Brackets Tutorial 2a: Reverse-Engineering a Bracket in Solidworks

Link to: Bracketage Main Page

Solidworks tutorial by Jim Bredt 20240609

Introduction

This tutorial assumes basic experience with Solidworks. If you are unsure how to use the basic tools in Solidworks, then step through the first tutorial which assumes no prior experience.

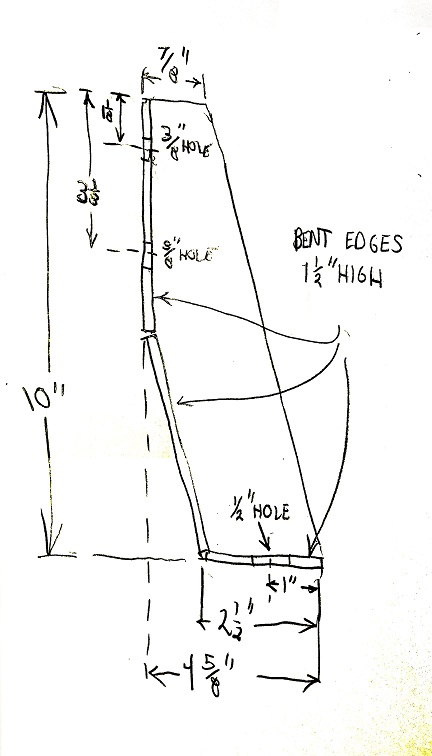

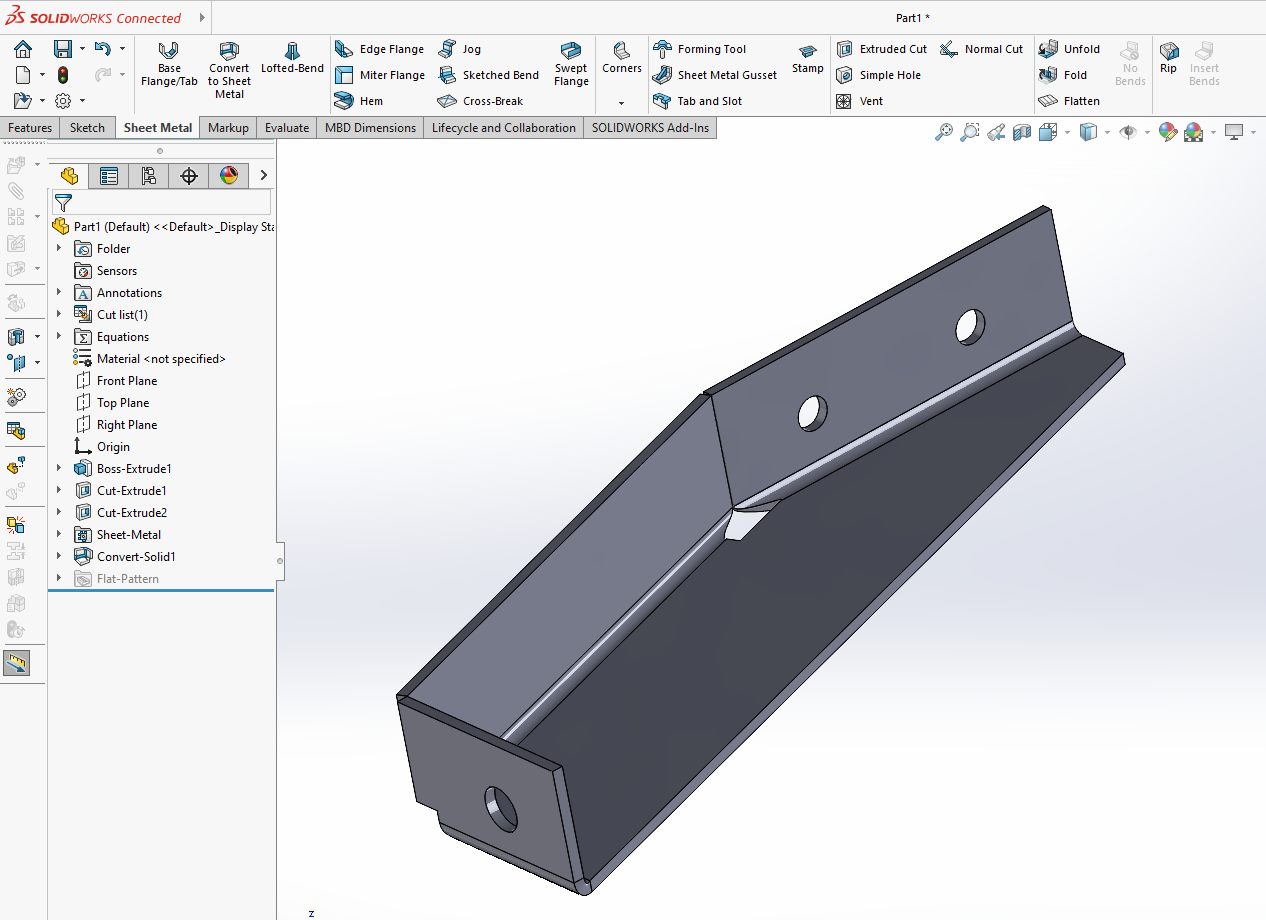

In this tutorial we will create a Solidworks design for an existing steel bracket, shown below. It is a corner brace from a modular(80/20) metal frame.

In the following section (Tutorial 2b) we will export the Solidworks data to a CNC plasma cutter and fabricate a duplicate.

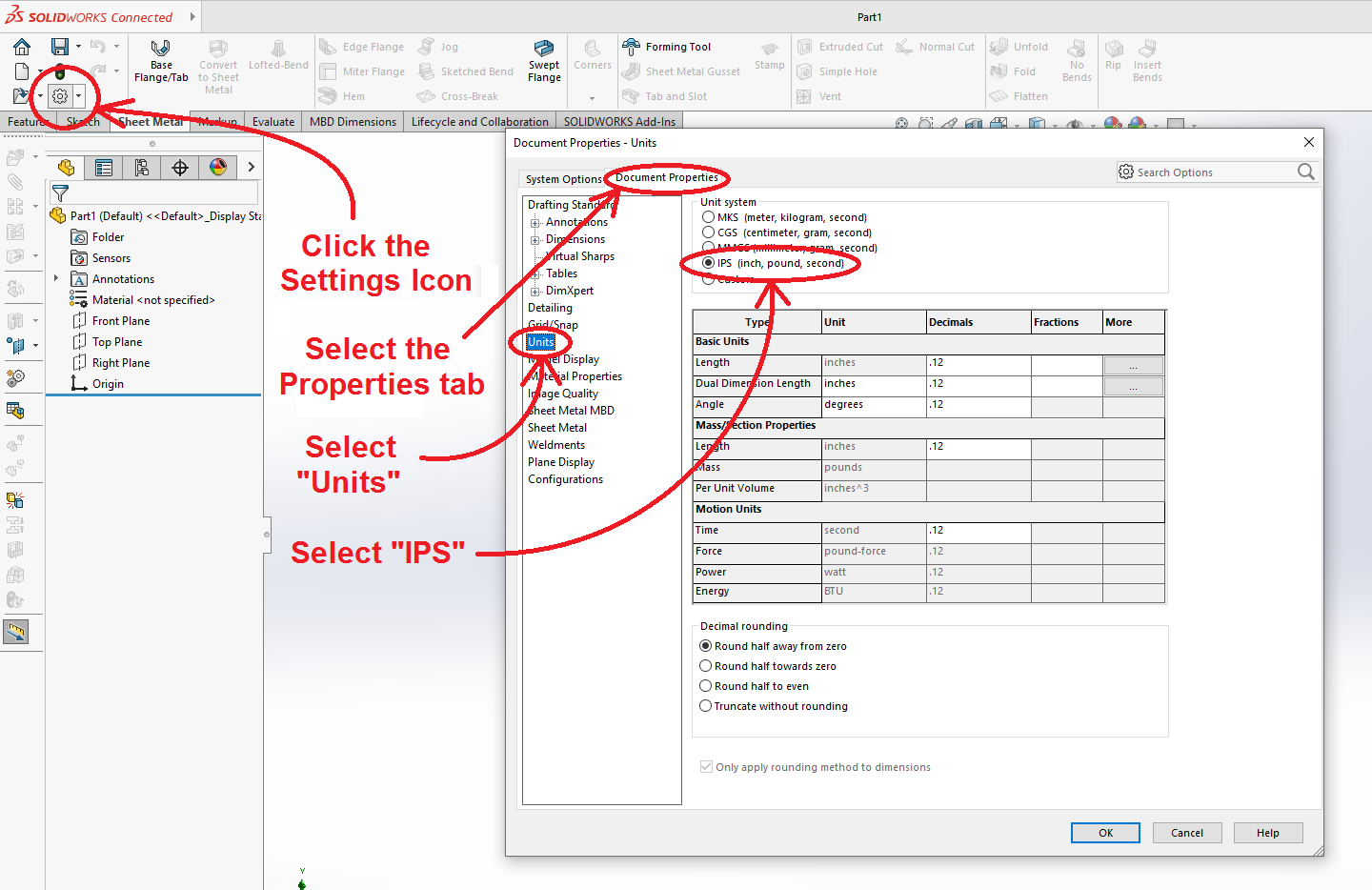

Change the Units to IPS

Change the drawing units to inches. Click on the (![]() ) gear icon in the upper left corner of the window. Select the "Document Properties" tab. Make sure the units are set to "IPS" (Inches-Pounds_Seconds). The reason for this is we will be creating data for the Torchmate CNC plasma cutter, and that machine operates in inch units.

) gear icon in the upper left corner of the window. Select the "Document Properties" tab. Make sure the units are set to "IPS" (Inches-Pounds_Seconds). The reason for this is we will be creating data for the Torchmate CNC plasma cutter, and that machine operates in inch units.

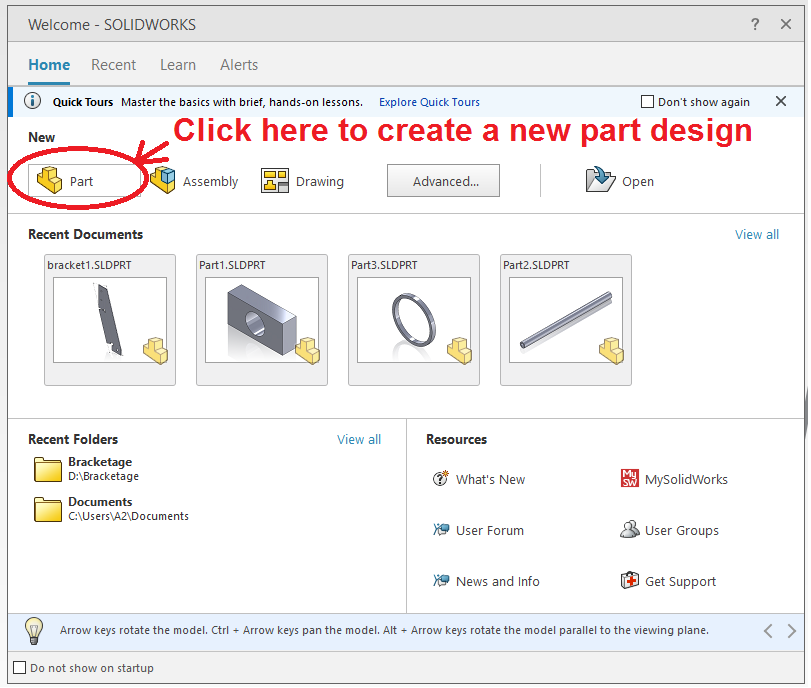

When you load Solidworks you will see a dialog box like the one below.

Select "Part" to create a new design for a part.

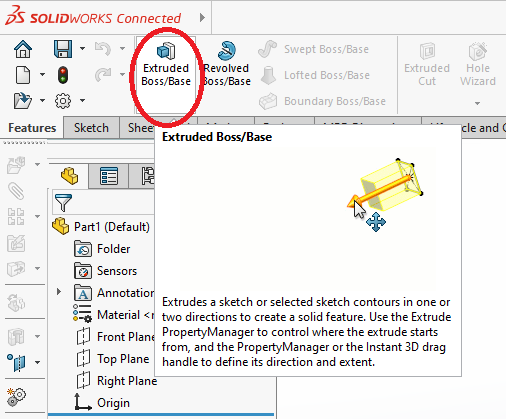

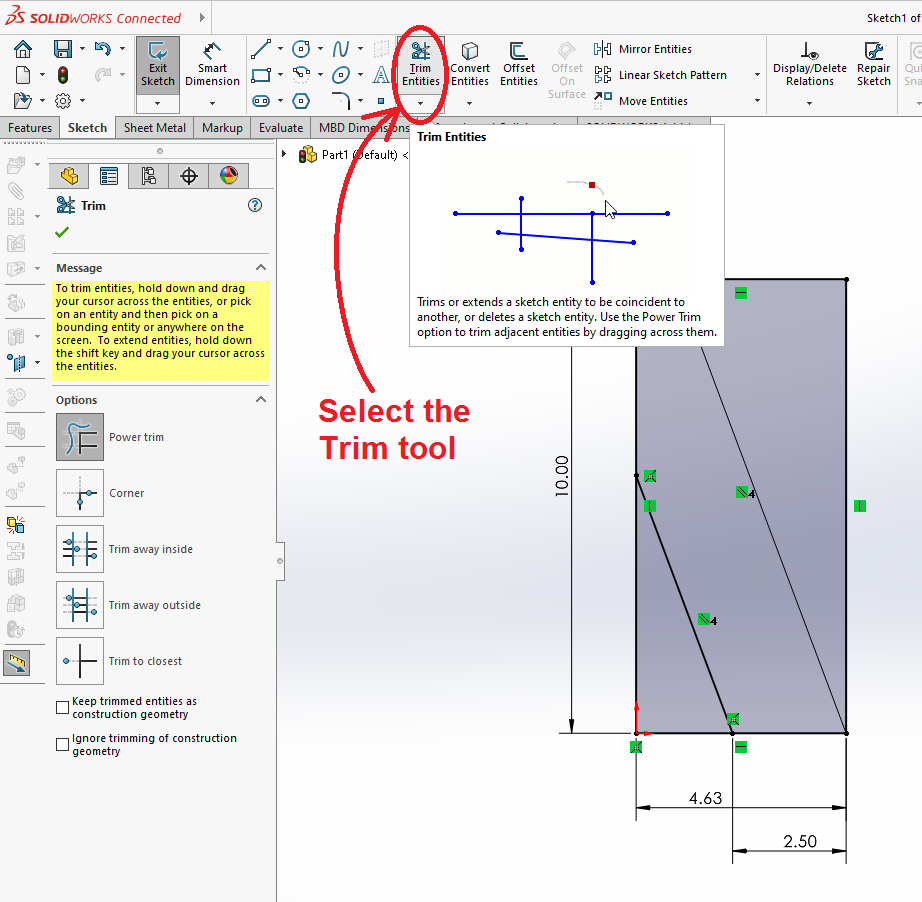

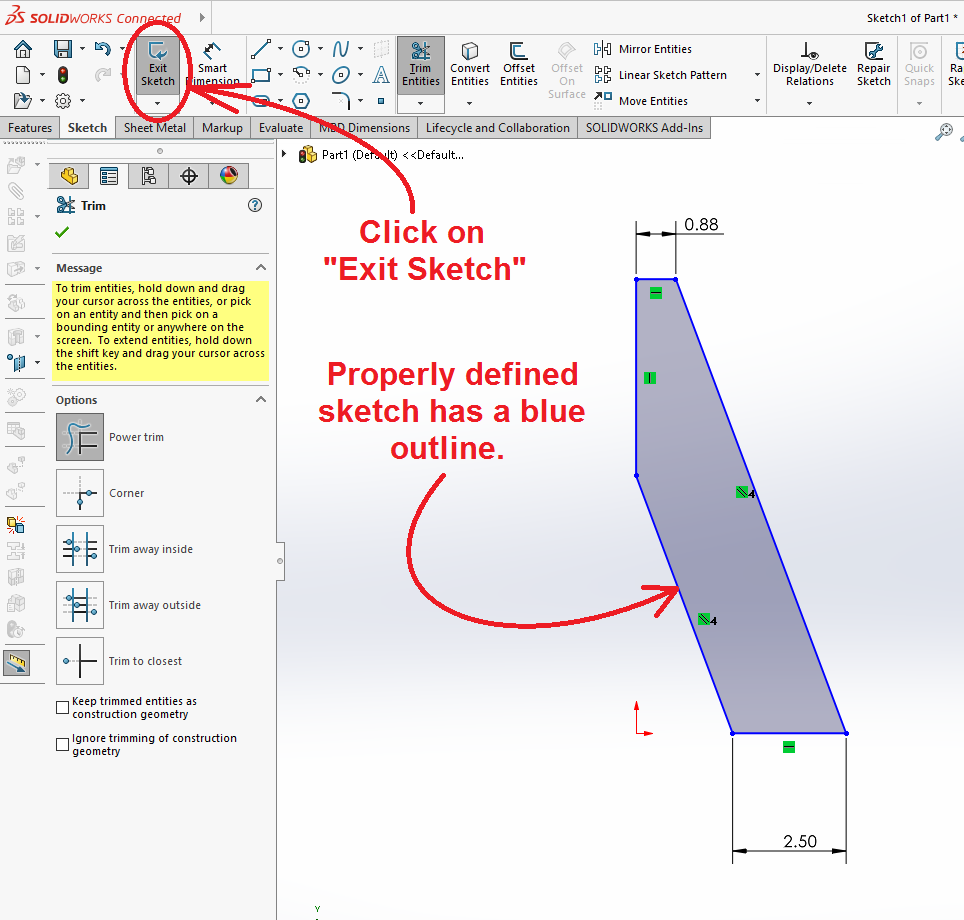

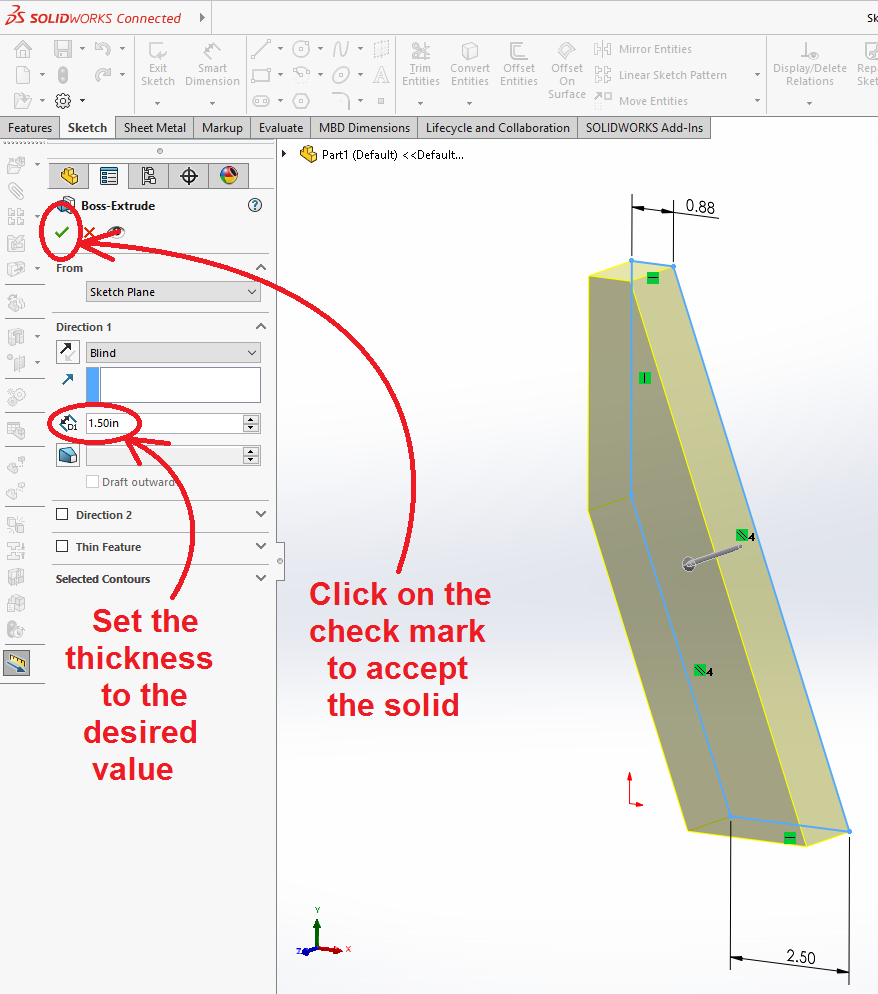

Creating an Extrusion

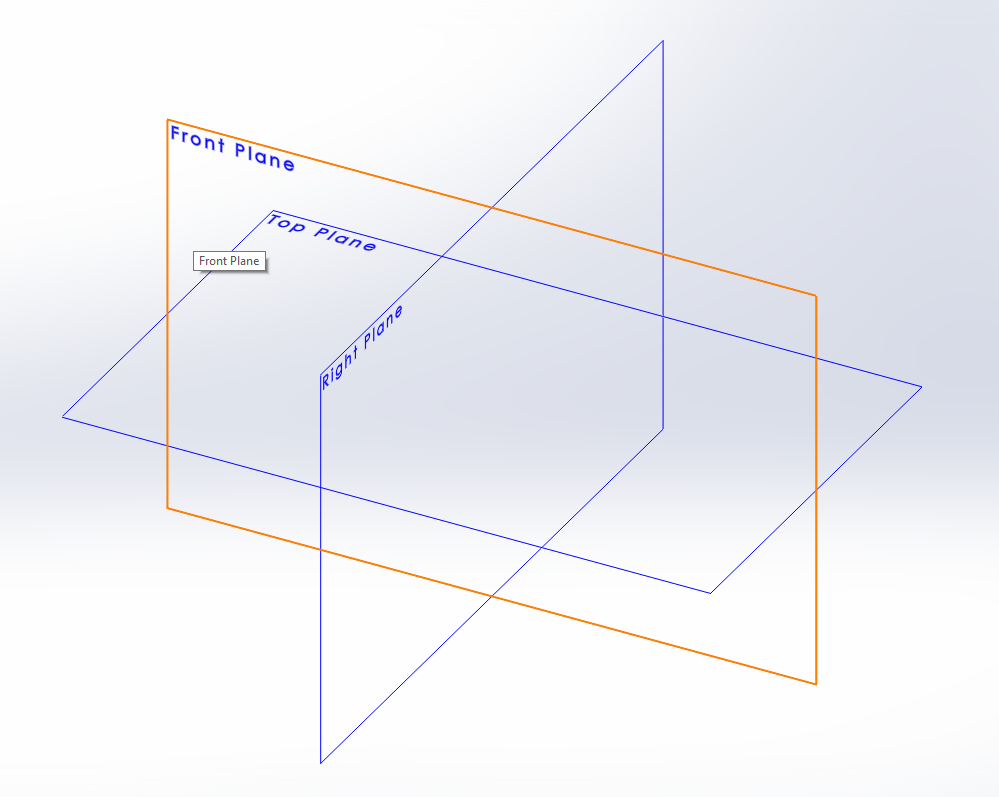

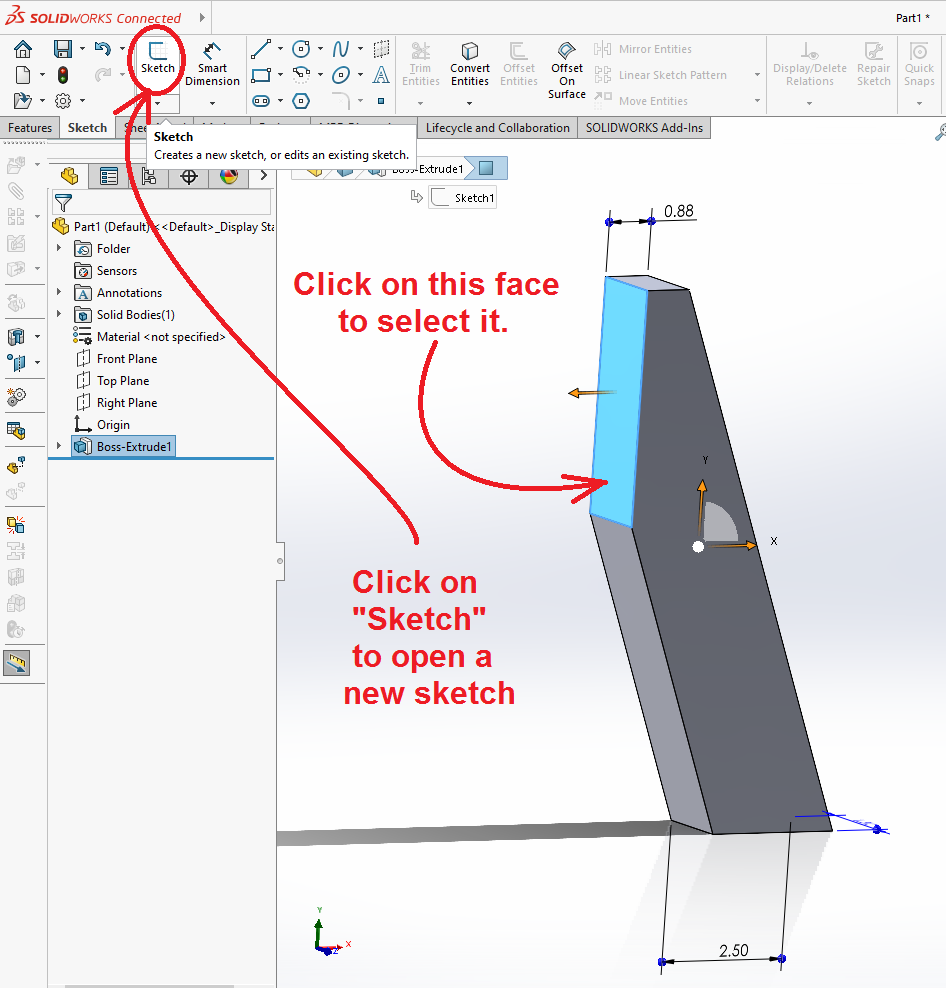

Select "Extruded Boss/Base" in the "Features" tab. Select a plane to sketch on.

Sketching the Outline of the Bracket

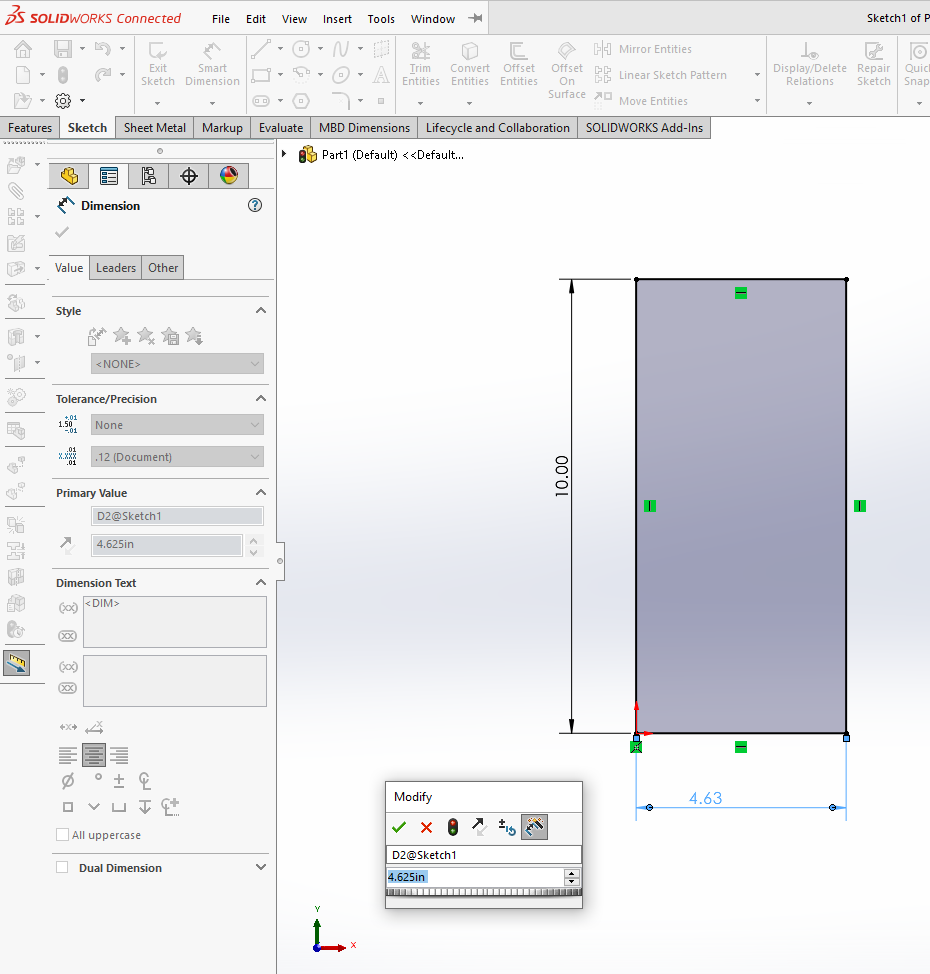

After selecting a sketch plane, a 2-D Sketch window will open. Select the rectangle tool, draw one, and dimension it as shown below left. If you are not sure how to do this please check here. Use Smart Dimension to set the rectangle size.

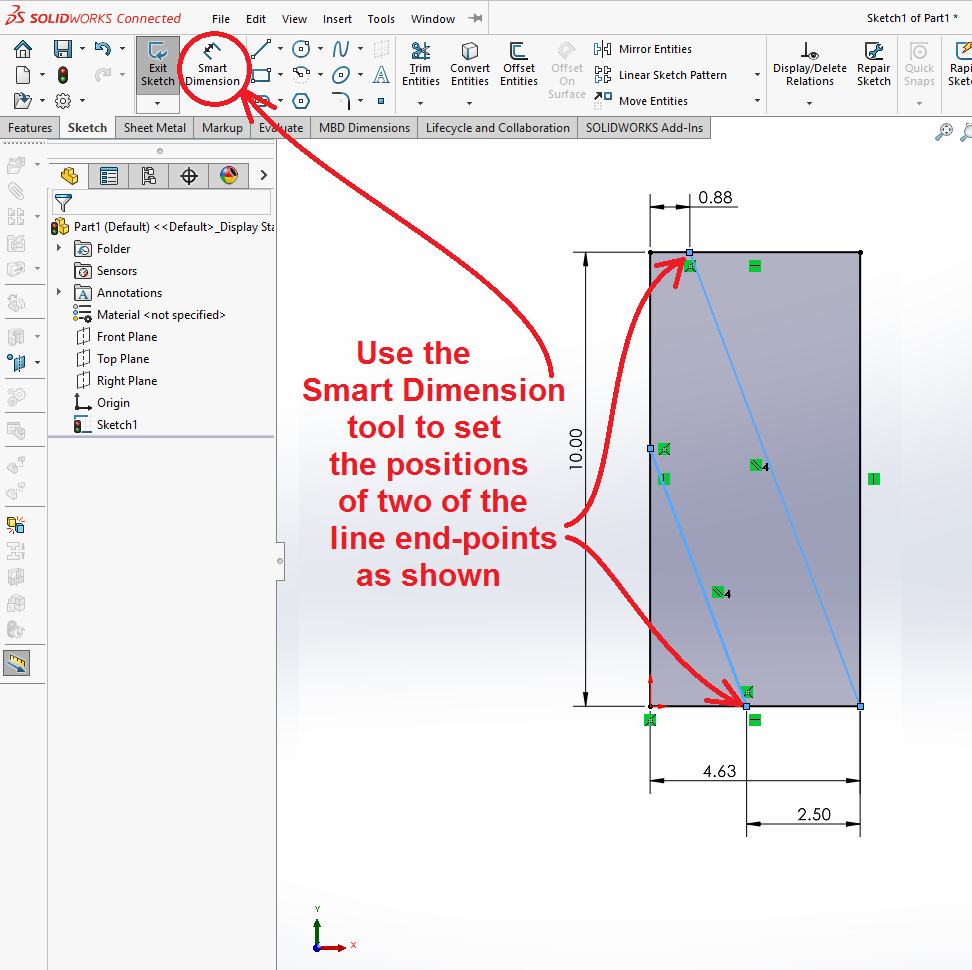

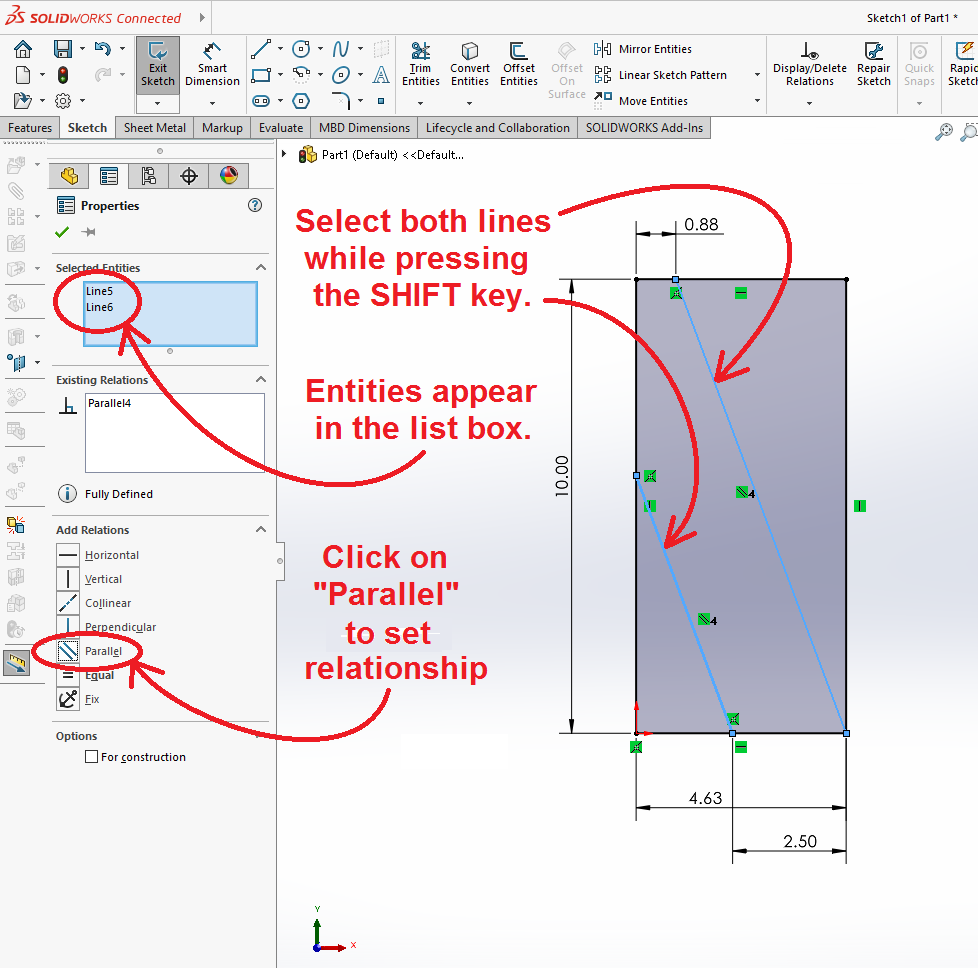

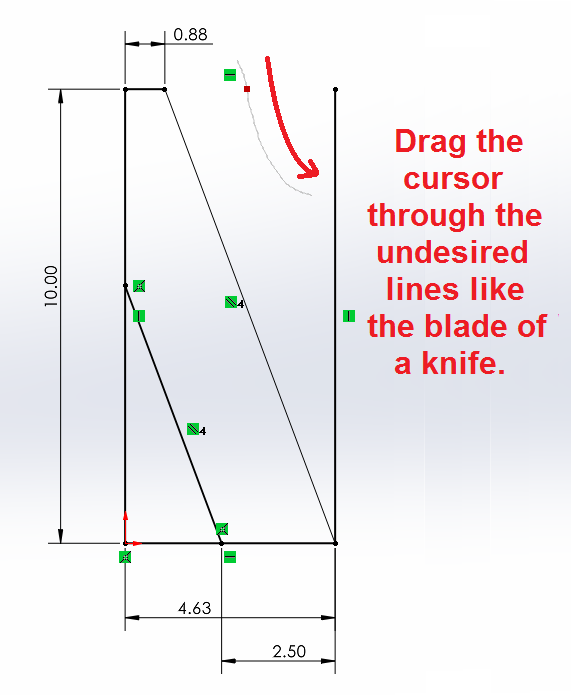

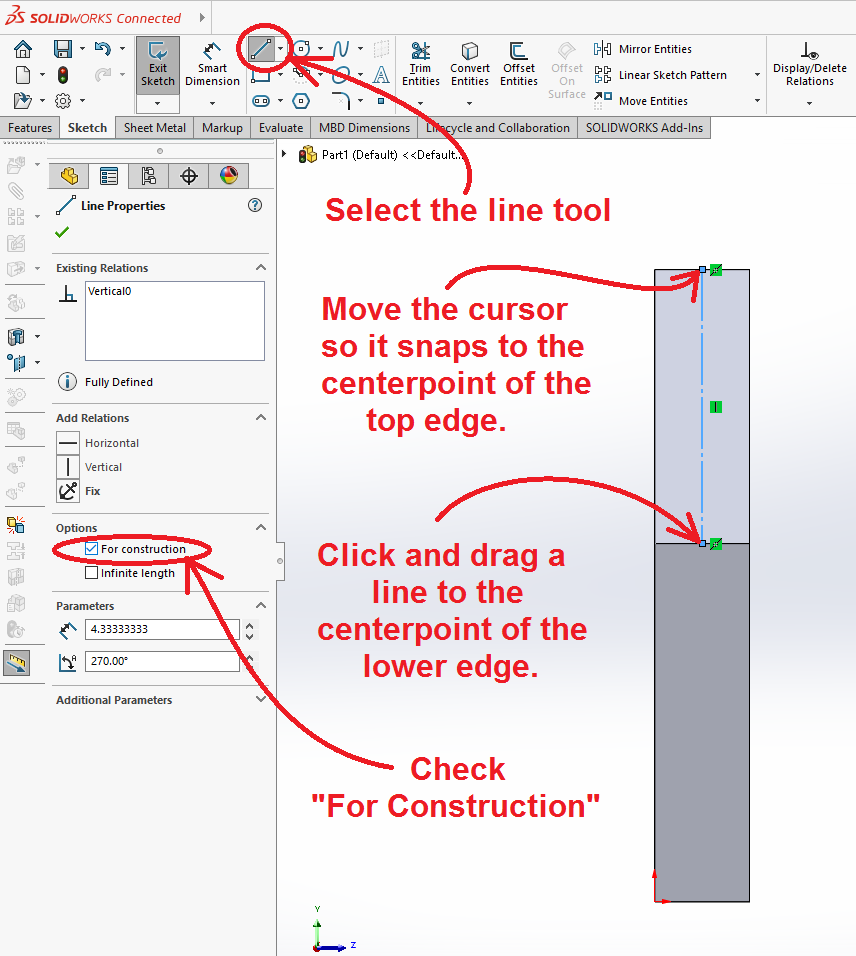

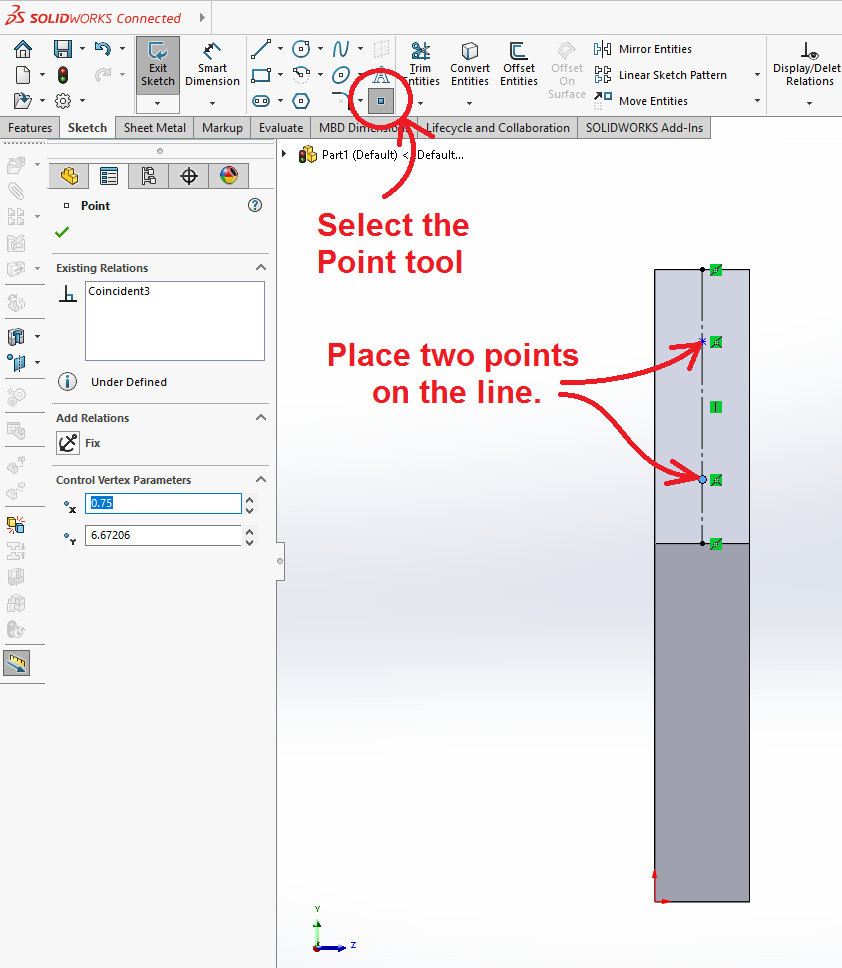

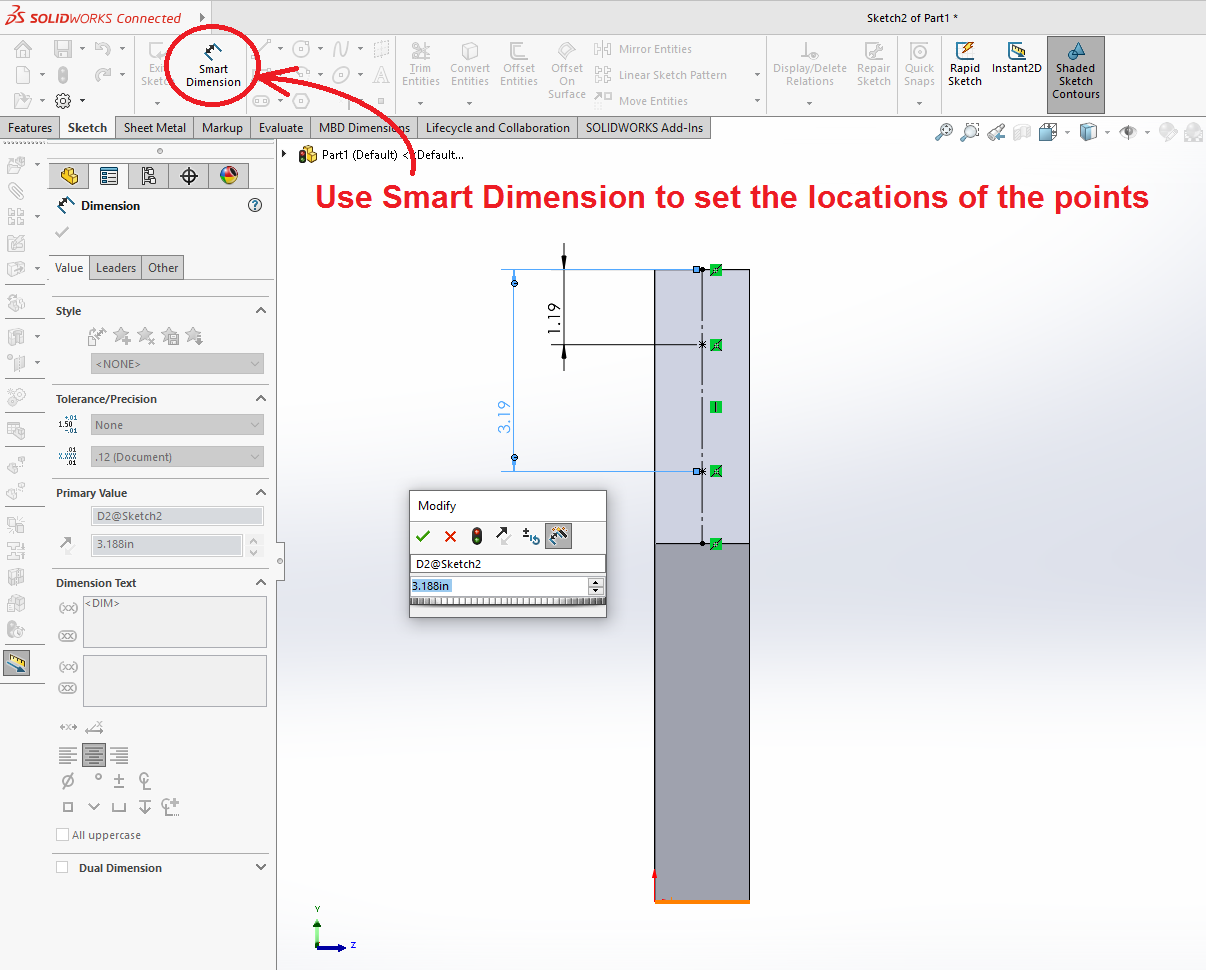

Select the line tool and draw two diagonals as shown inside the rectangle. Position the two line endpoint shown along the lower edge of the rectangle using Smart Dimension.