Category:3D Printers - Extrusion: Difference between revisions

Acharlwood (talk | contribs) m (Fixed broken category link) |

Acharlwood (talk | contribs) (A subcategory with only one entry doesn't need to be a subcategory (yet)) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Tools]] | |||

{{ToolBox | {{ToolBox | ||

| Line 12: | Line 11: | ||

|manufacturer_specs = | |manufacturer_specs = | ||

|manual = | |manual = | ||

|location = Digifab | |location = Digifab Shop | ||

|rubric = | |rubric = | ||

|training = | |training = | ||

| Line 85: | Line 84: | ||

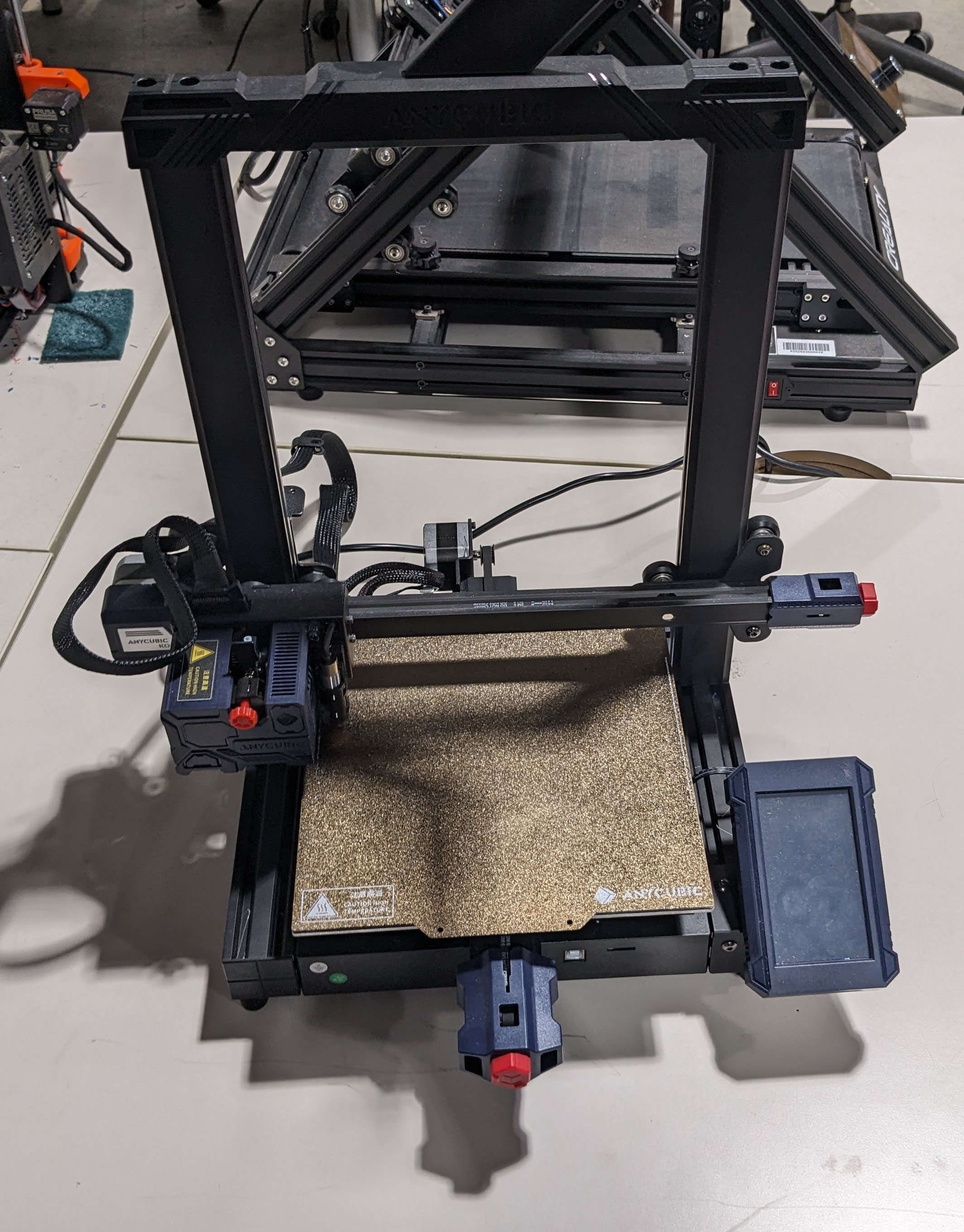

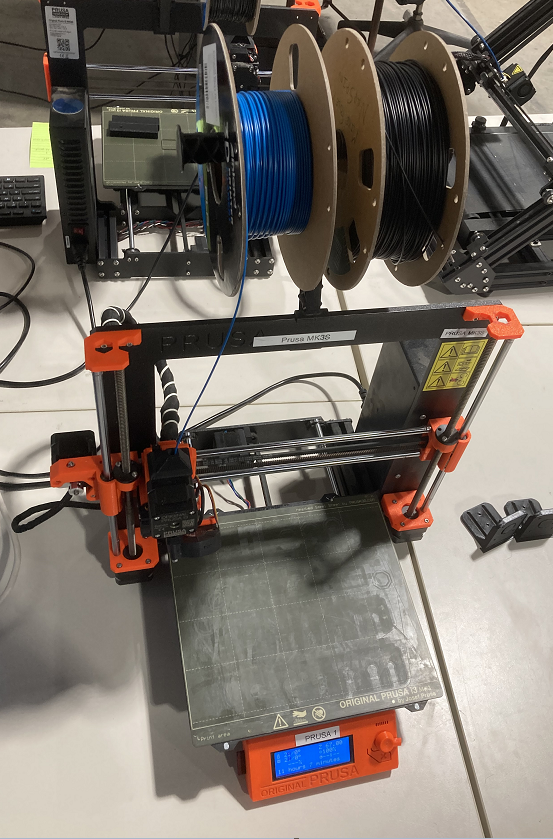

| [[File:anyKubicKobra.jpg|180px]] || [[File:Prusa.png|150px]] || [[File:MarkforgedM2.jpg|220px]] || [[File:SynDaver_AXI2.png|120px]] | | [[File:anyKubicKobra.jpg|180px]] || [[File:Prusa.png|150px]] || [[File:MarkforgedM2.jpg|220px]] || [[File:SynDaver_AXI2.png|120px]] | ||

|} | |} | ||

Latest revision as of 12:33, 22 August 2024

| FDM Printers | |

|---|---|

| General Info | |

| Make | various |

| Model | |

| Serial | |

| Specs | |

| Manual | |

| Asylum Info | |

| Location | Digifab Shop |

| Rubric | |

| Training | |

| Testing | |

| Restrictions | red |

Description

3D printers in general consist of a robot with a material dispenser attached to it. The user sends digital data to the printer that encodes a shape to be built. The machine then executes a program that dispenses material in a pattern that coincides with the desired shape. Additionally the machine may also create ancillary structures to support the shape during the build job. After the part is built, it is removed from the machine and may be subjected to various post-processing operations to finish it.

Extrusion-type 3D printers (Also called FDM for Fused Deposition Modeling) generally operate with a 3-axis linear positioning mechanism that carries a heated extruder through a path in three dimensions. As the extruder travels it dispenses molten or softened plastic supplied as a filament on a spool. The filament is welded sequentially on a growing surface on a build platform.

The machines in the Digifab Shop at Artisans Asylum are all benchtop units that produce plastic parts. Plastic filaments are supplied by the shop, though users are permitted to supply their own.

These tools are RED tools. Users must be trained and tool-tested before they are permitted to operate them.

Safety

FDM three dimensional printers are generally considered to be safe for the user as long as certain precautions are followed.

- Do not touch the extruder nozzle. It operates at 200-300 C (400-580 F) and can cause serious burns on the skin.

| |

|---|---|

- Allow 20 minutes for the heater to cool after switching off the power.

- Don't touch recently extruded plastic.

- Hot plastic can emit irritating odors.

- The heated bed can operate around 100 C (212 F). This is hot enough to cause burns if the skin is pressed against it.

- Don't reach inside the printer mechanism while it is operating. Keep fingers away from moving mechanical components.

- Be careful with sharp edges on scraping tools. Never push the blade towards your hand.

| |

|---|---|

- Wear safety goggles when cleaning or sanding parts.

- Keep loose clothing and long hair away from moving parts.

- Always wear closed-toe shoes at Artisans Asylum.

Machines

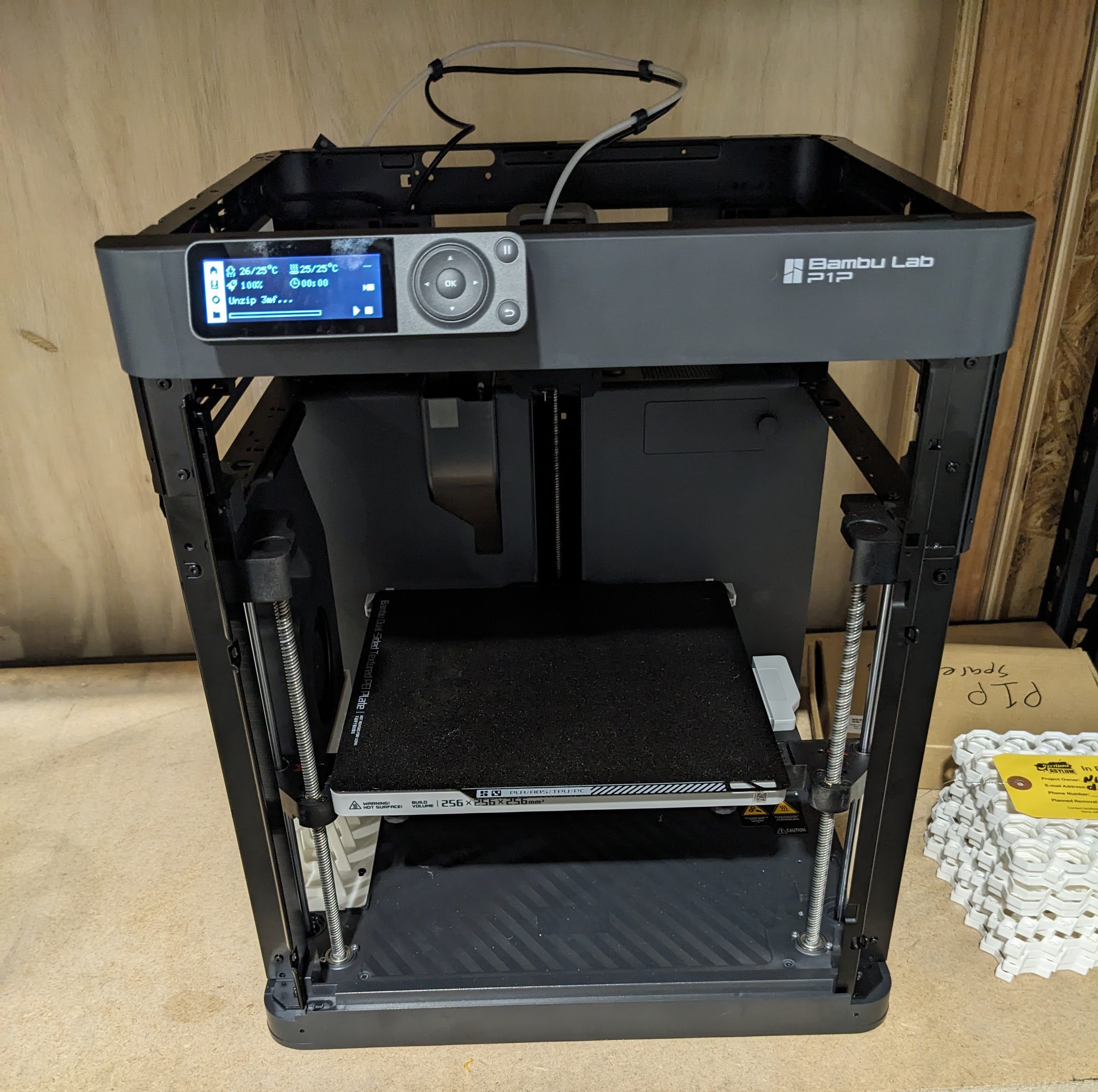

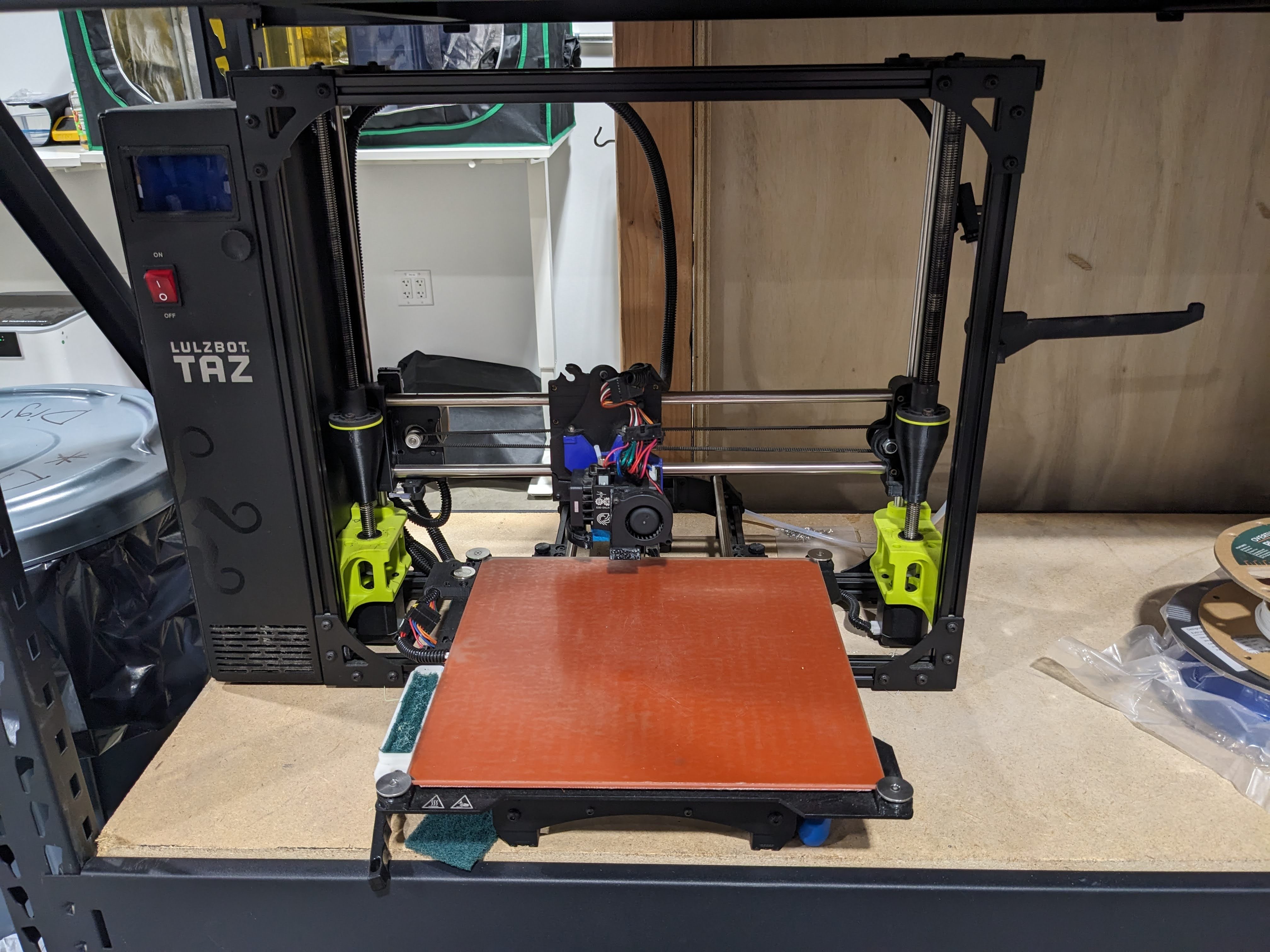

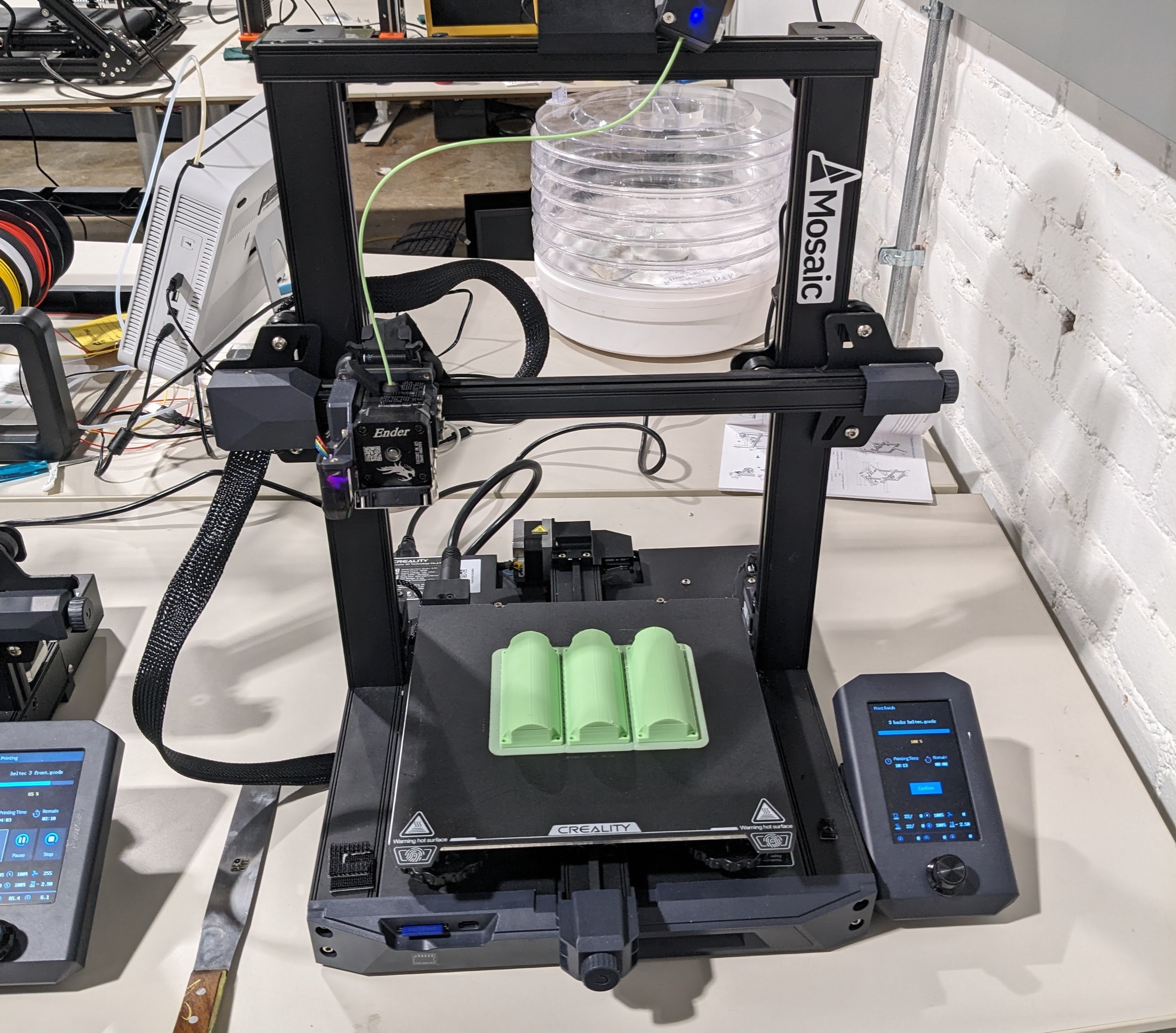

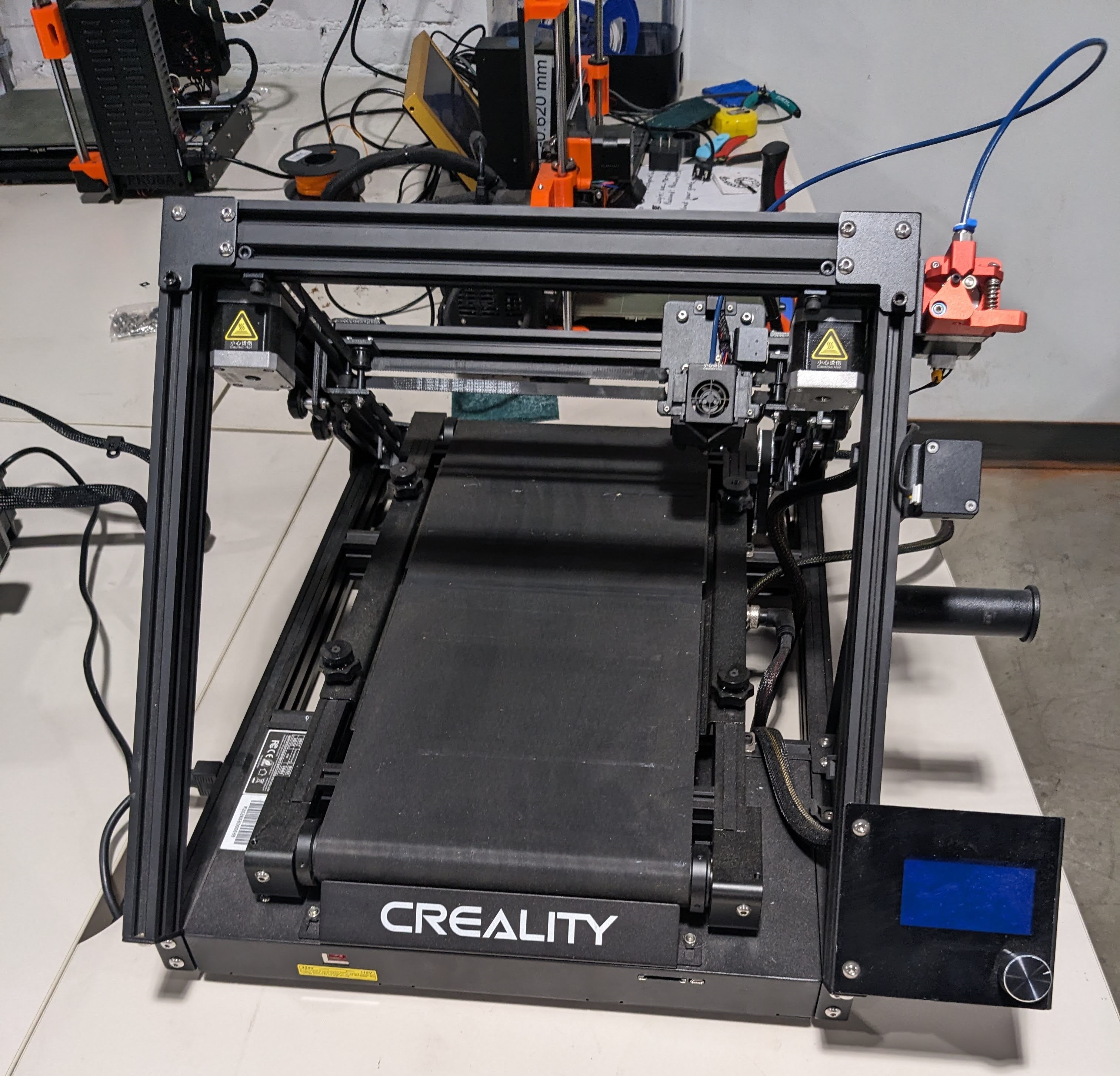

| BambuLabs P1P | LulzBot Taz6 | Ender 3S1 (2 units) | Creality Ender CR-30 |

|---|---|---|---|

|

|

|

|

| anyCubic Kobra | Prusa MK3 (2 units) | Markforged Mark 2 | SynDaver Axi 2 |

|---|---|---|---|

|

|

|

|

Pages in category "3D Printers - Extrusion"

The following 7 pages are in this category, out of 7 total.