Category:Vertical Band Saws -- Wood Cutting

| Wood Cutting Band Saw | |

|---|---|

| General Info | |

| Make | |

| Model | |

| Serial | |

| Specs | |

| Manual | |

| Asylum Info | |

| Location | [[:Category:|]] |

| Rubric | |

| Training | |

| Testing | |

| Restrictions | |

[[Category:]]

There are two tools in the Wood Shop in this category:

User Manuals:

Link to: Powermatic PM1500 Manual

Link to: Powermatic PWBS-14 Manual

Description

The cutting blade in a band saw is a continuous loop that travels through the machine on pulleys. In a vertical band saw, the blade travels vertically through a slot in a table, and workpieces are hand-fed through the blade to make a cut.

Wood-grain affects the forces and motions during cutting in a saw, so there is a ripping fence and a miter gauge as in a table saw. With metal cutting, the workpiece is usually clamped in a vise.

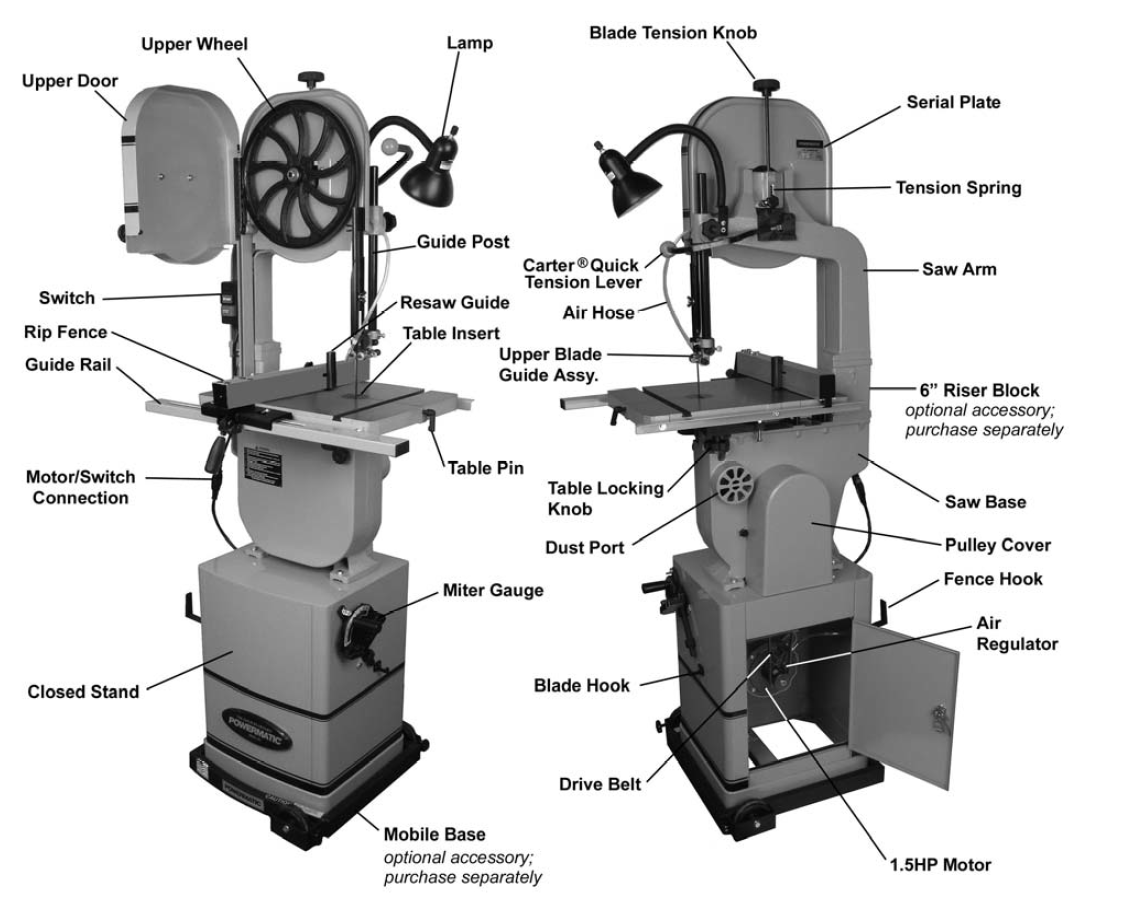

| |

|---|---|

| Parts of a typical band saw. |

Use For

- Dry, flat lumber

- Boards

- Plywood sheets that fit within the tool width

- Logs, carvings, or other irregular lumber if supported properly

- Making curved cuts (within the tolerance of the blade, see below)

Do Not Use For

- Pressure-treated

- Wet lumber

- Plastic

- Metal or metal-coated

- Composites

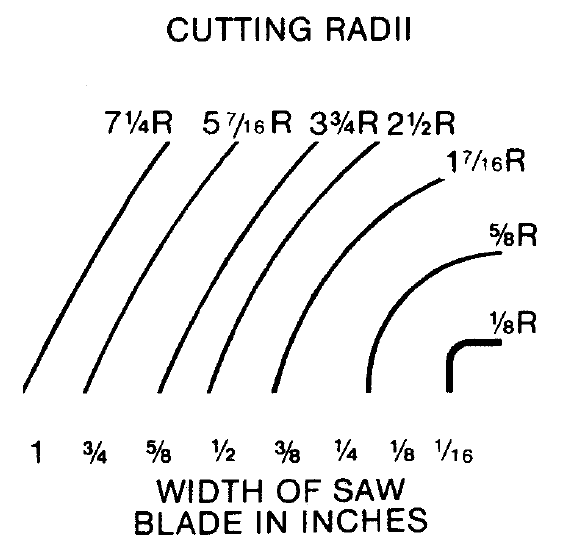

| |

|---|---|

| Cutting radii with various width of blade. |

Safety Notes

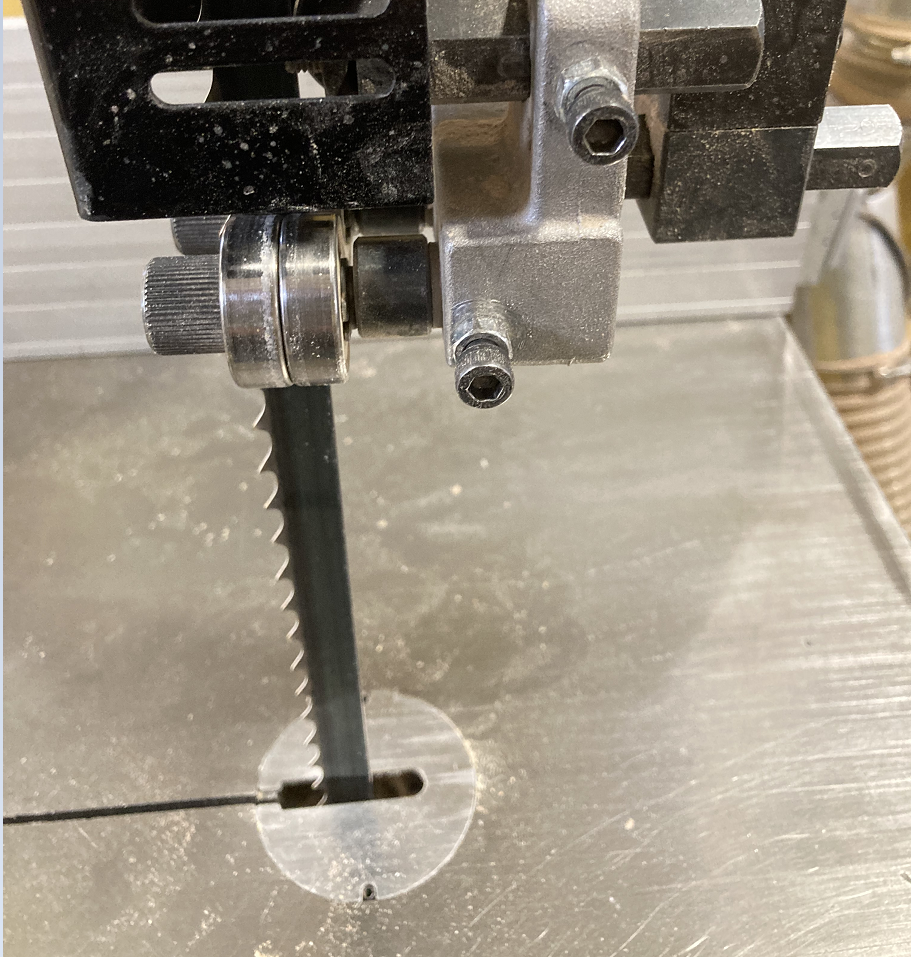

| |

|---|---|

WARNING:This is a convenient and familiar tool that can deceive the user into being casual with its operation.

Do not relax safety protocols or or treat this tool as anything but a potentially lethal hazard.

|

Eye and lung protection required! | |

|---|---|---|

| |

|---|---|

| Keep fingers away! |

Personal:

- Always wear safety glasses. Eyeglasses are not safety glasses.

- No loose clothing. Tie up long hair. No jewelry.

- Wear non-slip shoes and keep a stable stance to avoid falling or leaning against the blade.

- Do not wear gloves. Gloves can be drawn in by the moving blade, causing very serious injury.

- Hearing protection is recommended.

- Always use the dust collector. Both band saws in the Wood Shop are connected to the central dust collector (Coral AF/4C)

| Dust collection required! | ||

|---|---|---|

- All forms of dust are hazardous. Wear a dust mask to avoid exposure.

- Do not cut hazardous materials such as pressure-treated lumber.

Tool:

- Always lower the blade guard to the lowest point that will allow a cut.

- Always unplug the tool before servicing.

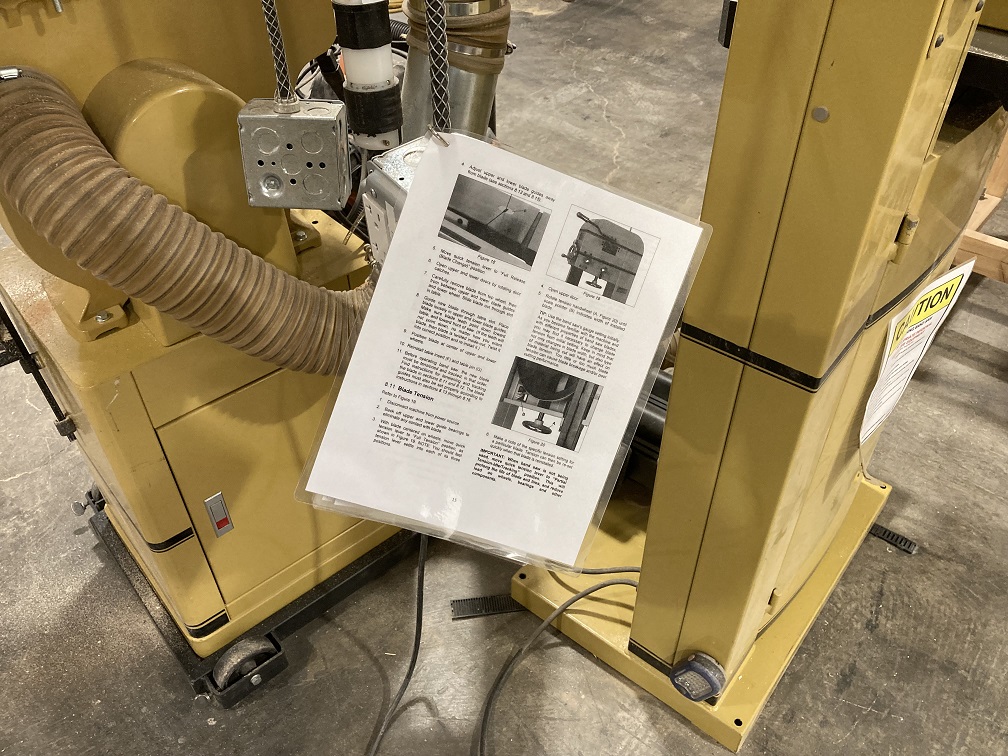

| |

|---|---|

| Laminated pages from the user's manual hanging between the two saws in the Wood Shop. |

- Remove adjusting keys and wrenches before switching on the tool.

- Keep safety guards in place at all times.

- Use a push stick when feeding small pieces into the saw.

- If the blade jams during cutting, switch off the power and allow the machine to come to a complete stop.

- If the blade comes off the drive pulleys, refer to the equipment manual for the particular unit for instructions on how to re-seat it and set the tension.

Laminated copies of the relevant pages in the user's manual are hung from a power drop between the two saws in the Wood Shop.

- Blade tensioning is generally done with a handle or a crank located underneath the idler wheel on the top. Tension force depends on the width of the blade.

Accessories

| |

|---|---|

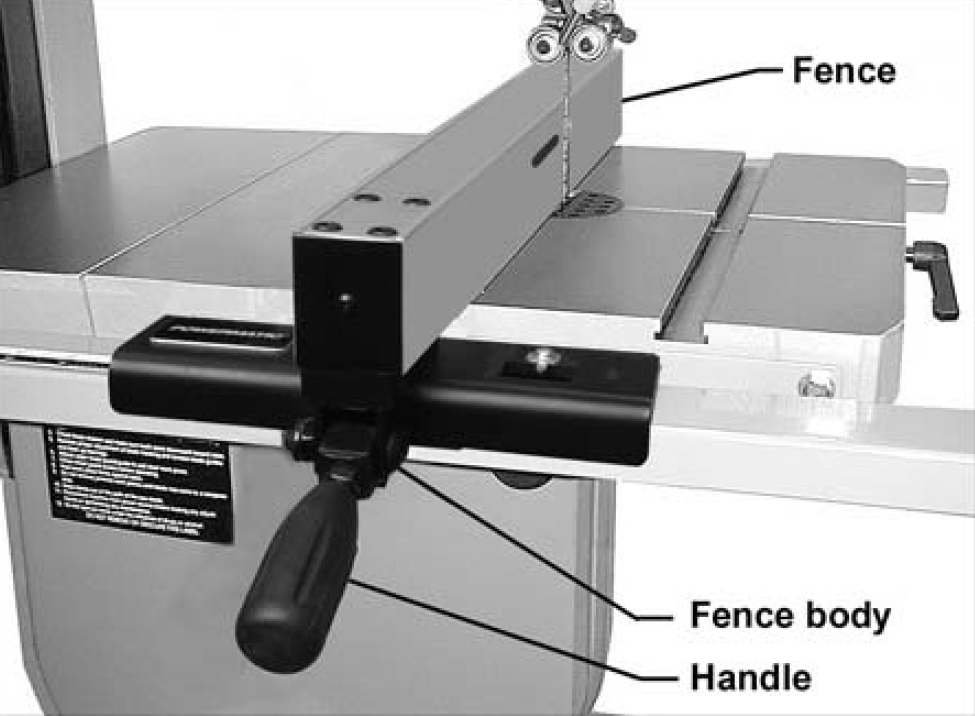

| A generic rip fence. Fences on saws in the Wood Shop may have a different profile. |

Wood-cutting band saws have a different set of accessories from metal-cutting band saws.

Rip Fence

Wood-cutting band saws have similar accessories to those on a table saw. The most important is the rip fence.

This accessory guides the workpiece lengthwise at a fixed distance through the blade. It clamps in place using the handle shown.

Note: The PM1500 saw in the Wood Shop "Bullwinkle" has an aluminum attachment to its rip fence.

Important Use a push stick to finish cuts. Keep hands and fingers away from the blade at all times.

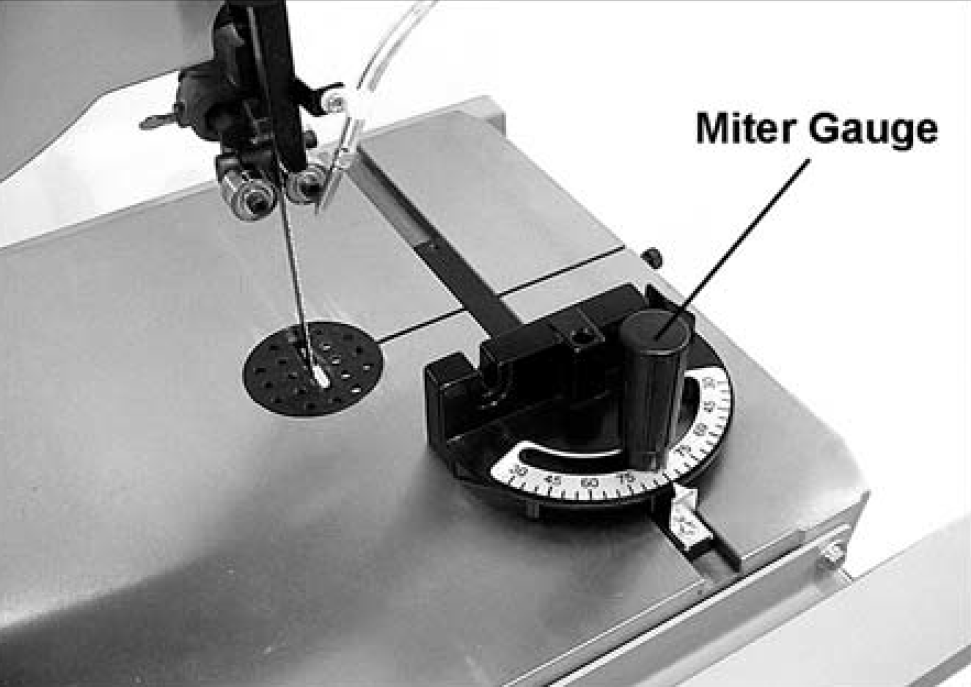

Miter Gauge

| |

|---|---|

| A generic miter gauge. |

A miter gauge is used for cross-cutting or for making miter cuts. To use it, remove the rip fence and seat the gauge in the slot on the table.

This accessory has an adjustable angle that may be set to achieve miter cuts as small as 30 degrees with respect to the feed direction.

Never cross the hands over the line of the cut when feeding a workpiece into the saw.

Always keep the blade guard down as far as possible.

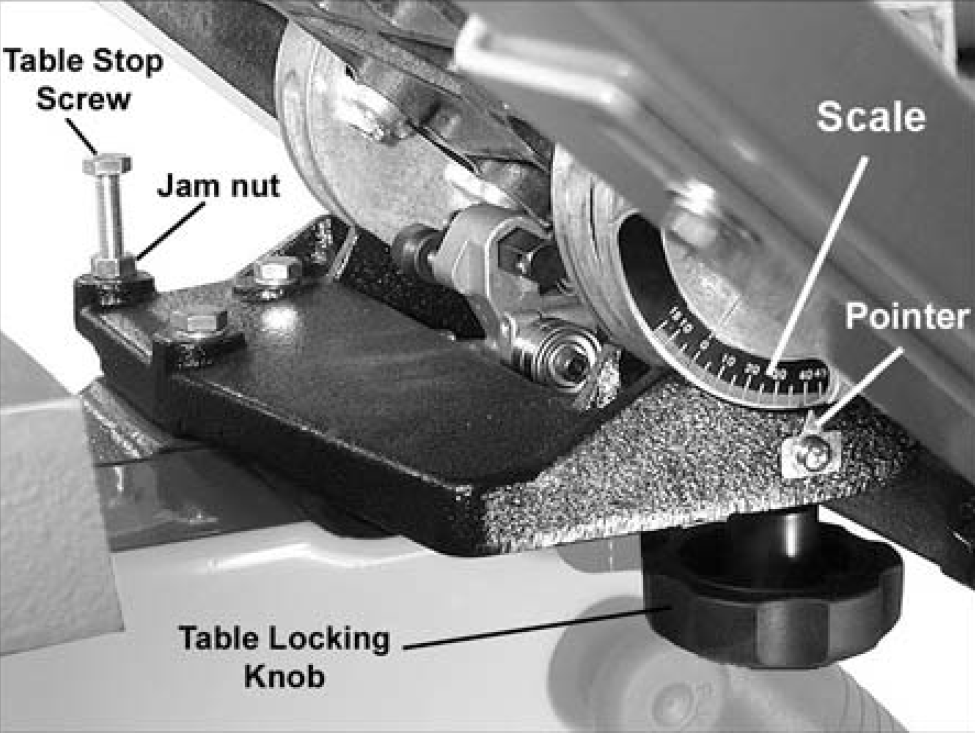

Tilting the table

Many band saws have a feature allowing the operator to tilt the table to make bevel cuts. Please check with the shop lead whether these types of cuts are allowed on a particular tool.

| |

|---|---|

| Underneath the table there may be a tilting gauge for bevel cuts. |

Pages in category "Vertical Band Saws -- Wood Cutting"

The following 2 pages are in this category, out of 2 total.