Fusion Tutorial 1b: Design of an Electronic Box, Continued

Link to: CAD Main Page

Link to: Tutorial 1a (prev)

Link to: Tutorial 1c (next)

Introduction

This tutorial is the second in a series teaching basic Fusion CAD sketching and modeling tools.

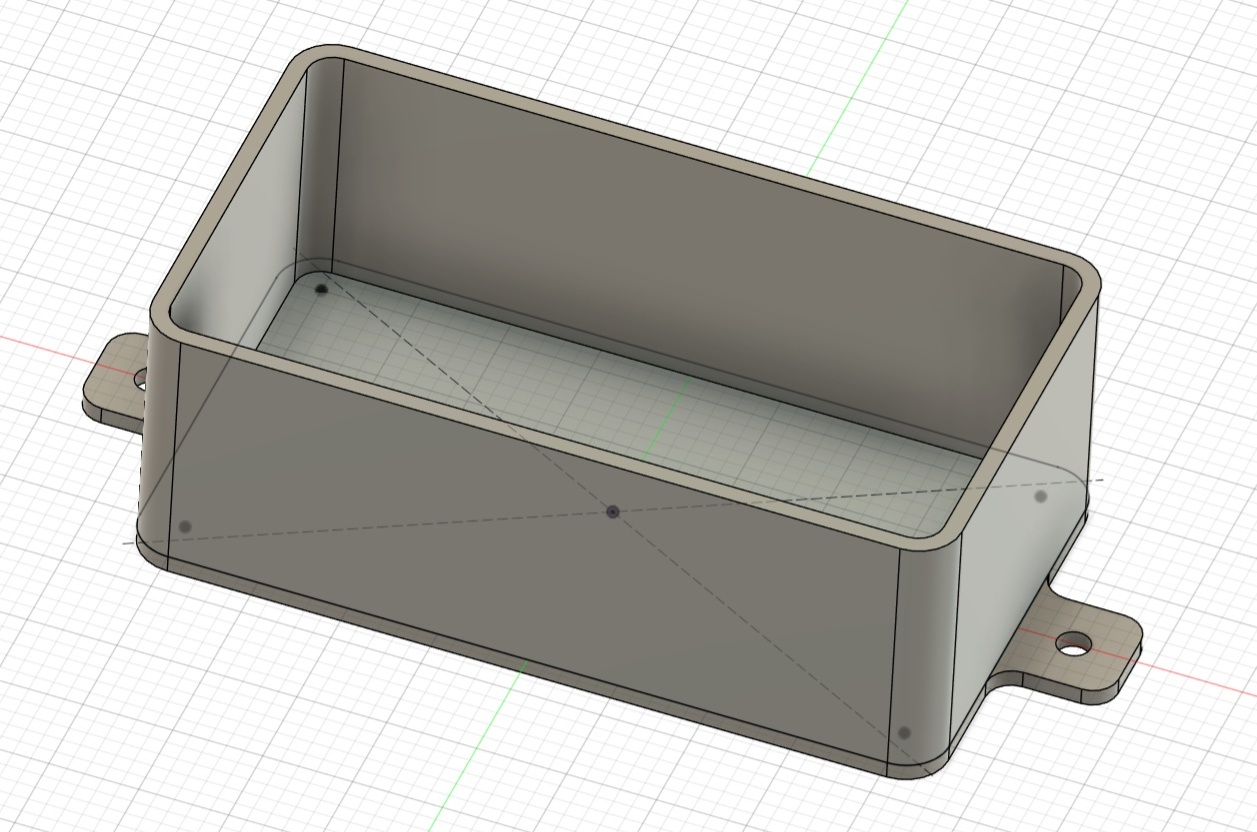

In the previous tutorial, we designed a simple hollow box. In this tutorial we will start to add the features that will give it its function: A sample electronics enclosure that could be made on a 3D printer.

In this page we will explore more aspects of sketching, (adding features to the surfaces of a simpler model) and adding geometric constraints between sketched features so that changes to the model's dimensions will carry through more smoothly. This is an example of parametric modeling. The goal is to tie together the features so only the minimum necessary set of dimensions needs to be displayed. Changes to the dimensions of the box can therefor be made easily and efficiently.

It is very common in 3D printing to build a part and find that some dimension has been specified wrongly. One of the consequences of the ease of making parts is mistakes are more frequent. The practice shown here allows design modifications to be made equally easily.

The pace of this tutorial will be somewhat faster than the previous one because knowledge of tools already presented will be assumed.

Sketch Mounting Lugs

Lugs to mount the E-box to a surface are the first features we will add to the design. We will repeat the sequence of opening a sketch on a plane, followed by extrusion into the third dimension.

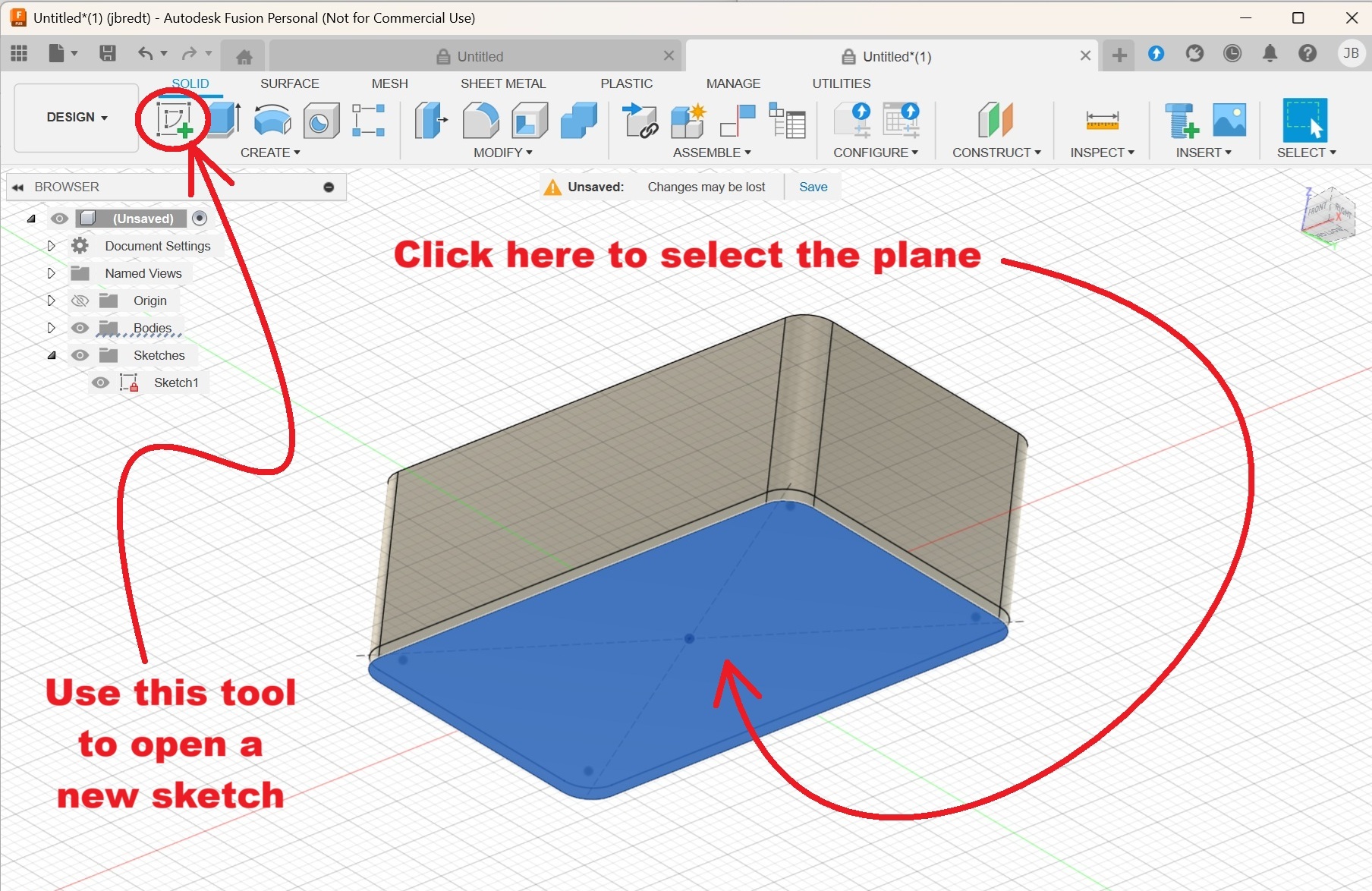

Open a New Sketch

Using the (![]() ) "Rotate" tool, turn the box over in the window so the box bottom is exposed. Click the cusor on the plane of the bottom to select it. Next, use the (

) "Rotate" tool, turn the box over in the window so the box bottom is exposed. Click the cusor on the plane of the bottom to select it. Next, use the (![]() ) "Sketch" tool to open a sketch on that plane.

) "Sketch" tool to open a sketch on that plane.

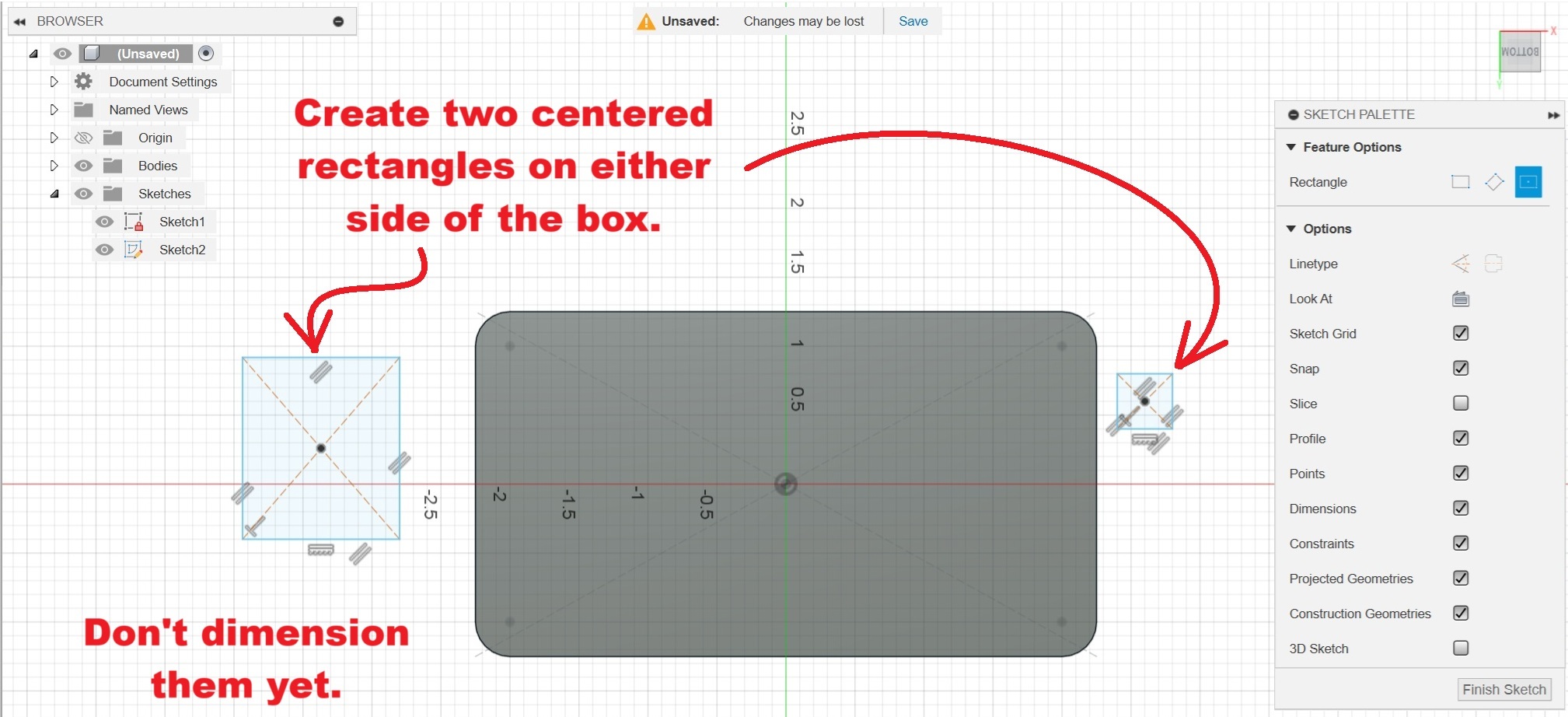

Use the (![]() ) "Rectangle" tool to sketch two (

) "Rectangle" tool to sketch two (![]() ) "Center" rectangles off the sides of the box bottom. They need not be the same size at this point: We will apply geometric constraints that will help fix the dimensions.

) "Center" rectangles off the sides of the box bottom. They need not be the same size at this point: We will apply geometric constraints that will help fix the dimensions.

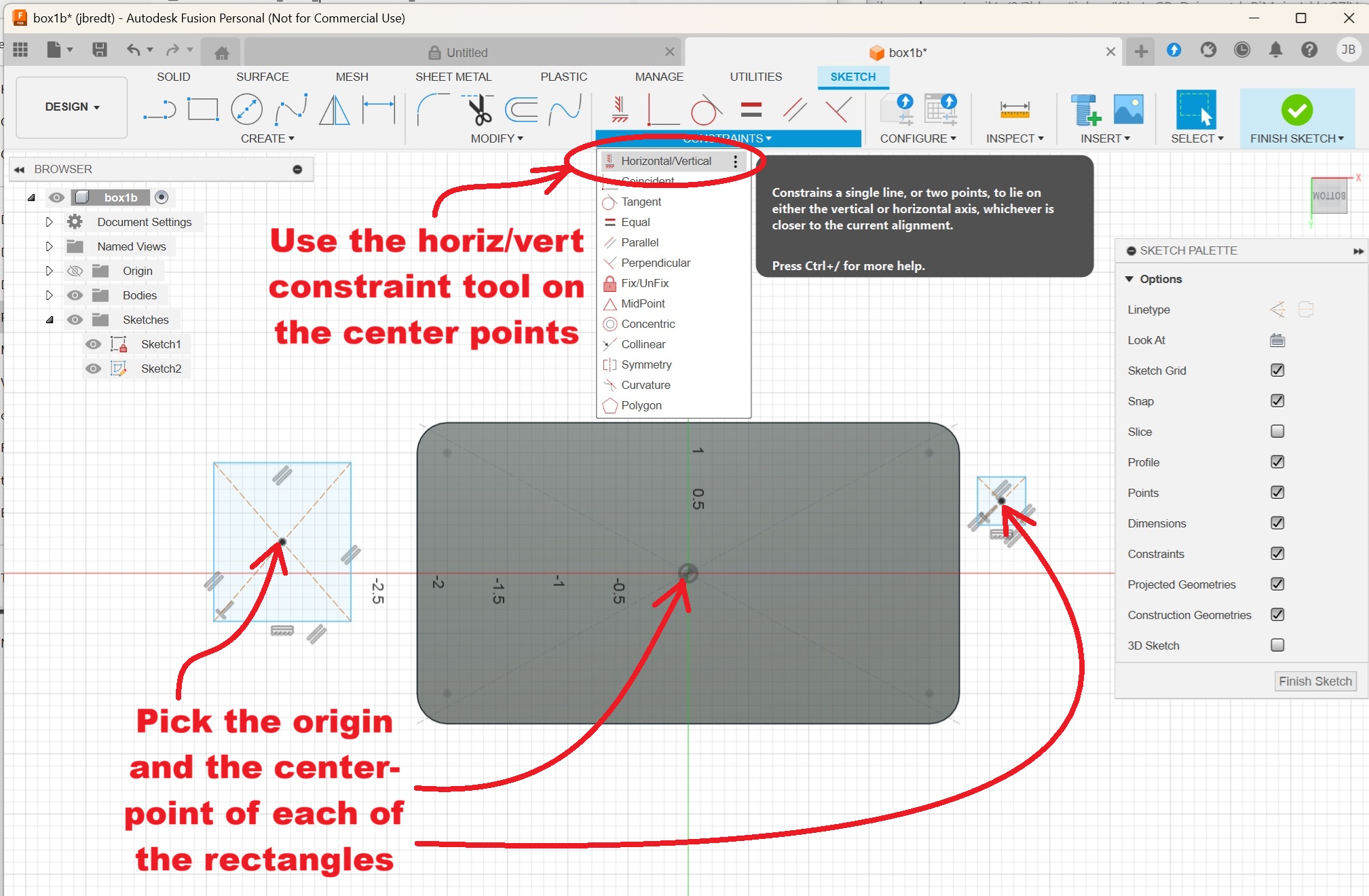

Apply Constraints

- First we constrain the centers of the two rectangles to sit on the X-axis. In the "Constraints" group in the tool-bar, select the (

) "Horizontal/Vertical" constraint tool. This tool works by getting the user to pick points in pairs. Click on the ORIGIN as one of the points, followed by one of the center points of the rectangles you just drew.

) "Horizontal/Vertical" constraint tool. This tool works by getting the user to pick points in pairs. Click on the ORIGIN as one of the points, followed by one of the center points of the rectangles you just drew.

As you make these selections you should see the rectangle centers snap to the X-axis in the sketch.

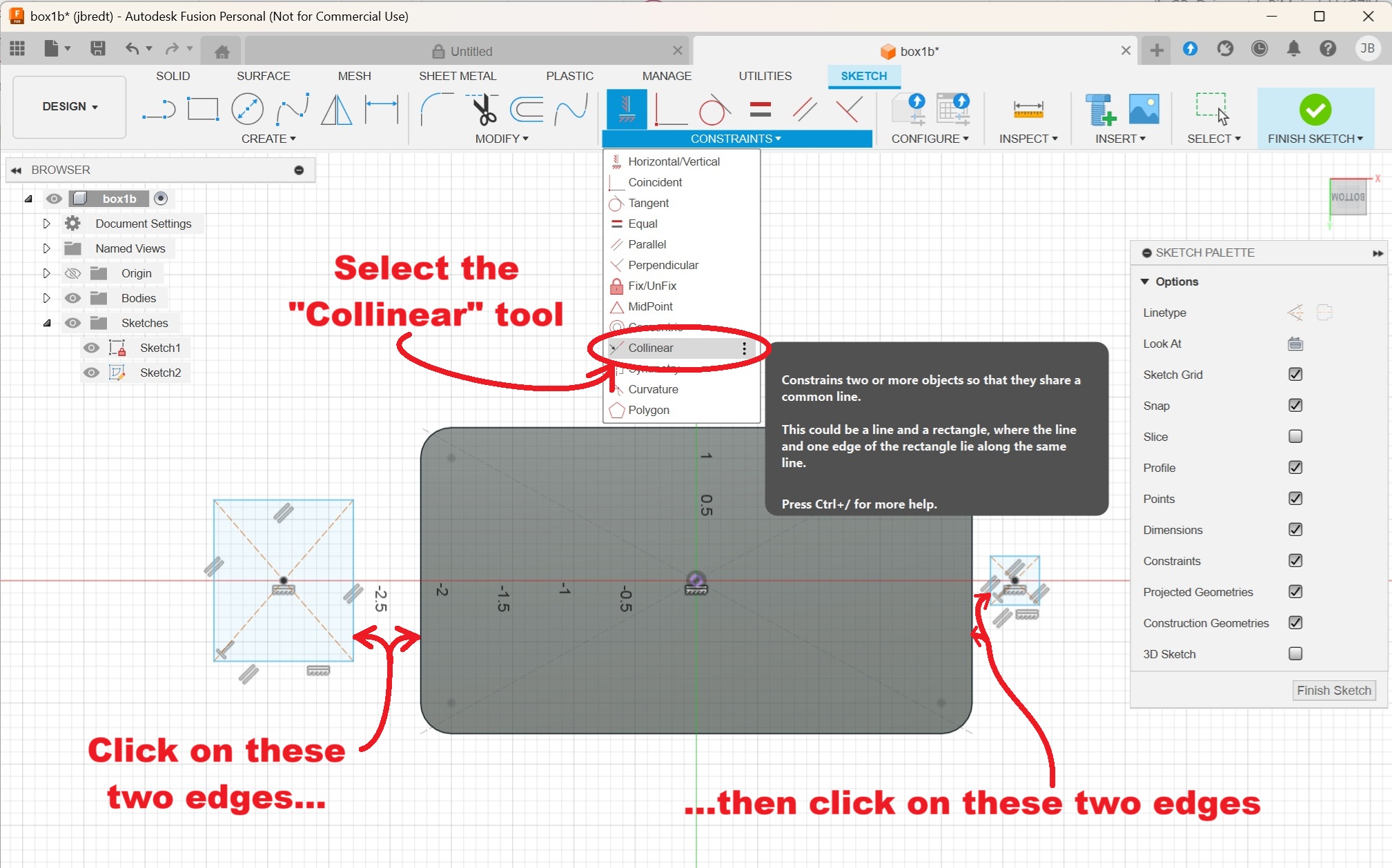

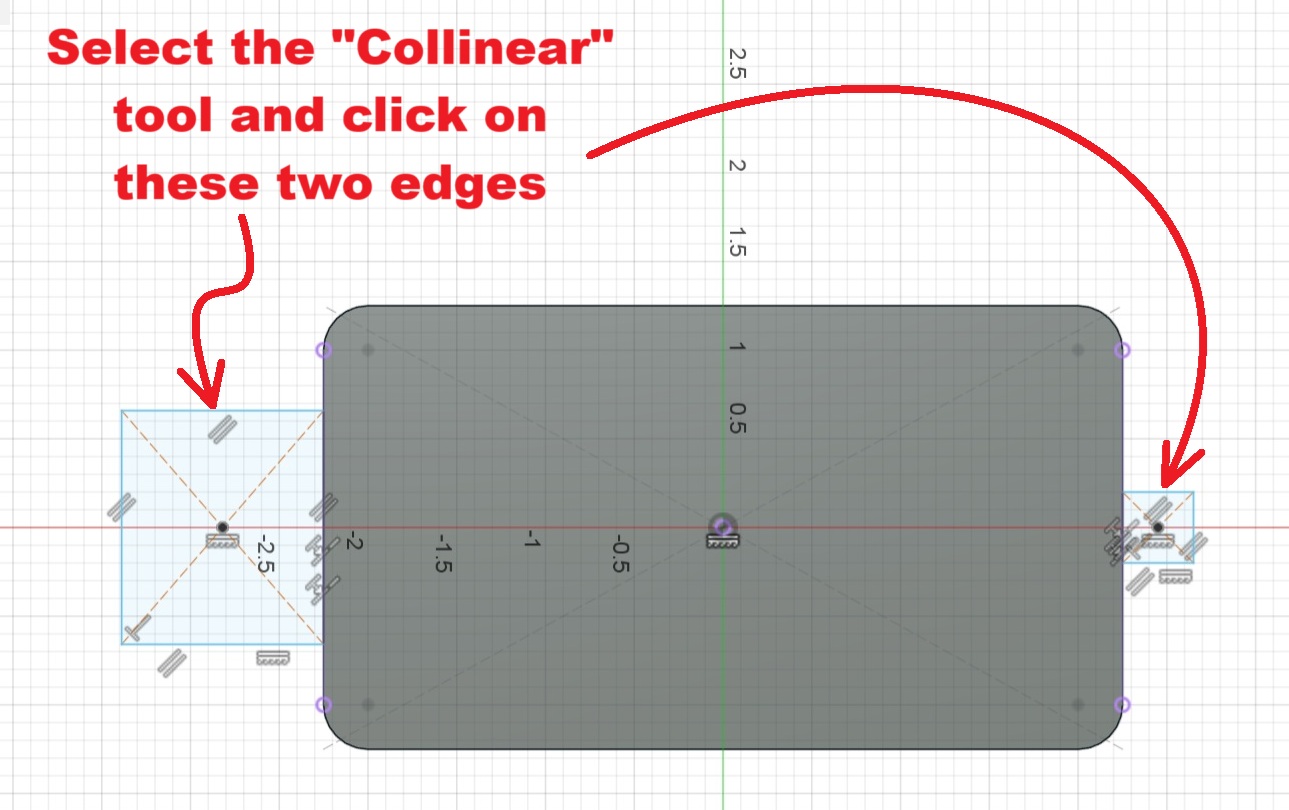

- Next we set the edges of the rectangles to sit on the edges of the box bottom. From the "Constraints" menu, select the (

) "Collinear" tool. Click on adjacent vertical edges to link the sides of the box bottom with the corresponding edges of the two rectangles.

) "Collinear" tool. Click on adjacent vertical edges to link the sides of the box bottom with the corresponding edges of the two rectangles.

You should see the edges of the rectangles snap to the sides of the box bottom.

- Next we tie the heights of the rectangles together. With the (

) "Collinear" tool still selected, click on the upper horizontal sides of the two new rectangles.

) "Collinear" tool still selected, click on the upper horizontal sides of the two new rectangles.

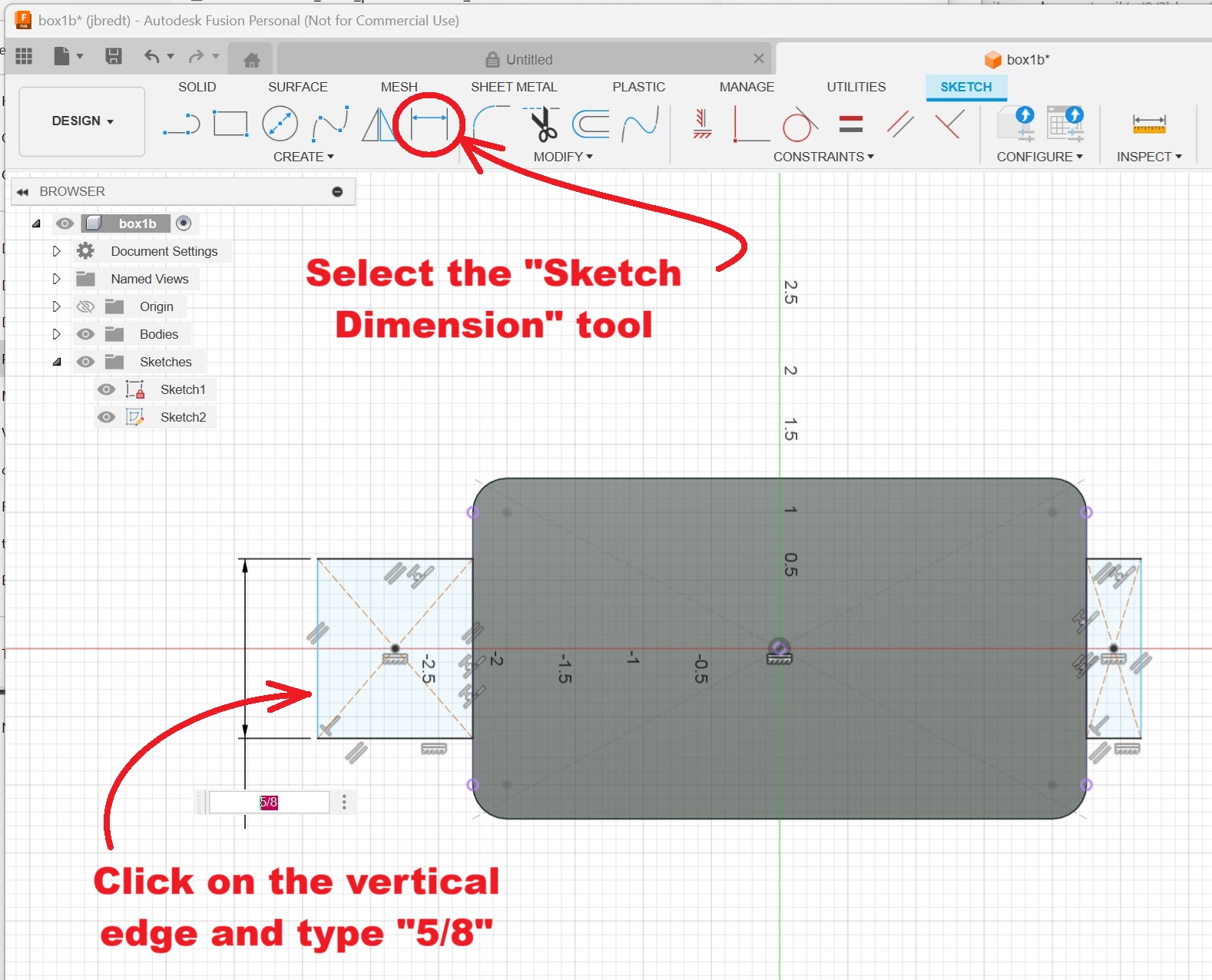

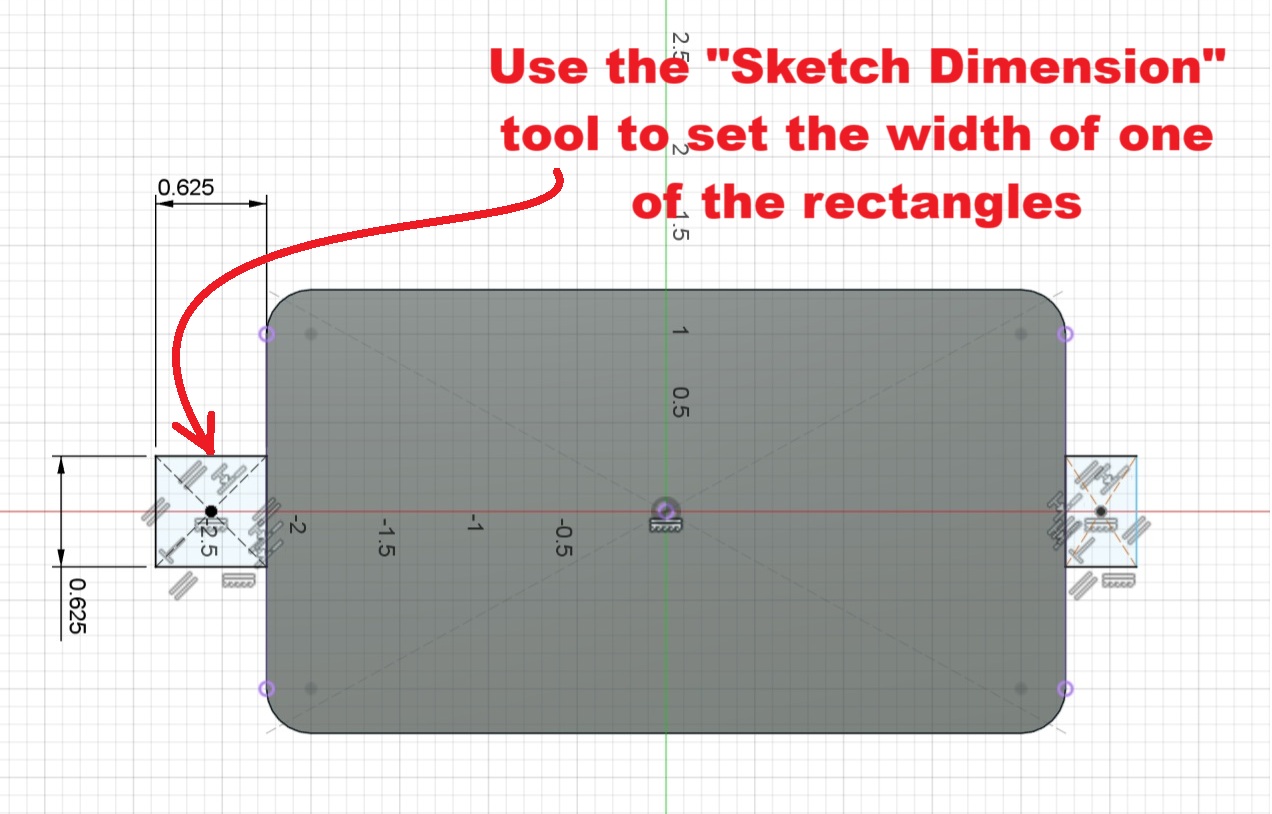

- Now we dimension the heights of the rectangles. In the "Create" group in the tool-bar, select the (

) "Sketch dimension" tool. Click on the outer vertical side of one of the new rectangles. A set of dimension bars should appear with an edit box associated with them. Drag the displayed dimension to a convenient location and type "5/8" into the edit field. When you hit the -ENTER- key the application should replace the fraction with its decimal equivalent: 0.625 in.

) "Sketch dimension" tool. Click on the outer vertical side of one of the new rectangles. A set of dimension bars should appear with an edit box associated with them. Drag the displayed dimension to a convenient location and type "5/8" into the edit field. When you hit the -ENTER- key the application should replace the fraction with its decimal equivalent: 0.625 in.

Both rectangles should move together to the revised height.

- Set the width of one of the rectangles also to 5/8". We will use the (

) "Equal" constraint tool later to fix the width of the other rectangle.

) "Equal" constraint tool later to fix the width of the other rectangle.

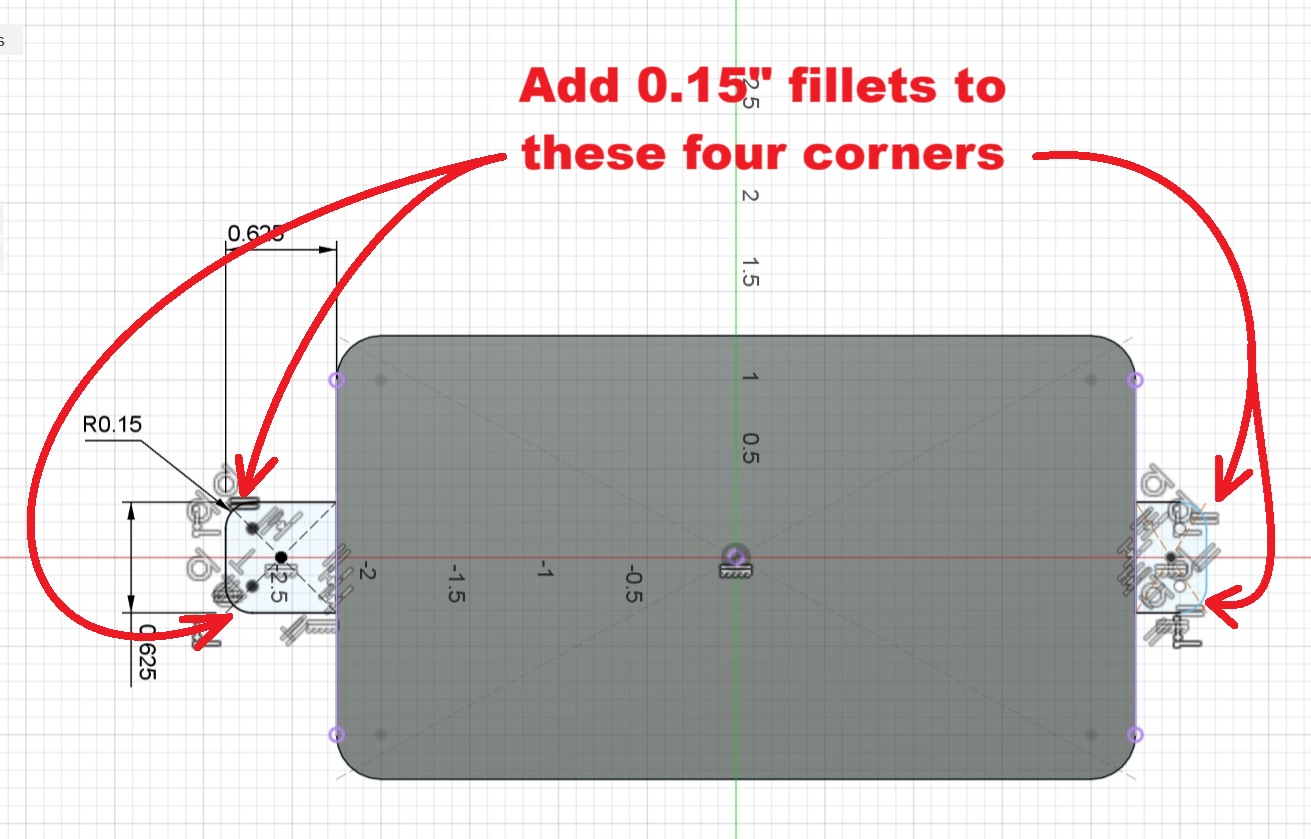

Add Fillets

Use the (![]() ) "Fillet" tool to round the outside corners of the new rectangles. Set the radii to 0.15 inches. If you are unclear how to do this, please review the fillet procedure in the previous tutorial.

) "Fillet" tool to round the outside corners of the new rectangles. Set the radii to 0.15 inches. If you are unclear how to do this, please review the fillet procedure in the previous tutorial.

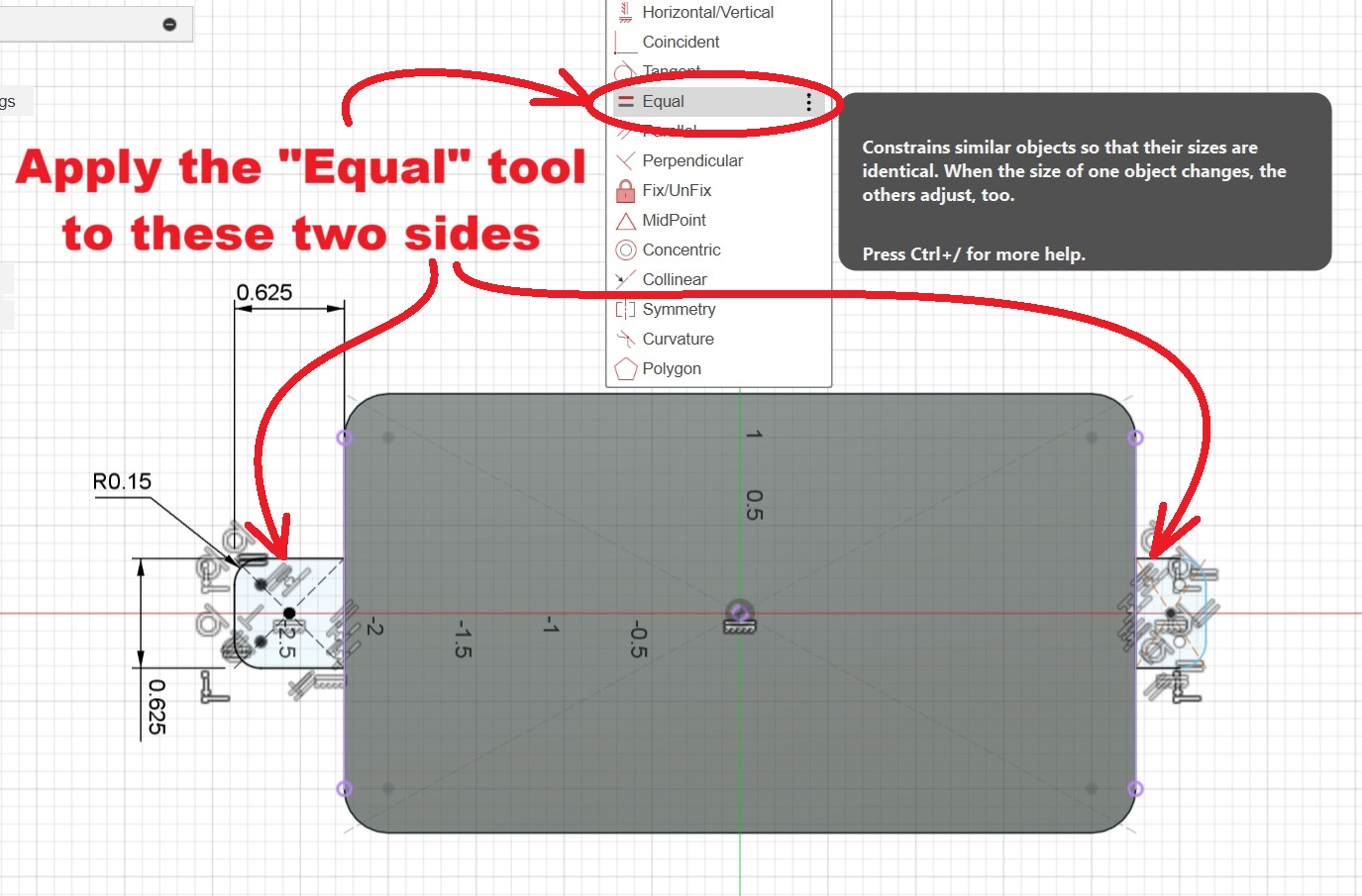

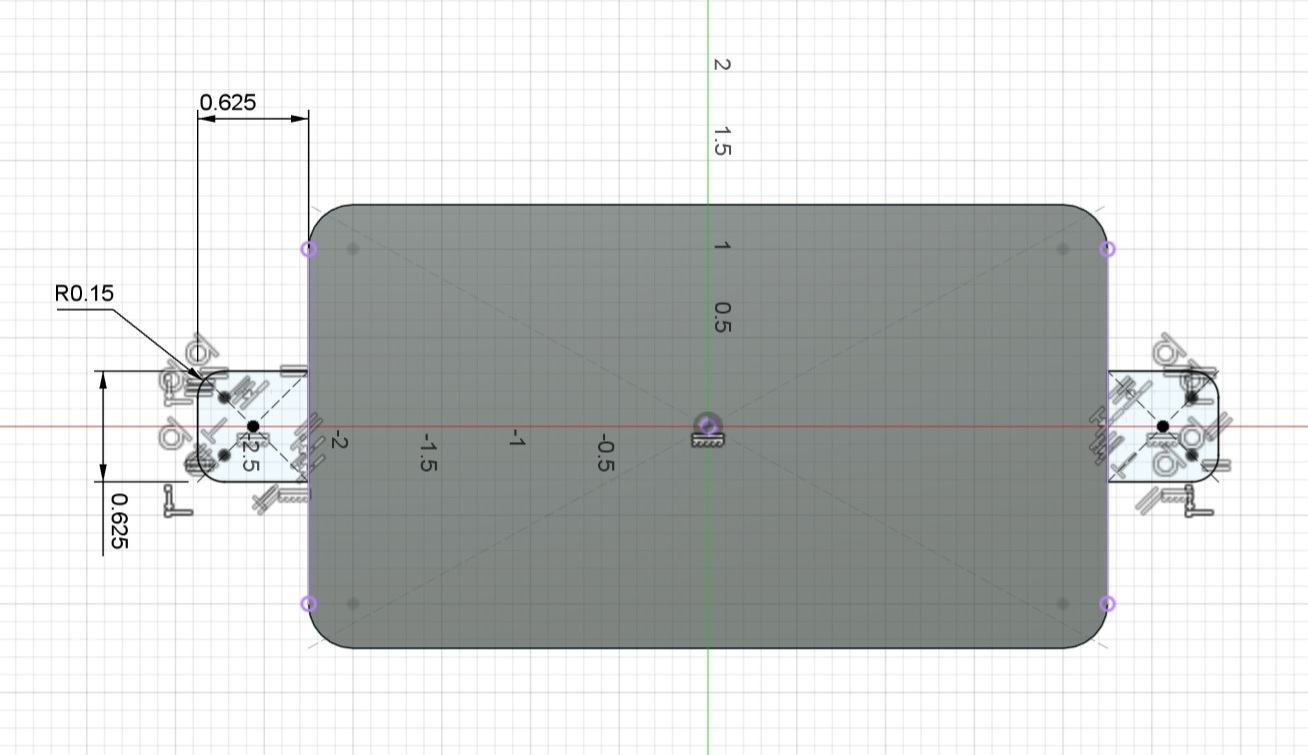

Add One Last Constraint

To finish the dimensioning of the rectangles, select the (![]() ) "Equal" constraint tool and click on the top horizontal straight sections of the rectangles on either side.

) "Equal" constraint tool and click on the top horizontal straight sections of the rectangles on either side.

The reason this step must be done AFTER the fillets are added is the fillets shorten the lengths of the sides and the application automatically removes length constraints when they are added.

You should check to make sure the constraints have been set properly. There are only three dimension displayed in the sketch. If you double-click on any of them an edit box will open and you can change the value. Make sure that changing the value applies to ALL of the features that are supposed to be the same.

This is an exercise of "parametric" modeling.

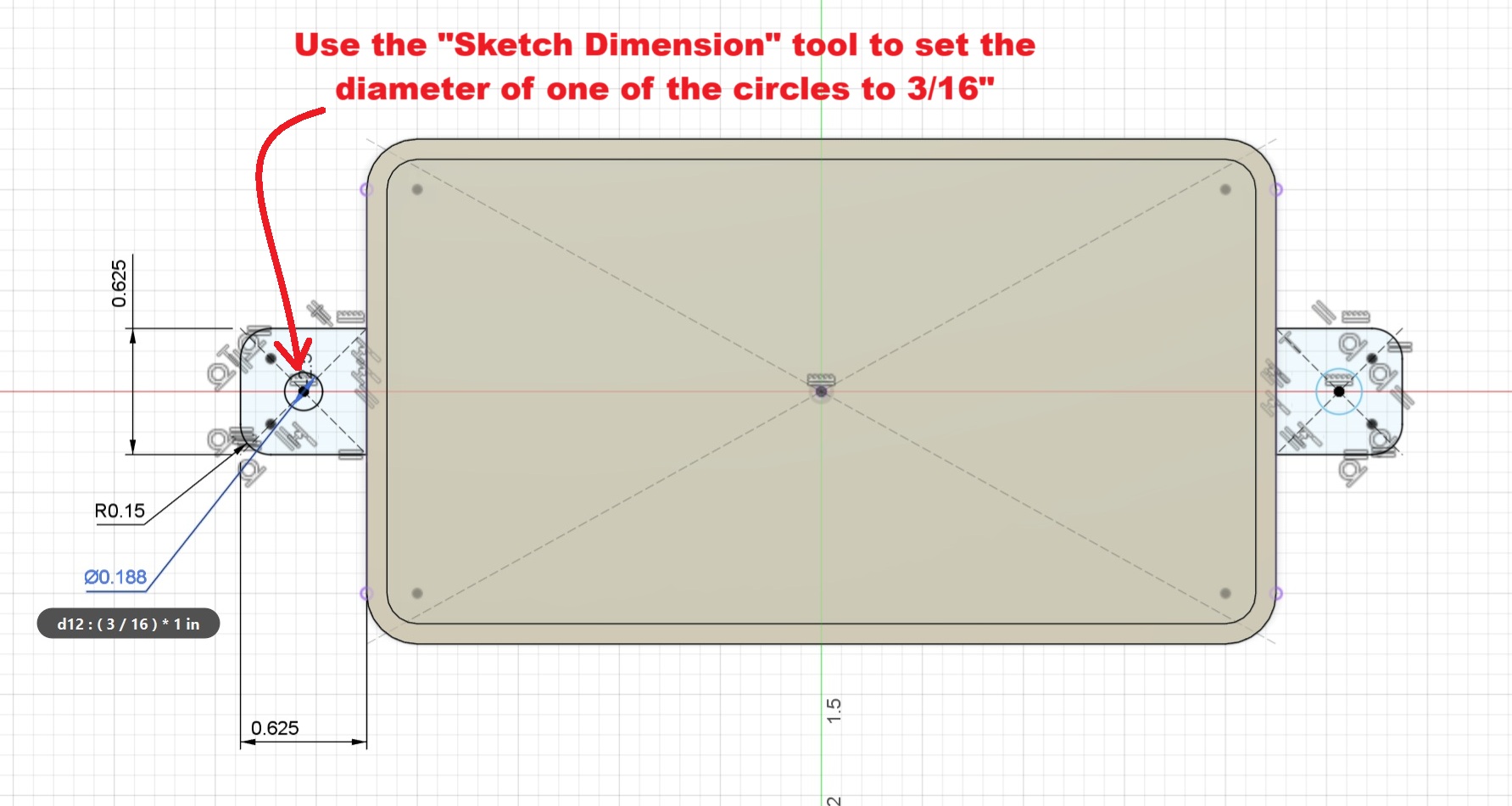

Add Screw Holes to the Lugs

To finish the mounting lugs, we use the (![]() ) "Circle" tool from the "Create" tool group. These will form screw holes in the lugs.

) "Circle" tool from the "Create" tool group. These will form screw holes in the lugs.

Select the tool from the tool bar. Click on the center point of one of the rectangles to attach the hole center to it. Drag the mouse out sideways (like with the center rectangles) to make a circle of some size. Do the same in the rectangle on the other side.

Select the (![]() ) "Sketch dimension" tool and set the diameter of one of the circles to 3/16". Now use the (

) "Sketch dimension" tool and set the diameter of one of the circles to 3/16". Now use the (![]() ) "Equal" constraint tool to make the second circle match the first one.

) "Equal" constraint tool to make the second circle match the first one.

Click on the "Finish Sketch" button to exit the sketch and add it to the design.

Extrude the Lugs

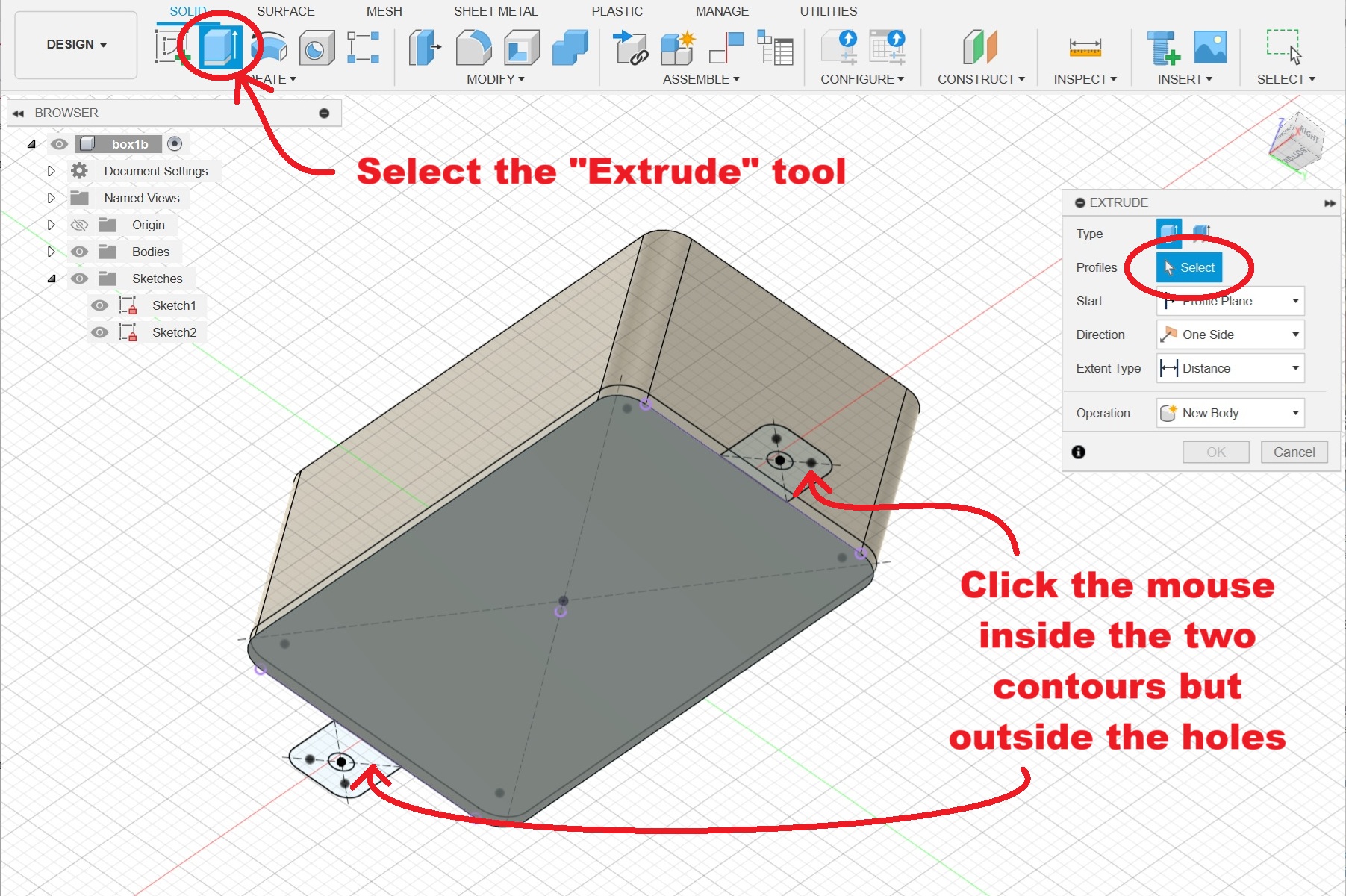

Notice that a second sketch, named "Sketch 2" has been added to the list of features in the upper-left corner of the window. Make sure this sketch is selected when you click on the (![]() ) "Extrude" tool in the "Create" group of the tool bar.

) "Extrude" tool in the "Create" group of the tool bar.

A dialog box will open that prompts you to select contours to extrude. The first time we did this there was only one contour. This time there are several. You need to click on areas that you intend to make solid. In this case you should click the mouse on the areas of each lug profile OUTSIDE the circular features that will form holes.

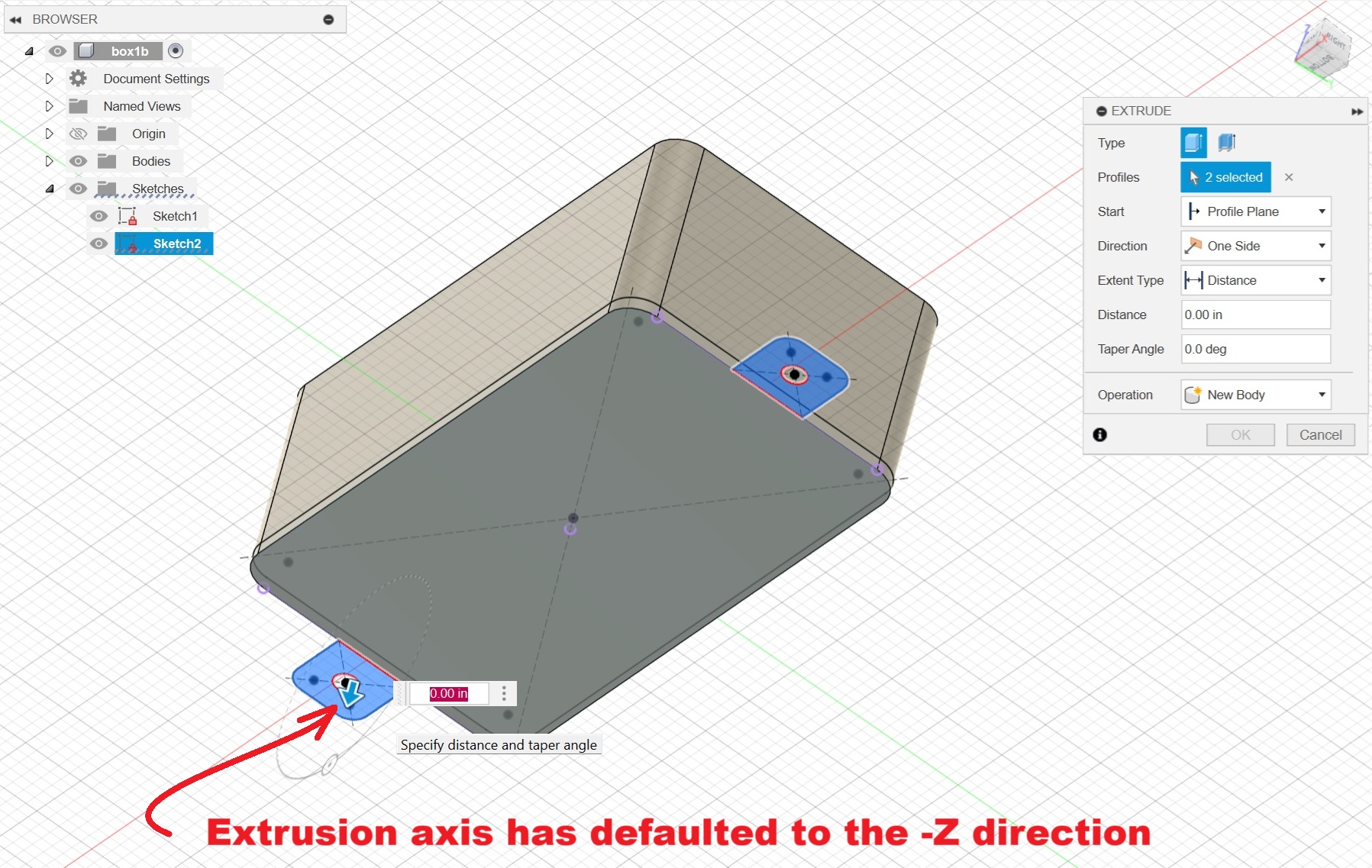

Once the selection is made an arrow will appear showing the "positive" direction for extrusion. In the view shown, the box has been rotated so the box bottom is visible. The application defaults to the direction that points towards the viewer, in this case, the NEGATIVE-Z direction.

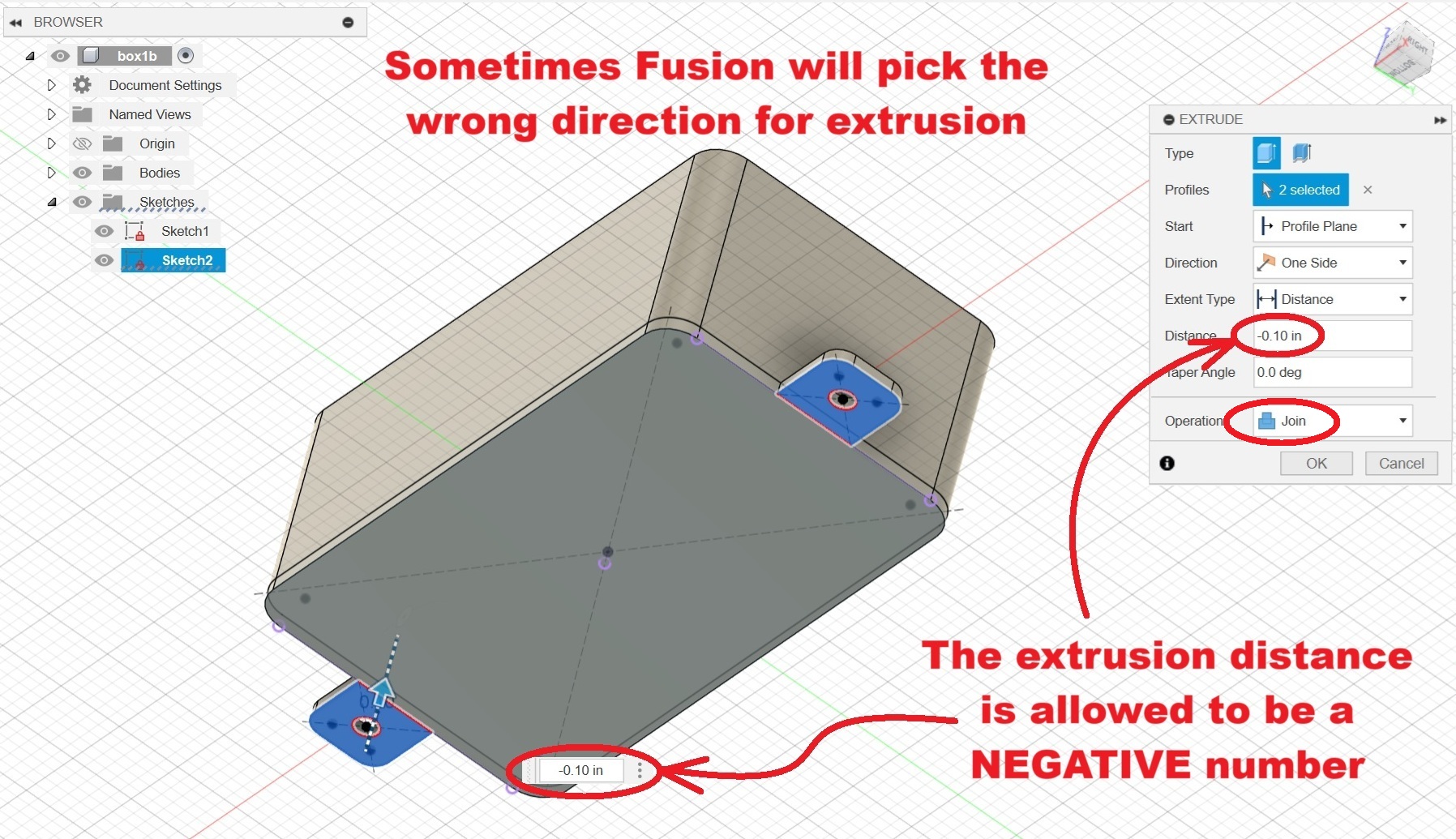

If we extrude the new solids in this direction, the lug bodies will be disconnected from the box. Fortunately, all you need to do is specify a NEGATIVE number for the extrusion distance. This will project the solid lugs in the POSITIVE-Z direction.

You can also click the mouse on the arrow and drag it to the correct direction. This will invert the extrusion axis and allow you to specify a positive number if you so desire.

You should be able to see a preview of the extruded solids in the correct orientation. Make sure the "Operation" field in the dialog box says "Join".

Hit the "OK" button to accept the features and add them to the design.

Fillet the Inside Corners

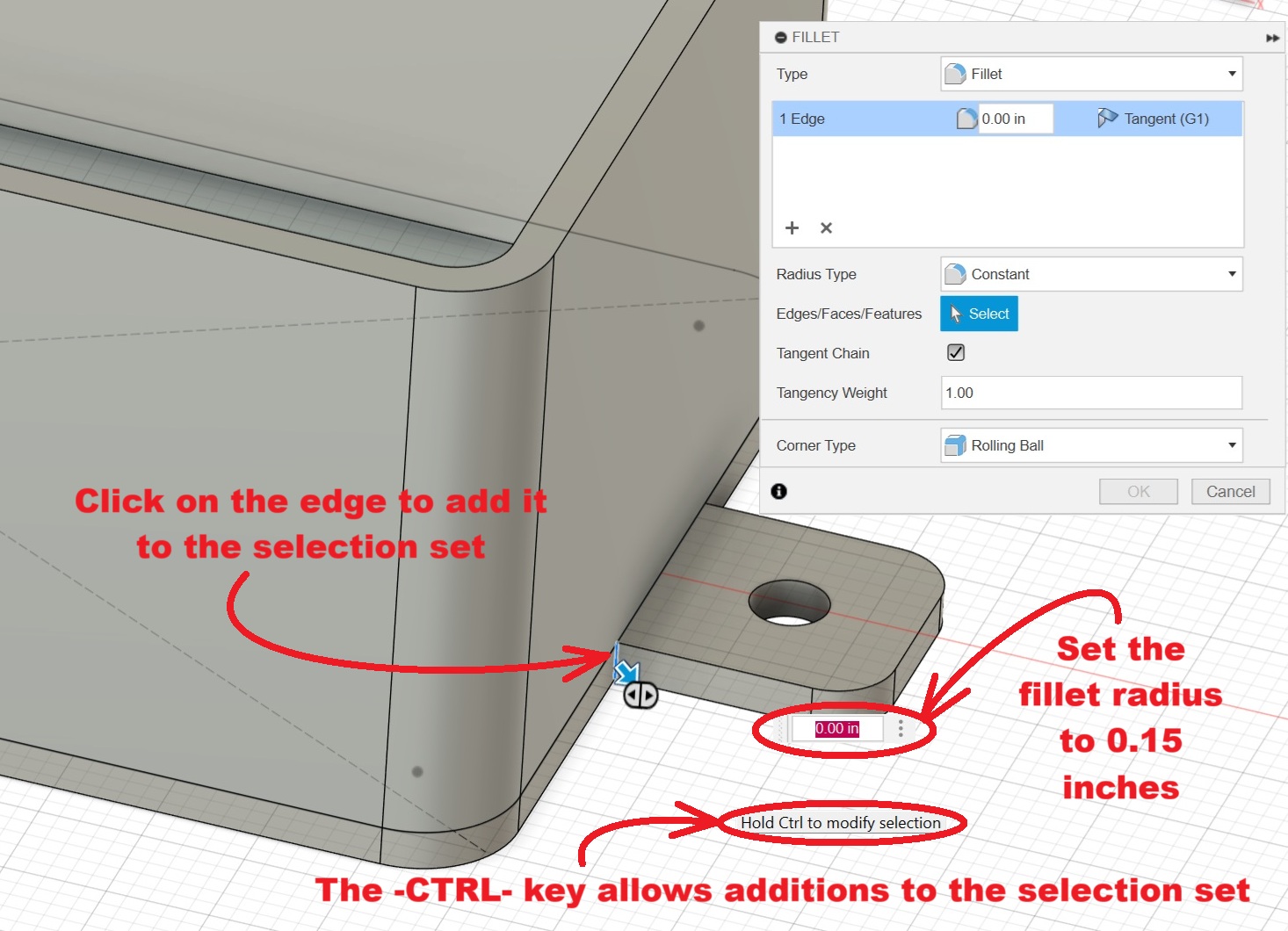

If you look closely at the box at this point, you will notice the new lugs attach to the box with square inside corners. This isn't a good mechanical design for parts made on a 3D printer. We need to fillet these corners so the lugs won't easily crack at these corners.

In the "Modify" group of the tool-bar, select the (![]() ) "3D Fillet" tool. This is analogous to the tool in the sketching workspace, but instead of selecting a corner between two line segments, you select a 3D edge on the surface of the solid object.

) "3D Fillet" tool. This is analogous to the tool in the sketching workspace, but instead of selecting a corner between two line segments, you select a 3D edge on the surface of the solid object.

The tool opens a dialog box that features a list box with the selection set displayed.

You will need to zoom in on the view and rotate it around to accurately select the necessary edges. To add the four edges to the selection set, rotate the view around to find each edge, press the -CTRL- key, and click on the edge.

Notice if you hover the cursor over the location of a hidden edge, the edge will appear and you can click on it. This eases the necessary amount of navigation.

Set the fillet radius to 0.15 inches to match the radii of the fillets on the outside corners of the lugs.

Hit the "OK" button to accept the features and add them to the design.

3D fillets are formed in the design using a tool that doesn't incorporate a sketch. Up to now, we have found that any feature or dimension could be modified by re-opening the sketch that formed it. With 3D fillets this is not the case. Fillets can't be deleted but you can modify the radius of the set of fillets using the (![]() ) "Push/Pull" tool in the "Modify" group. Click on the tool and click on the fillet to open an interactive dialog box.

) "Push/Pull" tool in the "Modify" group. Click on the tool and click on the fillet to open an interactive dialog box.

Conclusion

This is the end of Fusion tutorial 1b.

We have designed some mounting features and added them to the box from Tutorial 1a. In this tutorial we have used the dimensional constraint tools to define the shapes with only five independent dimensions: The length and width of both lugs, the diameter of both screw holes, and the radii of two sets of fillets. Changing any of these dimensions in the design should apply to all of the lugs and fillets.

At this point we have covered most of the basic modeling tools necessary to develop simple designs in Fusion. There are useful tools that are still to be presented, and there are additional features needed in the E-box. These will be covered in the next tutorial in the series, Tutorial 1c.