Category:Drill Presses

| Drill Press | |

|---|---|

| General Info | |

| Make | various |

| Model | |

| Serial | |

| Specs | |

| Manual | |

| Asylum Info | |

| Location | Wood Shop |

| Rubric | |

| Training | |

| Testing | |

| Restrictions | red |

Description

A drill press is a free-standing power tool with a vertical sliding spindle that carries a chuck for drilling. The spindle, or "quill" is moved up and down manually by a wheel or handle to the side. The workpiece is supported by a horizontal table with adjustable height. Workpieces are clamped down to the table or held in a vise while they are drilled to varying diameters, generally ranging from 1/16" up to 3/4".

Use For (Depending on Location)

Wood

Metal

Plastic

Composites

Graphite

Regular and irregular shapes (as long as they can be clamped down)

Do Not Use For

Thin sheets

Parts too big to be lifted onto the table

Ceramics or other abrasive materials

Material that is unsuitable to the shop where the tool is located.

Machines at AA

| |

|---|---|

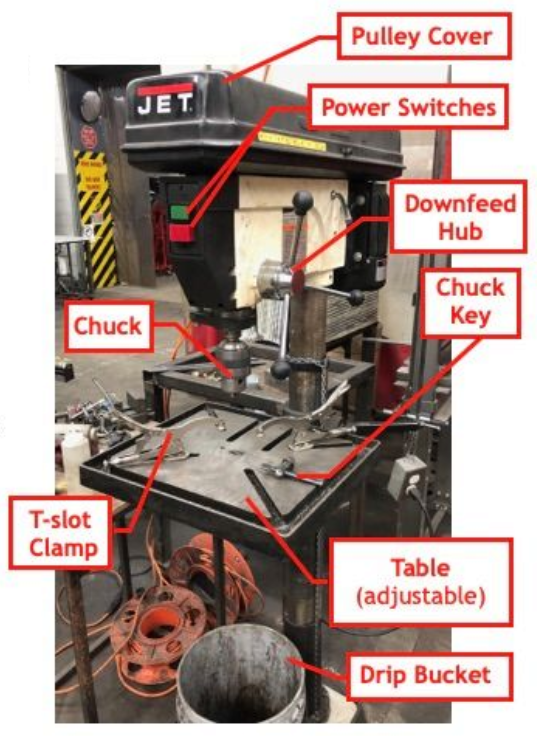

| Parts of a Drill Press |

Artisans Asylum has nine drill presses distributed in various shops around the Antwerp St. building:

- Wood Shop: 4

- Rikon 30-250

- Delta 11-990

- Delta 17-965

- Dayton 3Z918D

- Metal Shop: 2

- Dake SGB-32V

- Morgan MD-80A

- Machine Shop: 2

- Dake SGB-32V

- Walker-Turner (antique)

- Bike Shop: 1

- "SKUL DP02" (antique Delta, ca. 1940)

Parts of a Drill Press

Drive

Drill-presses are invariably belt-driven, with a motor in the back. Speeds can be changed by moving the belt from one step to another on the multiple-step pulleys. The belt and pulley system poses a severe hazard to the user if the belt cover isn't in place.

Spindle and Chuck

The spindle is a spline shaft geared to the quill handle. The pulley at the top is able to rotate the spindle while the handle is free to raise and lower the chuck for drilling. The quill handle can also be locked in place, usually with a rotating handle.

The most common chuck is the "Jacobs" style, with three jaws and a characteristic chuck key with gear teeth on its nose. This is designed to hold a drill bit (or other rotary tool) on-center with a minimum of wobble during drilling. DO NOT USE A DRILL PRESS FOR SIDE-MILLING! The chuck and spindle aren't designed to handle the lateral forces and these can ruin the machine's accuracy for other users.

Table

The table is usually horizontal, though some drill presses allow for the table to be tilted. The height is adjustable, sometimes with a crank, and sometimes with a simple clamp. When the table is simply clamped to the vertical post, care must be taken to support the weight of the table when the handle is loosened.

The table usually has slots or key-ways for attaching clamps or vises to hold the workpiece in place. Drilling a workpiece that isn't clamped down is very risky: The drill can jam in the hole during the drilling and the workpiece can start whirling around. This is particularly dangerous with thin sheets or parts with sharp edges.

Base and Post

The tool is free-standing, either on the floor or on a bench-top. The base is usually a heavy iron casting and the post is ground steel to support the clamping of the table mechanism.

For safety, it is recommended that drill presses be bolted down at the base (either to the floor or bench-top.) As of this writing, NONE of the drill presses at Artisans Asylum are bolted down. Accordingly, users must be cautious about the tool tipping over and crashing to the floor.

Tools to Use on a Drill Press

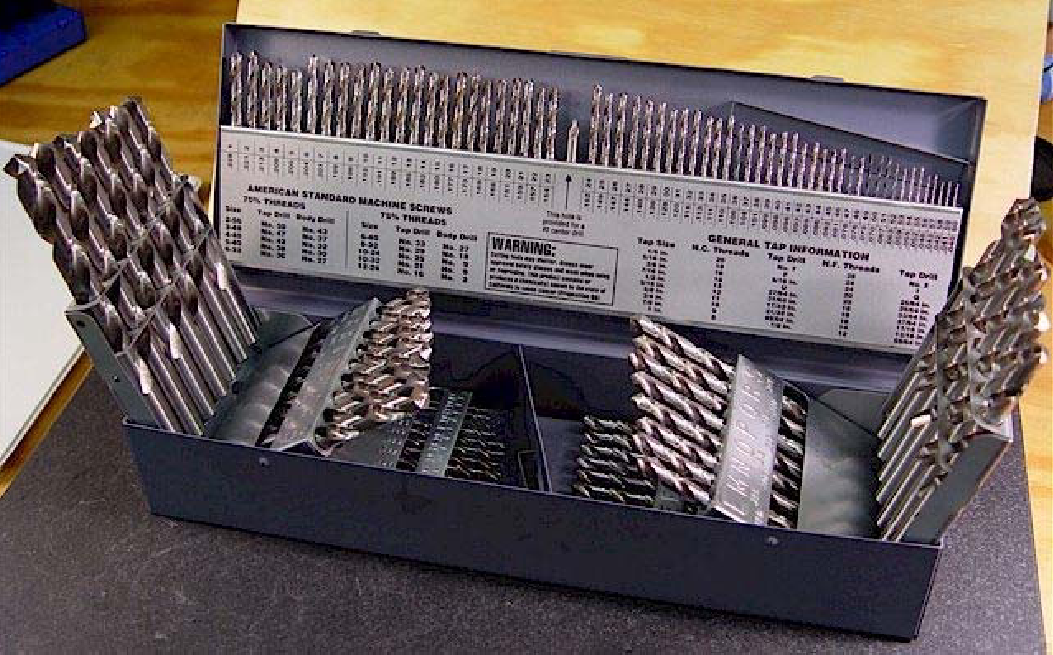

Twist Drills

This is by far the most common drill bit. Though they are designed for cutting metals, they can cut a wide variety of materials, including wood. Certain plastics can be problematic, and there are specially ground analogs to these drills especially for plastics.

| |

|---|---|

| A set of twist drills. |

| |

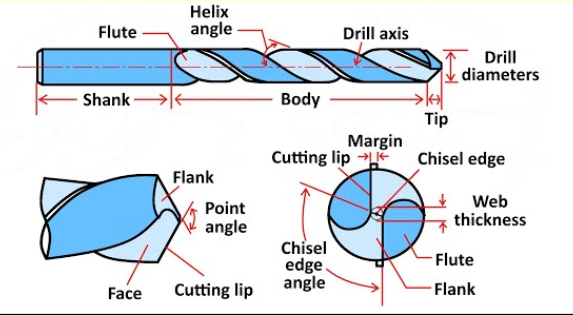

|---|---|

| Important dimensions on a twist drill |

Pages in category "Drill Presses"

The following 7 pages are in this category, out of 7 total.