arc welder, a strong electric current is passed between an electrode and the workpiece. A conductive plasma forms in the gap between the two electrodes, reaching a temperature around 15,000 Kelvin (~25,000° F)

In a plasma cutter the arc is combined with a jet of air. The air jet clears molten metal from the workpiece, allowing the machine to make deep cuts in metal sheets. In some metals, especially steel, the air also contributes heat by oxidizing the metal under the arc.

Use For:

Cutting, piercing, or gouging metals

Mild or Hard steel

Stainless steel

Copper and alloys

Aluminum

Titanium

Cutting thickness up to 5/8 inch (16mm)

Piercing thickness up to 1/4 inch (6mm)

Do Not Use For:

Toxic metals (Lead, Zinc, etc)

Galvanized steel

Non-metals

Flammable materials

Safety Notes

- Plasma radiation and UV can damage eyesight. Shade 5 eye protection or darker required.

- Wear welding gloves, face protection, cotton clothing (no synthetics) and closed toe shoes.

- Ear protection recommended.

- Toxic fumes may be emitted, especially from chromium-containing alloys such as stainless steel and tool steels. Wear a respirator in those cases.

- Arc ignites immediately when torch trigger is pushed.

- It cuts quickly through gloves and skin. - Keep hands, clothes, and objects away from the torch tip. - Keep hands clear of the cutting path. - Never hold the workpiece. - Never point the torch toward yourself or others.

* Various safety links to keep you awake at night:

ANSI - General Safety in Welding and Cutting

Best Practices

| |

|---|---|

- A hard-copy of the Operator's Manual is stored in the carrying case.

- ALWAYS WEAR EYE PROTECTION! It is mandatory in the Metal Shop, even if you aren't doing anything but looking around.

- For the plasma cutter, wear Shade 5 goggles or better. The requirement is similar to that for the Oxy-Acetylene Torch.

- Instant-On Torch. Before plugging in, make sure the power switch is in the OFF (O) position. Hand Torch safety catch reduces accidental firing.

- Remove flammable objects and liquids from the work area.

- Note fire extinguisher location and use.

- Do not use a drum or other closed container as a cutting table.

Machine Set-Up

In general this device is pretty easy to use.

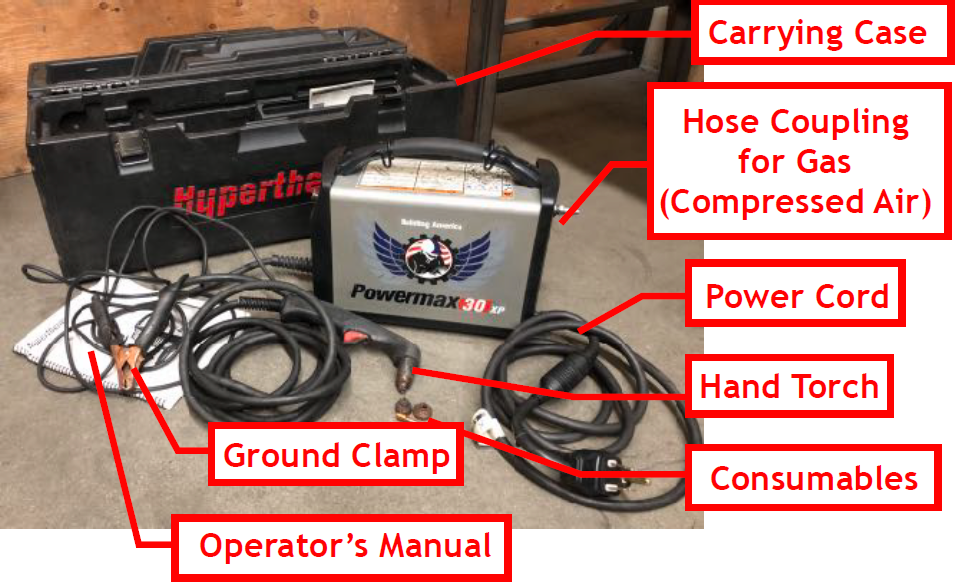

Unpacking

| |

|---|---|

| The power supply only fits one way. |

| |

|---|---|

| Someone spent a lot of time designing this compact carrying case. |

Perhaps the most difficult part is unpacking the plasma cutter from the carrying case and replacing it when finished. The cables are coiled very tightly in the left side of the case and the power supply seats on the right.

Note the asymmetry in the recesses at the bottom of the case. The power supply only fits one way back into the case, with the faceplate pointing towards the coils of cables. If you try to fit it in the wrong way around you won't be able to latch the box top, and then you won't be able to carry it using the handle.

Connections

| |

|---|---|

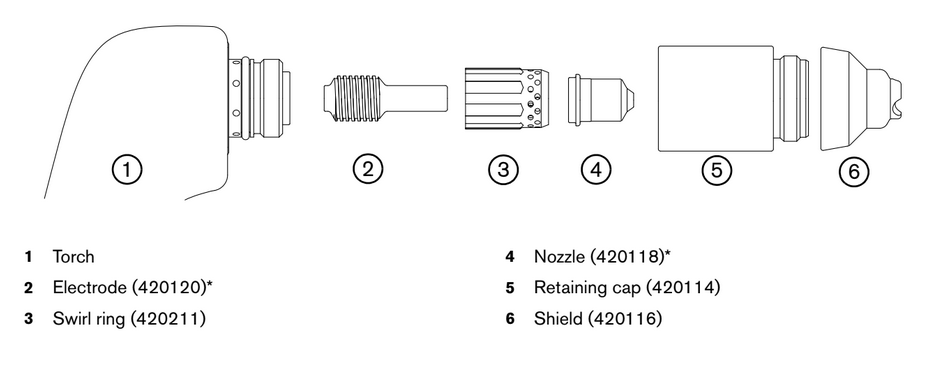

| Parts in the plasma cutter nozzle assembly. |

1. Before operation, perform a quick safety check.

- Check for damaged parts.

- Check that an appropriate, properly-matched consumable set is installed on the torch head.

- Check that the retaining cap isn't torn or frayed. There is a severe shock hazard if the nozzle becomes exposed.

2. Plug it in.

This machine has a 240 V cord that fits the same outlets as the arc welders.

| |

|---|---|

| View of the back of the power supply. |

3. Supply the machine with compressed air.

- Make sure the air compressor is turned on. The compressor is located in a closet adjacent to the Antwerp loading dock entry. Follow the instructions on the poster stuck to the compressor.

- Compressed air for the Metal Shop is presently supplied from a corner next to the entry to the Powder Coating facility. A long air hose should be coiled up and available there. The air pressure is usually around 100 psi.

- The nipple for attaching the air hose is located on the back of the power supply box, next to the power switch.

4. Attach the ground clamp to a part of the workpiece that won't get cut off.

Avoid slashing the acorn tables or the welding benches with the plasma cutter. Support the workpiece with some airspace beneath the region where you intend to cut.

Power it up

| |

|---|---|

| The front panel of the plasma cutter, showing its yellow error light for no air supply. |

Turn on the power switch on the back panel of the supply.

Use the knob on the front to set the amperage.

Check the front panel lights for an error condition. Only the green light on the right should be lit.