3D Printer Prusa MK3: Difference between revisions

| Line 25: | Line 25: | ||

=Description= | =Description= | ||

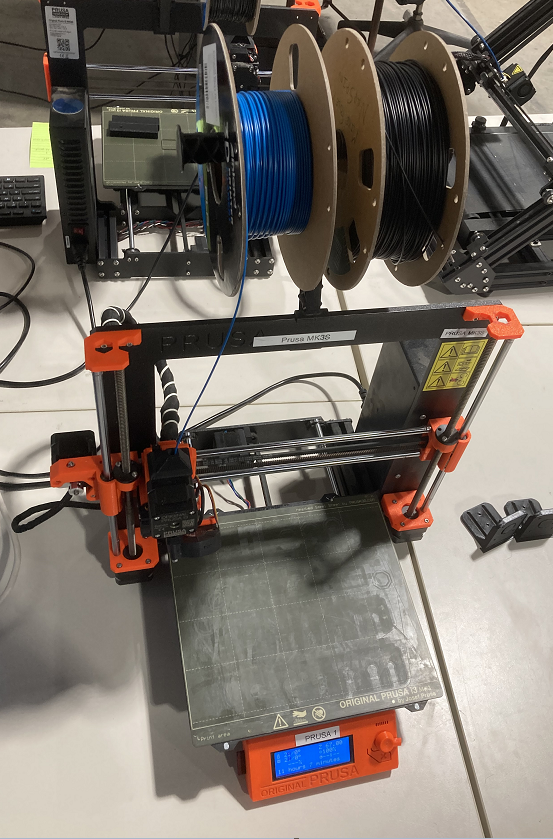

The Prusa printers are real workhorses, and with a little care are very reliable. The two MK3 machines we have have these features: | |||

* Filament sensor | |||

* Power Panic | |||

* RPM sensing fans and Noctua | |||

* Ambient thermistor and P.I.N.D.A 2 with thermistor | |||

* EINSY RAMBo motherboard | |||

* Trinamic2130 drivers with layer shift detection, faster and silent printing | |||

* Bondtech extruder | |||

* Magnetic MK52 Heatbed | |||

==Mechanical== | ==Mechanical== | ||

| Line 35: | Line 45: | ||

Much use of 3D printed parts in mechanism. | Much use of 3D printed parts in mechanism. | ||

== Basic use and maintenance == | |||

Please check that the print nozzle and the surrounding area are free of plastic from a previous print. Plastic there can drop onto your print and cause a printing failure. If there is a bit (or glob) of plastic, use the menu to pre-heat the hot end and wipe it clear with a cloth. Then proceed with your print. | |||

When printing PLA, the smooth magnetic sheet works well. If printing PET-G, use glue stick or blue tape on the magnetic sheet, as it will otherwise adhere too strongly to the sheet surface. For other materials, check whether preparation of the print surface is required. | |||

The magnetic sheet may be cleaned with isopropyl alcohol. If it has glue residue, you can wash it in warm water and dry it carefully. Finger prints can prevent your print from sticking, so handle the sheet by the edges after cleaning. | |||

Remove your print by lifting the magnetic sheet off the printer bed and (after it cools) flexing it to release the print. Avoid using metal spatulas or other tools that may damage the printing surface. | |||

Revision as of 10:49, 2 April 2024

Link to: Digifab Shop main page

| Prusa MK3 | |

|---|---|

| General Info | |

| Make | Josef Prusa |

| Model | MK3 |

| Serial | Unknown |

| Specs | |

| Manual | User Manual |

| Asylum Info | |

| Location | Digifab Shop |

| Rubric | |

| Training | |

| Testing | |

| Restrictions | red |

See the FDM category page for notes on using all extrusion-type 3D printers

Safety

Link to: Safety notes for all FDM printers

Description

The Prusa printers are real workhorses, and with a little care are very reliable. The two MK3 machines we have have these features:

- Filament sensor

- Power Panic

- RPM sensing fans and Noctua

- Ambient thermistor and P.I.N.D.A 2 with thermistor

- EINSY RAMBo motherboard

- Trinamic2130 drivers with layer shift detection, faster and silent printing

- Bondtech extruder

- Magnetic MK52 Heatbed

Mechanical

Stage: 200mm x 200mm; Y-motion; sliders on rods, belt drive.

Gantry: 2 screw-jacks, 2 steppers for Z; Belt drive sliders on rods for X

Extruder: 1.75mm; proximity sensor.

Much use of 3D printed parts in mechanism.

Basic use and maintenance

Please check that the print nozzle and the surrounding area are free of plastic from a previous print. Plastic there can drop onto your print and cause a printing failure. If there is a bit (or glob) of plastic, use the menu to pre-heat the hot end and wipe it clear with a cloth. Then proceed with your print.

When printing PLA, the smooth magnetic sheet works well. If printing PET-G, use glue stick or blue tape on the magnetic sheet, as it will otherwise adhere too strongly to the sheet surface. For other materials, check whether preparation of the print surface is required.

The magnetic sheet may be cleaned with isopropyl alcohol. If it has glue residue, you can wash it in warm water and dry it carefully. Finger prints can prevent your print from sticking, so handle the sheet by the edges after cleaning.

Remove your print by lifting the magnetic sheet off the printer bed and (after it cools) flexing it to release the print. Avoid using metal spatulas or other tools that may damage the printing surface.