Category:3D Printers - Extrusion

| FDM Printers | |

|---|---|

| General Info | |

| Make | various |

| Model | |

| Serial | |

| Specs | |

| Manual | |

| Asylum Info | |

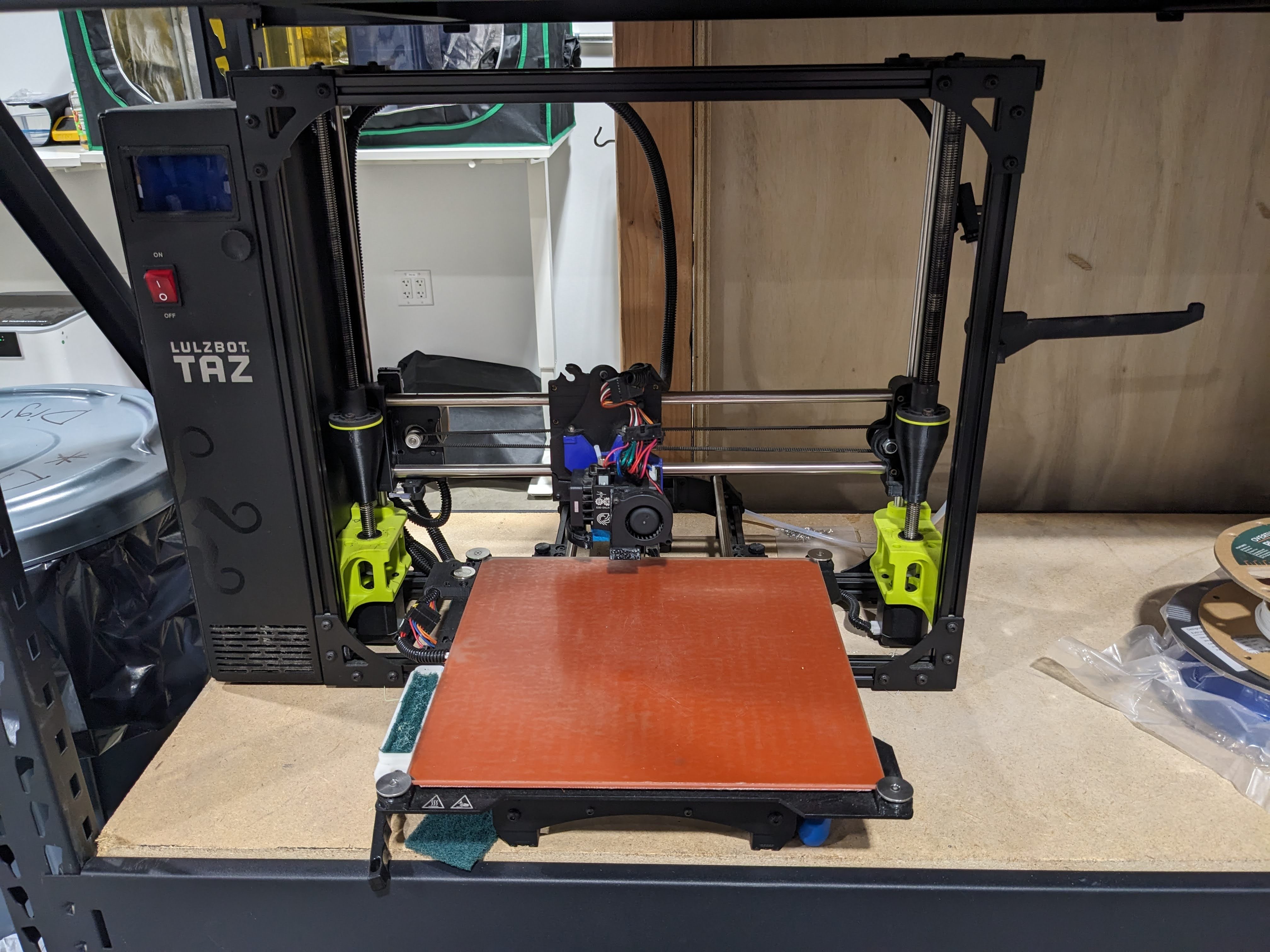

| Location | Digifab |

| Rubric | |

| Training | |

| Testing | |

| Restrictions | red |

Description

3D printers in general consist of a robot with a material dispenser attached to it. The user sends digital data to the printer that encodes a shape to be built. The machine then executes a program that dispenses material in a pattern that coincides with the desired shape. Additionally the machine may also create ancillary structures to support the shape during the build job. After the part is built, it is removed from the machine and may be subjected to various post-processing operations to finish it.

Extrusion-type 3D printers (Also called FDM for Fused Deposition Modeling) generally operate with a 3-axis linear positioning mechanism that carries a heated extruder through a path in three dimensions. As the extruder travels it dispenses molten or softened plastic supplied as a filament on a spool. The filament is welded sequentially in a growing surface on a build platform.

The machines in the Digifab Shop at Artisans Asylum are all benchtop units that produce plastic parts. Plastic filaments are supplied by the shop, though users are permitted to supply their own.

These tools are RED tools. Users must be trained and tool-tested before they are permitted to operate them.

Pages in category "3D Printers - Extrusion"

The following 7 pages are in this category, out of 7 total.