Cyclone Sand Blaster: Difference between revisions

| Line 289: | Line 289: | ||

! colspan="2" class="infobox-image" | [[File:blaster_hopper_drain_4.jpg|200px|drain 4]] | ! colspan="2" class="infobox-image" | [[File:blaster_hopper_drain_4.jpg|200px|drain 4]] | ||

|- | |- | ||

| colspan="2" | Open the hatch. | | colspan="2" | Open the hatch, part way at first to begin opening, then fully to get all of the media out. | ||

|- | |- | ||

|} | |} | ||

| Line 305: | Line 305: | ||

|} | |} | ||

The media hoppers are to be emptied and the media sifted after each use. In a shared facility it's important that each user have access to good clean media, and is not blasting with media contaminated by rust and remnants from the previous user's project. | |||

The latches holding the hopper hatches closed are supported by a magnetic brace helping hold the latch in place. Always replace these to support the latch. | |||

Use a tray to collect the media, then sift into the proper "In-Use" bucket. | |||

Use a tray to collect the media | |||

=Adding Media to the Hopper= | =Adding Media to the Hopper= | ||

Open the hatch on the side of the blast cabinet and pour the media into the hopper. | Open the hatch on the side of the blast cabinet and pour the media into the hopper. | ||

Revision as of 23:40, 12 July 2024

Link to: Metal Shop main page

| Sand Blaster | |

|---|---|

| General Info | |

| Make | Cyclone Manufacturing |

| Model | DW-7335 (obsolete) |

| Serial | Unknown |

| Specs | |

| Manual | link= Manual for a similar model |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | |

| Training | Tool classes |

| Testing | Tool testing, or [[:Category:Metal Shop#Tool Testing

Night|come to the shop on Tool Testing Night]] |

| Restrictions | RED |

| |

|---|---|

| |

|---|---|

| |

|---|---|

| Eye protection required! | ||

|---|---|---|

Description

A sand blaster is a machine that mixes abrasive grains with a jet of compressed air and allows the user to abrade the surface of a part, usually metal. This results in a clean though roughened part free of paint, rust, and other forms of dirt. The blast gun is contained in a steel cabinet sealed off from the outside. The user manipulates the tool with thick rubber gloves that pass through the wall of the cabinet.

The sand blaster cabinet at Artisans Asylum is located in a small room within the Metal Shop on the south wall adjacent to the fenced-in outdoor porch.

Sand blasting is the LAST stage, not the first, in cleaning a part and preparing the surface for finishing.

Do not use the sandblaster to clean heavily rusted pieces. This would be a slow, inefficient way to do that and is likely to clog and damage the equipment. After testing for lead, remove surface rust with wire brushes, manually or with a power tool attachment. Only then is the piece ready for sandblasting.

NOTE: "Sandblasting" is a misnomer. NEVER use actual sand in a blasting process.

Use For

- Steel

- Stainless Steel

- Zinc-coated steel (Galvanized)

- Aluminum, Titanium, Brass

- Painted metal - abrade with wire brush or sandpaper first

- Lightly Rusted Parts after initial cleaning

Do Not Use For

- Lead-based paints

- Asbestos

- Greasy or Oily Parts

- Massively Rusty Parts

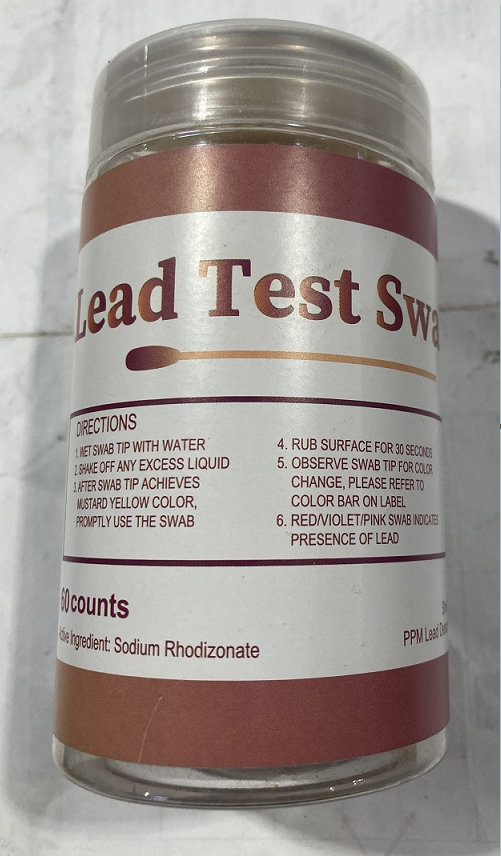

Use a lead-test swab to verify that paint is NOT lead-based!

If the sandblaster becomes contaminated with lead the media must be disposed as TOXIC WASTE and the cabinet must be thoroughly cleaned out!

Personal Safety

| |

|---|---|

- NEVER use silica sand as an abrasive media. Always use media designated for blast use.

- Test paints and coatings for LEAD using the test swabs provided. The swabs change from yellow to red when lead is present. If lead is detected do not clean with the sand blaster.

- Wear safety goggles. Eyeglasses don't protect against abrasive dust.

- Wear respirator or N95 or better mask when using the machine or working in the room when the machine is being used. All fine dust is hazardous to breathe.

- Place the workpiece in the blast cabinet and close the hatch tightly to avoid dust escaping from the cabinet. Check that doors on both ends are latched close along with both hoppers. When removing workpieces, some dust will unavoidably mix with the room air. Wear a dust mask at all times when working in sand blast room.

- Cabinet gloves and viewing window are at a fixed height above the floor. If they are too high, a stand should be provided. Use care on unstable stands.

- If the blast gun is not properly grounded to the cabinet, static electricity can cause shocks to the operator. If static shocks are encountered, check the ground connection to the gun.

- Use caution when lifting heavy parts into the sandblaster cabinet.

- If a part is too large to allow the hatch to close and seal, do not operate the sandblaster.

- Use caution with the foot pedal and hoses. Place them where the trigger cannot be accidentally depressed when the hoppers or cabinet are open.

Shop and Equipment Care

- EMPTY THE SAND BLASTER CABINET OF USED MEDIA AFTER EVERY USE. Sift used media into provided bucket matching the type of media you are using, and dispose of filtered waste in trash. Do not leave machine full of used media. Do not "top-off" with clean media in hoppers with used media. If media is too spent to use effectively, discard and start with fresh media. Mixing new media with partially spent media wastes media and makes an ineffective blast medium.

- Shop standard media is brown aluminum oxide. If using alternate media, such as glass or ceramic beads, empty cabinet and thoroughly clean rails etc. inside the cabinet, both before and after using this media.

- Do not abrade greasy or oily parts in the sandblaster. These can cause the media to clump and clog the flow lines, and damage the equipment.

- Do not move the blast cabinet when it is full of abrasive media.

- Do not point the blast gun at the rubber gloves or the cabinet window or the cabinet ceiling light.

How to Prepare Metal Workpieces for Blasting

* TEST FOR LEAD.

| |

|---|---|

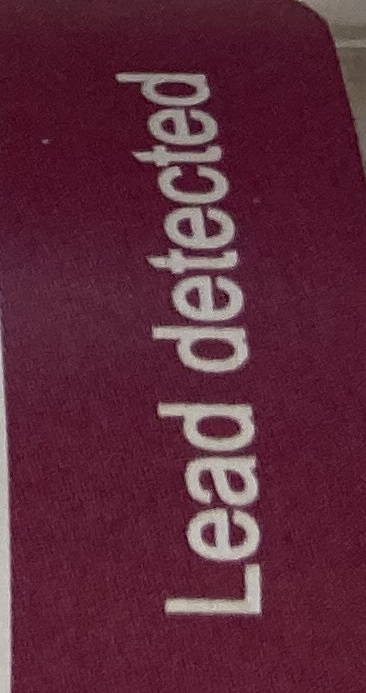

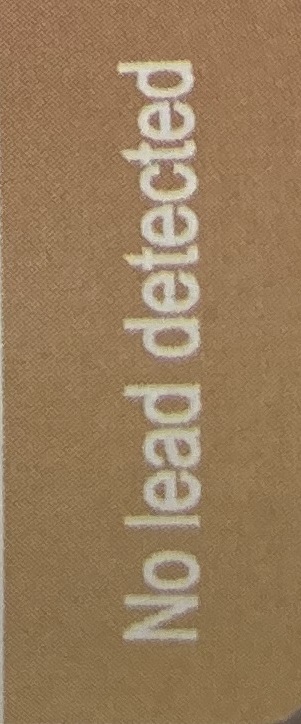

| Color if lead is present |

| |

|---|---|

| Color for no lead |

| |

|---|---|

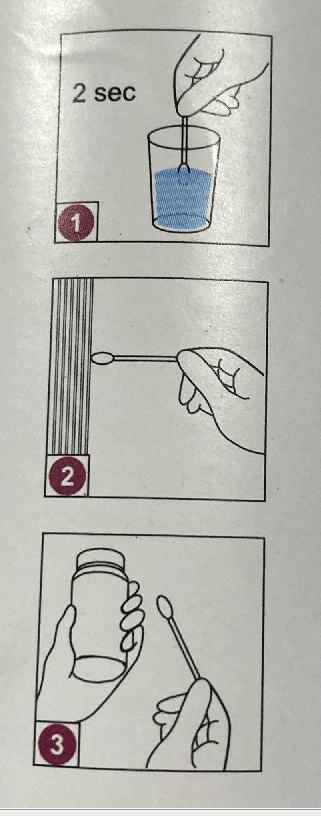

| How to Swab |

| |

|---|---|

| Lead test swabs |

Lead and lead paint are forbidden on this machine. Use a lead test swab to verify that there is no lead on the surface of your workpiece.

Moisten the tip with water, wait 2 seconds for the reagent to dissolve, then rub the surface.

If no lead is present the swab stays yellow-orange. It turns crimson if lead is present.

If the machine becomes contaminated with lead, tell the facilities manager so that the media can be safely disposed. It is toxic waste. It is not legal to throw the media away yourself. The blast cabinet must be scrubbed to remove toxic dust.

* Clean off any massive rust with a grinder before placing the workpiece in the sandblaster.

Large flakes of rust can mix with the blasting media and clog the flow lines leading to the gun.

* Degrease the workpiece

If greasy or oily, clean the workpiece with a solvent or a water-base cleaner such as Simple Green. Make sure it is dry before placing it in the blast cabinet.

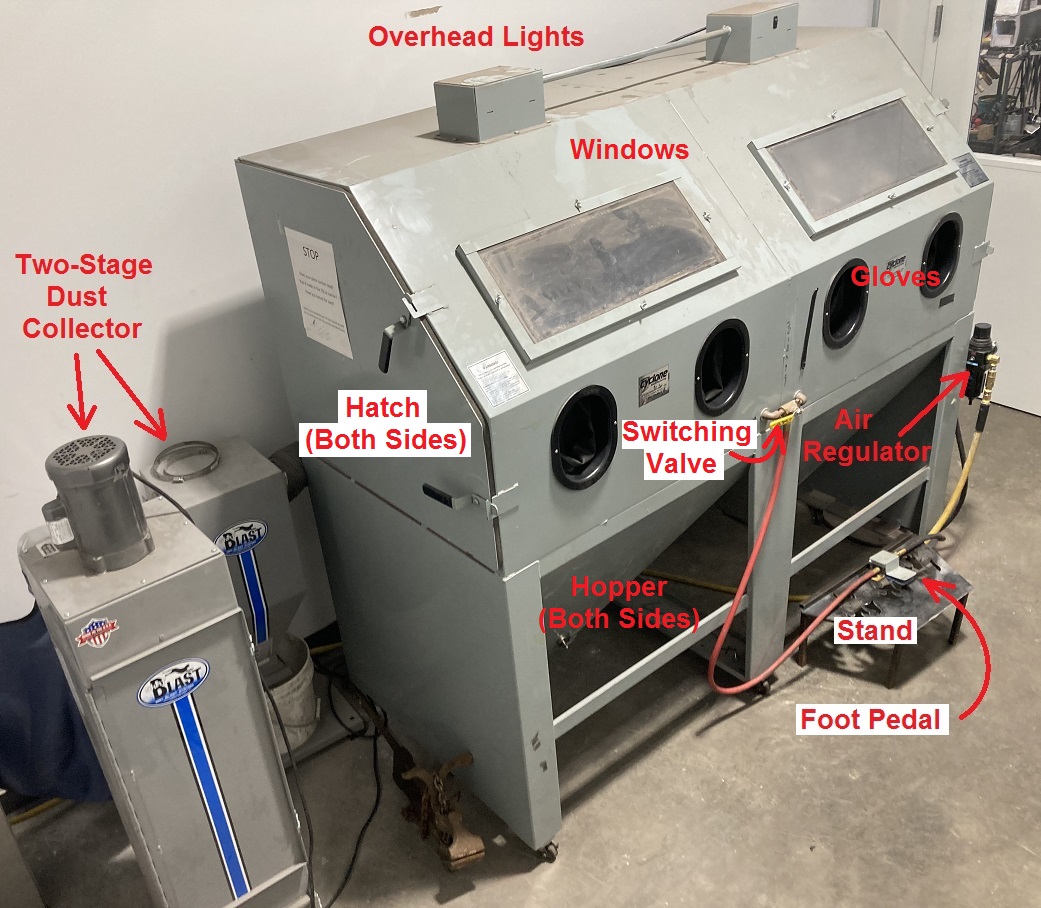

Parts of the Sandblaster

| |

|---|---|

| The Sandblaster and dust collector installation |

The sand blasting room has ventilation to the outside. Before beginning to work turn this on at the timer-switch, located on the wall next to the CNC plasma cutter.

The sandblaster has three free-standing components: The cabinet is the largest, and the others are the compents of the two-stage dust collector to the left of the cabinet.

The sandblaster is equipped with two different kinds of nozzle, one in each bay, with a valve on the front to determine which one is in use. The shop does not have enough air pressure to run both at once.

Turn on the dust collector by plugging it and the air filter into the outlet on the left.

Turn on the cabinet lights with the small switch on right hand box.

The sandblasting action is controlled with the foot pedal on the floor or stand. Always stay aware of the placement of the foot pedal so it's not accidentally triggered.

Operation Notes

| |

|---|---|

| The power switch for the sanblast room ventilator is located around the corner on the back wall adjacent to the CNC plasma cutter. |

1. Ensure that the air compressor is on. It is located in a closet in the loading dock area.

2. Turn on the room ventilator. Switch located in the CNC Plasma area.

3. Put on goggles and a dust mask or respirator.

4. Check the air pressure at the regulator on the blaster cabinet. Target pressure is 60 - 100psi

5. Plug in the two-stage air filter at the end of sand blaster room, and cabinet if that's not already plugged in.

6. Check that the media hoppers were emptied by the last user. If they were not, it is highly recommended to empty and sift the media before beginning.

7. Add media to the hopper where you intend to work, pouring it through the grate in the cabinet. The correct amount of media is between 10 and 20 lbs, depending on the media. Too much media will compact in the hopper can clog the feed hose. Make sure the feed tube is down in the media.

- Asylum uses brown aluminum oxide for our standard media; use 3 - 5 quarts (yogurt container scoops)

- glass bead media is also available for member use

- use ONLY media intended for blasting use. NEVER use actual, silica sand.

8. Place the workpiece in the cabinet and latch the hatch shut. Confirm that the doors on both ends of the cabinet are latched, as well as both hoppers.

9. Arrange the stand as/if needed and place the foot pedal in a convenient spot. Be careful of tippy step-stand.

8. Turn on the cabinet light switch on top right of the cabinet. Optionally, also shut off room light for better visibility into the cabinet.

9. Stick hands into rubber gloves, grasp blasting gun and step on the foot pedal to BLAST!!!

- If no media appears to be coming out, and no abrasion is happening, check valve lever on front of cabinet.

- While the air is flowing, it may be necessary to wiggle the dip tube that reaches down into the hopper where the media is located.

- After a long period working, the media may migrate from the hopper in use to the hopper not in use. Simply place bakers tray under opposite hopper, open to collect media, close, and pour the tray back into the hopper in use. BE CAREFUL WHEN DOING THIS to stay always aware of the foot pedal location, so as not to accidentally trigger it while the cabinet is open.

- Open the cabinet and inspect your work periodically. Wait a minute or two for the dust to settle before opening the hatch.

10. When finished, place bakers tray under the hopper, empty the media out of the machine and carefully pour through the sifter back into the proper "in-use" bucket. Empty both hoppers as media will have migrated during use.

12. Sweep loose media off the floor. Loose media is a respiratory hazard and can create a slip hazard. Remove used paper towel, gloves etc., from room; empty dust pan and waste from sieve into trash can in main metal shop.

- If using any media other than the shop-standard aluminum oxide, you must thoroughly clean the cabinet when you are finished. Remove metal grates and use a broom to clean the rails inside the cabinet. When using shop standard media, emptying the hoppers and sifting is sufficient cabinet clean-up.

| |

|---|---|

| Flakes can block the gun and damage the hoses. |

| |

|---|---|

| Pour the media through the screen provided to remove flakes. |

| |

|---|---|

| The total quantity of media in the hopper should be 10 - 20 lbs, or 3 - 5 quarts in volume of aluminum oxide media. |

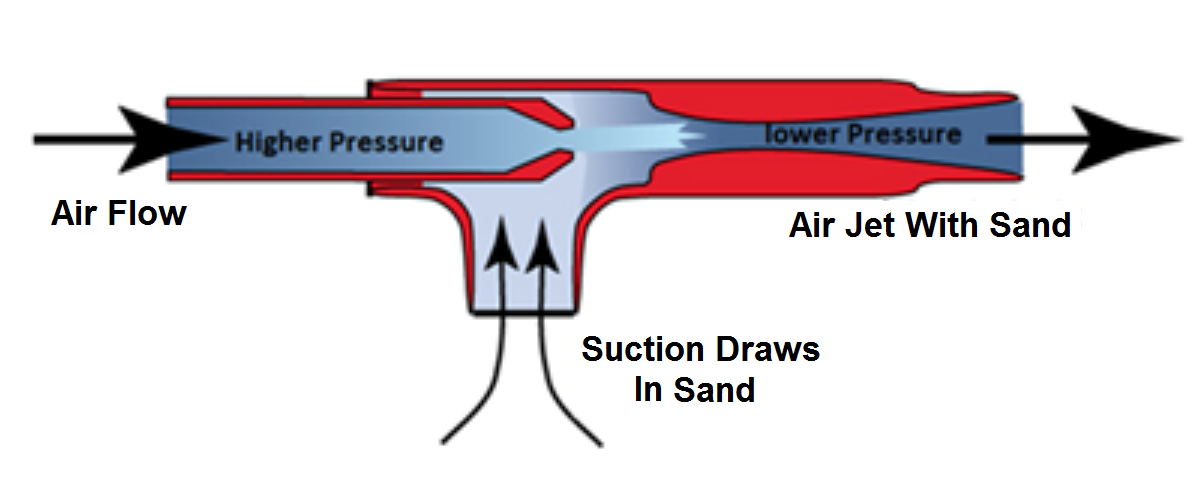

How it Works

The sandblasting gun is a pneumatic device called a Venturi. Compressed air is fed into the end of the gun and issues through the nozzle. Inside the gun the air jet traverses a side entry that is connected to a dip tube that reaches into the pile of media in the hopper.

The jet of air from the high pressure side entrains slower-moving air in the side entry, causing it to be drawn up through the dip tube. Feeding 100 psi air from the air supply results in 2-5 psi of suction at the dip tube.

| |

|---|---|

| The blast gun with hose connections. Top: High pressure air feed; Middle Right: Blast Gun; Left: Suction hose with dip tube. |

| |

|---|---|

| A schematic view of the blast gun. |

The suction in the dip tube collects media from the hopper and feeds it into the air jet. Aluminum oxide has a density almost double that of glass. Excessive media in the hopper will cause it to compress in the lower portions and make it unflowable.

The correct amount of aluminum oxide media for reliable operation is about 1 gallon, roughly 15 lbs.

If there is too much media in the hopper it is necessary to agitate the dip tube to keep the media flowing up to the gun. This can make the process seem like a three-handed job at times if you need to use a hand to steady the workpiece.

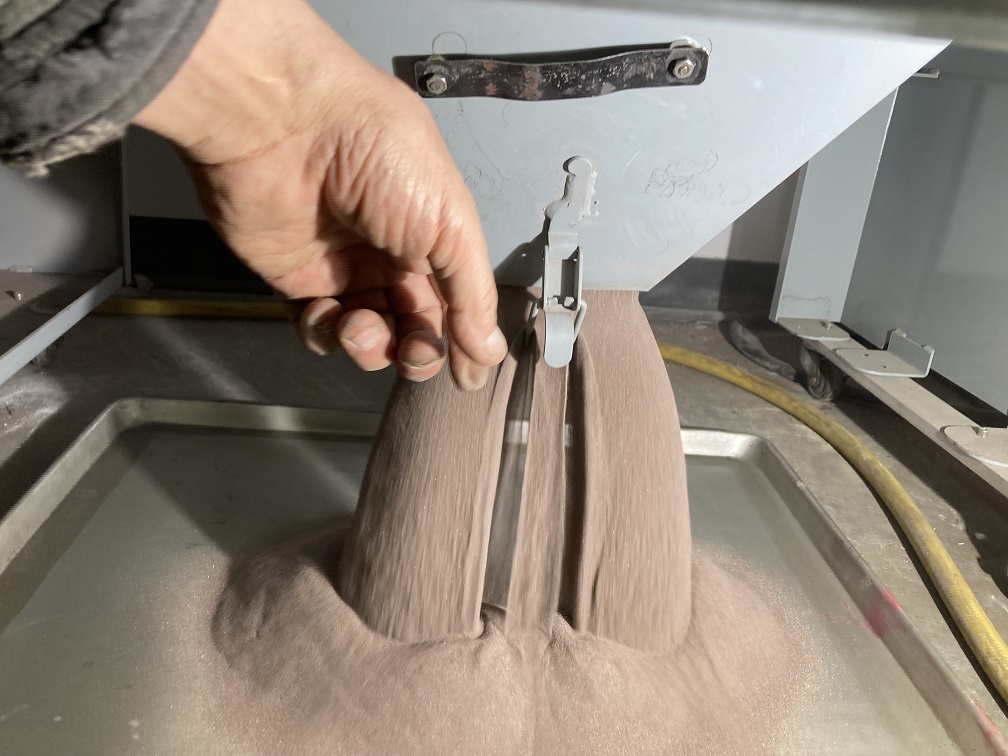

Draining Media from the Hopper

| |

|---|---|

| Open the hatch, part way at first to begin opening, then fully to get all of the media out. |

| |

|---|---|

| Grasp the latch. |

| |

|---|---|

| Move the magnetic brace. |

The media hoppers are to be emptied and the media sifted after each use. In a shared facility it's important that each user have access to good clean media, and is not blasting with media contaminated by rust and remnants from the previous user's project.

The latches holding the hopper hatches closed are supported by a magnetic brace helping hold the latch in place. Always replace these to support the latch.

Use a tray to collect the media, then sift into the proper "In-Use" bucket.

Adding Media to the Hopper

Open the hatch on the side of the blast cabinet and pour the media into the hopper.