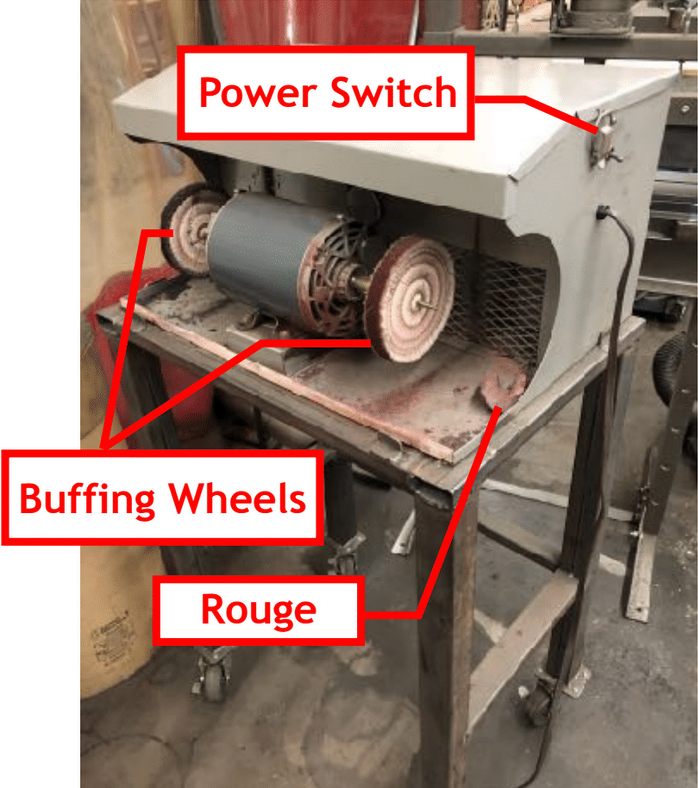

Buffing Machine

| Buffing Machine | |

|---|---|

| General Info | |

| Make | |

| Model | |

| Serial | Unknown |

| Specs | |

| Manual | |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | |

| Training | Tool classes |

| Testing | Tool testing, or [[:Category:Metal Shop#Tool Testing

Night|come to the shop on Tool Testing Night]] |

| Restrictions | green |

Use for:

- Buffing / Polishing Metal

Do Not Use for:

- Do not attach cutting wheels, wire wheels, or other unintended accessories on this buffer.

Hazard Analysis

- Prevent drawn-in injuries. No gloves. No loose clothing or jewelry.Tie long hair back.

- Flying debris / metal pieces if workpiece slips and/or breaks. Eye protection required.

- Cuts/ scrapes from sharp edges of work, or from tool misuse.

Basic Operation Instructions and Best Practices

1. Perform a quick safety check:

- Are the buffing wheels secure?

- Is the work area free of debris or other obstructions?

- Avoid unintentional starts. If the unit is unplugged, flip the power switch is to “OFF” prior to plugging in.

2. Only use buffing wheels suitable for buffing. Buffing wheels available have been supplied by other shop users. Feel free to use your own buffing wheels.

3. Buffing Compound (Rouge) may be applied to buffing wheels.

4. To avoid injury from flying objects / debris, feed work into the lower front quarter of the buffing wheel,where the wheel’s rotation sends debris away from the user.

5. Excessive workpiece pressure may slow down the action of the Buffing Wheel and/ or cause uneven marks on the workpiece. Let the tool do the work.

6. When finished, remove workpiece and flip the Power Switch to “OFF.”

7. Replace dust cover to prevent the shop’s metal dust from settling on the Buffing Wheels. The cover’s front and back are labeled with Sharpies.