Brackets Tutorial 3: No Frills Shelf Bracket: Difference between revisions

No edit summary |

No edit summary |

||

| Line 15: | Line 15: | ||

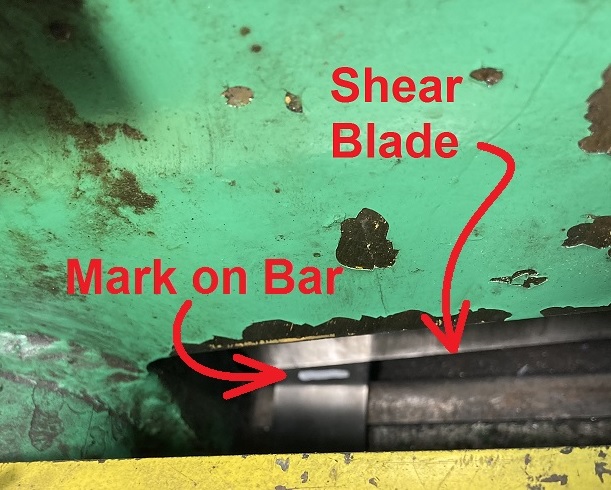

Insert the bar and line up the cut line with the blade of the Ironworker shear. | Insert the bar and line up the cut line with the blade of the Ironworker shear. | ||

[[File:Tut3_Bracket_nofrills_marking_the_blank.jpg| | [[File:Tut3_Bracket_nofrills_marking_the_blank.jpg|670px|marking]] | ||

[[File: | [[File:SW_gear_icon_tiny.png|10px|thin strip]] | ||

[[File: | [[File:Tut3_Bracket_nofrills_setting_blank_in_IW.jpg|220px|bar_in_shear]] | ||

Tigthen down the stock clamp. Depress the foot pedal on the Ironworker to bring the shear blade down. | Tigthen down the stock clamp. Depress the foot pedal on the Ironworker to bring the shear blade down. | ||

Revision as of 22:11, 15 September 2024

Link to: Bracketage Main Page

Introduction

This document shows a very simple process for making a right-angle shelf bracket. It uses mostly GREEN tools that don't require any training. The dimensions are 6" x 6" x 1-1/4" but the reader will see that these dimensions are arbitrary.

Cut the blank

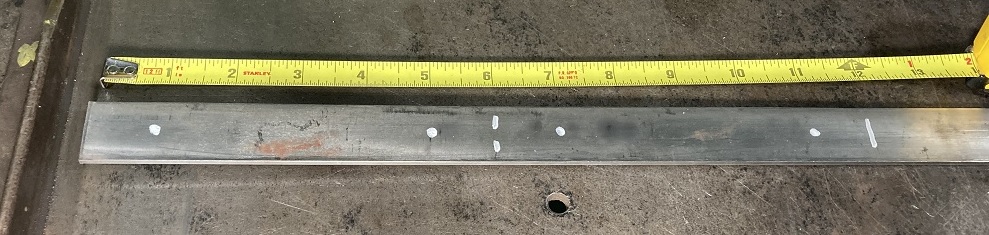

We use 1-1/4" x 1/8" steel strip and cut it on the Ironworker. Mark the overall length of the bar and the line where it should be bent with a highly visible marker. Put dots where the mounting holes will go.

Turn on the power to the Ironworker so the blade rises to the top of its travel.

Insert the bar and line up the cut line with the blade of the Ironworker shear.

Tigthen down the stock clamp. Depress the foot pedal on the Ironworker to bring the shear blade down.

Release the foot pedal as soon as the bar is cut! DO NOT allow the Ironworker to bottom out!

Punch the Mounting Holes

Now we punch the mounting holes in the blank.

Turn off the power to the Ironworker.

Select the punch and die set for 1/4" holes. Note that the die for 1/4" holes is 1/32" larger in diameter: 9/32". Tools for tightening the punch and die are provided in the tool box.

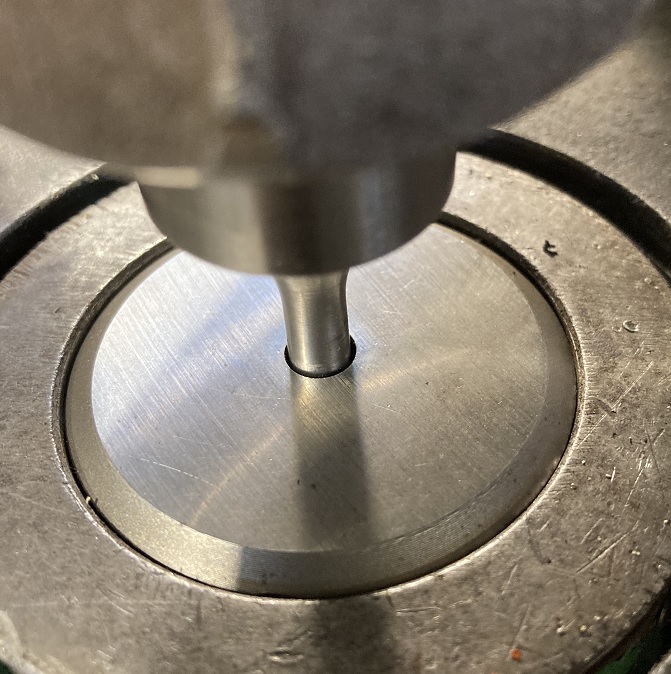

Place the die in the die seat on the punch table with the small hole facing up. Tighten with the hex wrench provided.

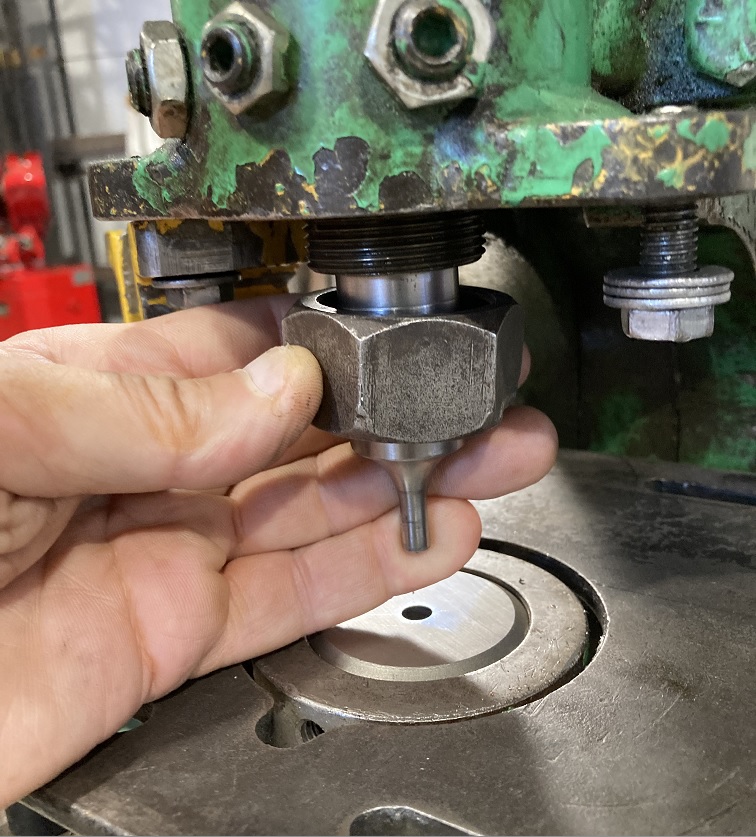

Insert the punch into the punch socket and tighten the nut only finger tight prior to aligning it.

Grab the handle at the top of the punch spindle and pull it down to lower the punch into the die.

Make sure the punch is centered in the hole in the die. Push it around by hand until it is centered

Tighten the punch with the wrench provided and then return the handle to its top position.

Swing the upper part of the stripper into position.

Place the lower part of the stripper underneath it.

Place the workpiece under the stripper and lower the punch to line it up with the mark.

Depress the foot pedal to bring the punch down.

Release the foot pedal as soon as the hole is punched! DO NOT allow the Ironworker to bottom out!

Place the workpiece under the stripper. Lower the punch again to line up the workpiece with the punch.

Repeat the process until all of the holes are punched.