Brackets Tutorial 3: No Frills Shelf Bracket: Difference between revisions

| Line 159: | Line 159: | ||

To blast, point the gun at the workpiece and depress the foot pedal. | To blast, point the gun at the workpiece and depress the foot pedal. | ||

[[File:Tut3_Bracket_nofrills_blaster_media.jpg| | [[File:Tut3_Bracket_nofrills_blaster_media.jpg|260px|add media]] | ||

[[File:SW_gear_icon_tiny.png|5px|thin strip]] | [[File:SW_gear_icon_tiny.png|5px|thin strip]] | ||

[[File:SW_gear_icon_tiny.png|5px|thin strip]] | [[File:SW_gear_icon_tiny.png|5px|thin strip]] | ||

[[File:Tut3_Bracket_nofrills_blaster_hatch.jpg| | [[File:Tut3_Bracket_nofrills_blaster_hatch.jpg|250px|blaster hatch]] | ||

[[File:SW_gear_icon_tiny.png|5px|thin strip]] | [[File:SW_gear_icon_tiny.png|5px|thin strip]] | ||

[[File:SW_gear_icon_tiny.png|5px|thin strip]] | [[File:SW_gear_icon_tiny.png|5px|thin strip]] | ||

[[File:Tut3_Bracket_nofrills_blaster_window.jpg| | [[File:Tut3_Bracket_nofrills_blaster_window.jpg|240px|sandblast window]] | ||

Revision as of 23:32, 17 September 2024

Link to: Bracketage Main Page

Introduction

This document shows a very simple process for making a right-angle shelf bracket. It uses mostly GREEN tools that don't require any training. The dimensions are 6" x 6" x 1-1/4" but the reader will see that these dimensions are arbitrary.

Cut the blank

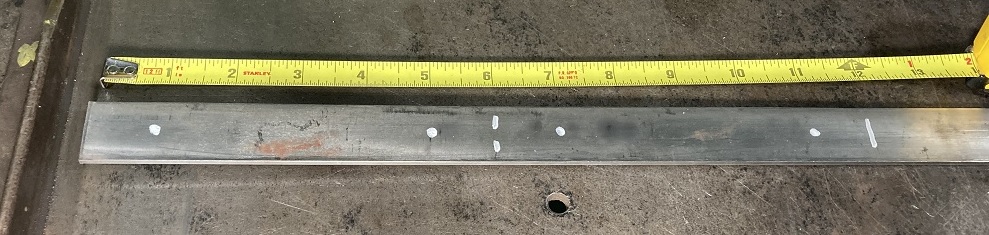

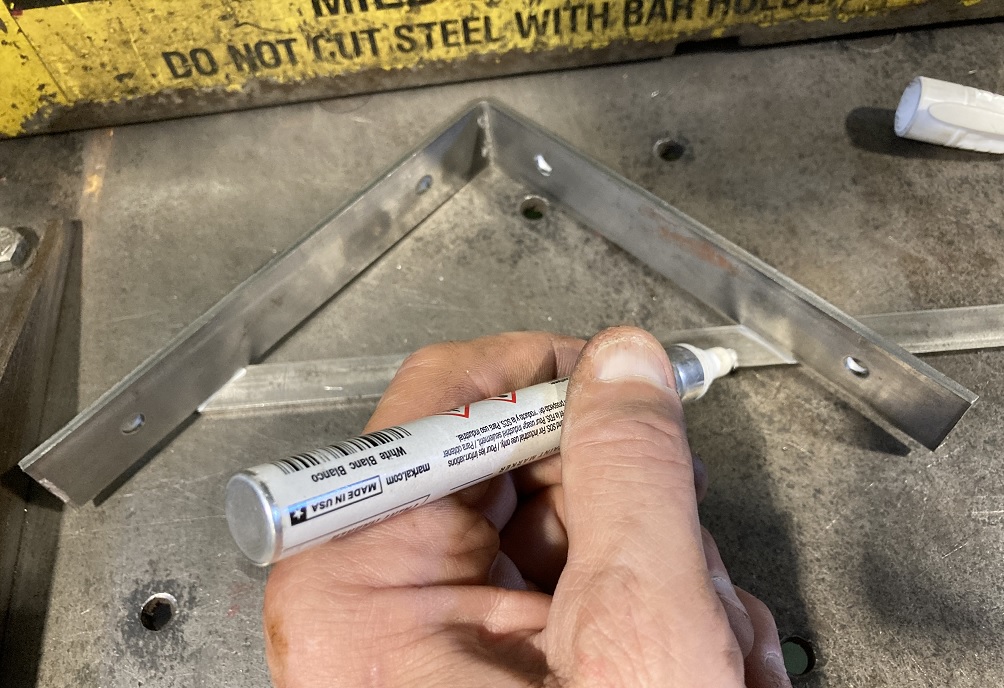

We use 1-1/4" x 1/8" steel strip and cut it on the Ironworker. Mark the overall length of the bar and the line where it should be bent with a highly visible marker. Put dots where the mounting holes will go.

Turn on the power to the Ironworker so the blade rises to the top of its travel.

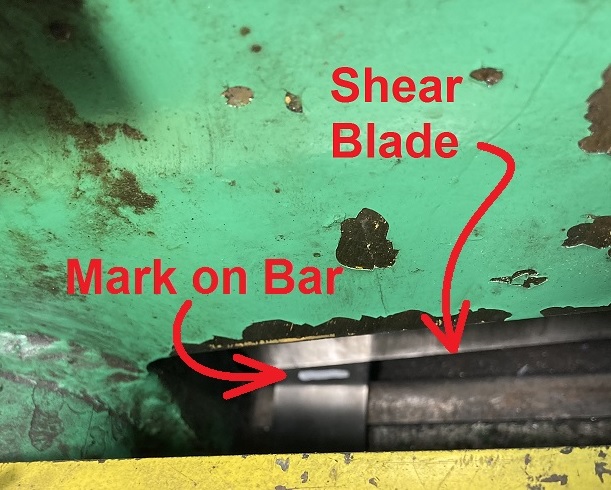

Insert the bar and line up the cut line with the blade of the Ironworker shear.

Tigthen down the stock clamp. Depress the foot pedal on the Ironworker to bring the shear blade down.

Release the foot pedal as soon as the bar is cut! DO NOT allow the Ironworker to bottom out!

Punch the Mounting Holes

Now we punch the mounting holes in the blank.

Turn off the power to the Ironworker.

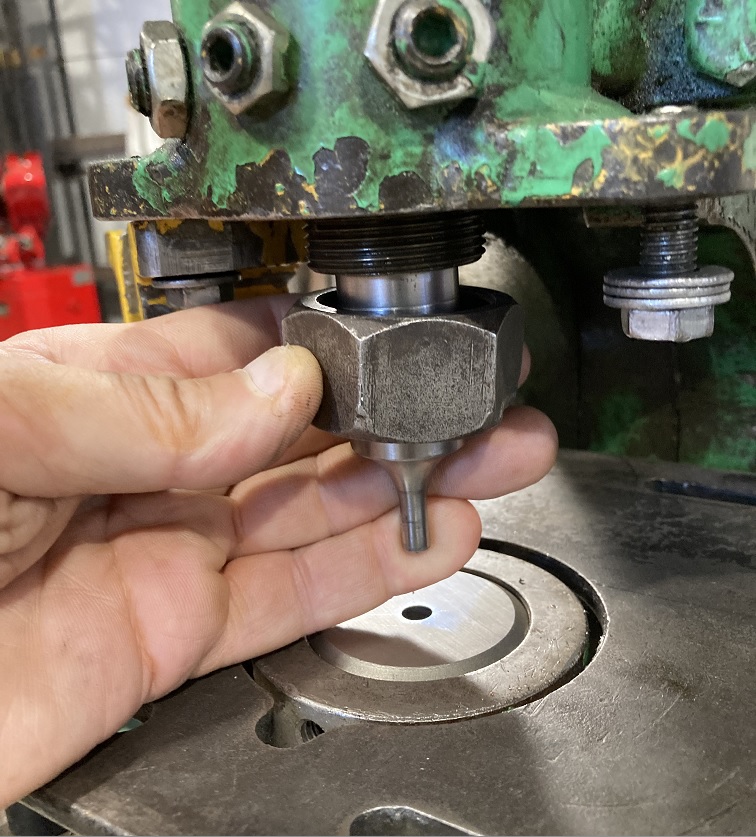

Select the punch and die set for 1/4" holes. Note that the die for 1/4" holes is 1/32" larger in diameter: 9/32". Tools for tightening the punch and die are provided in the tool box.

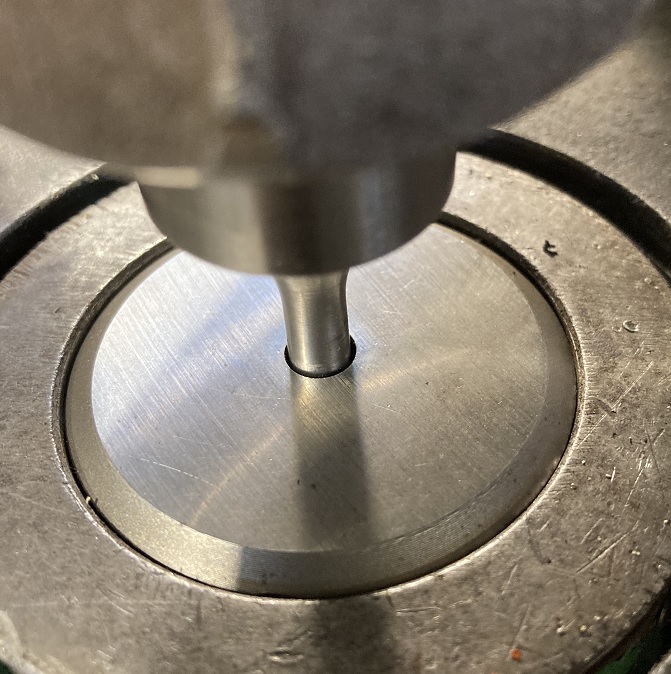

Place the die in the die seat on the punch table with the small hole facing up. Tighten with the hex wrench provided.

Insert the punch into the punch socket and tighten the nut only finger tight prior to aligning it.

Grab the handle at the top of the punch spindle and pull it down to lower the punch into the die.

Make sure the punch is centered in the hole in the die. Push it around by hand until it is centered

Tighten the punch with the wrench provided and then return the handle to its top position.

Swing the upper part of the stripper into position.

Place the lower part of the stripper underneath it.

Place the workpiece under the stripper and lower the punch to line it up with the mark. Return the release handle to the top position.

Depress the foot pedal to bring the punch down.

Release the foot pedal as soon as the hole is punched! DO NOT allow the Ironworker to bottom out!

Repeat the process until all of the holes are punched.

Bend the Bracket

This operation uses the Hydraulic Shop Press that can be found in the back of the shop near the chop saws.

Place the workpiece in the bending tool and lower the tool until it lightly presses against the workpiece.

Square up the workpiece in the tool and make sure the bend mark is under the tool.

Pump the press and bend the workpiece. Check the angle periodically to make sure it comes out with a right angle.

Cut and Weld the Diagonal Brace

To strengthen the bracket, we add a diagonal brace to the bracket. First we cut it on the Ironworker.

You can measure it, or you can place the bent piece on a piece of bar stock (in this case, 1/2" x 1/8") and mark it. Try to account for the width of the pen tip.

You can insert bar stock at an angle into the Ironworker. Clamp as normal and chop.

Assemble the angle brace to the bracket on the welding bench. As shown it is held up with welding magnets.

Weld the brace to the bracket with a MIG welder.

The MIG welder is a RED tool. You must be trained and tool-tested in order to use this tool.

Cleaning

Before finishing the bracket, we will use the sand blaster to clean off oxide and slag residue from the welding process.

This is a RED tool. You must be trained and tool-tested in order to use this tool.

Before working in either the sand-blaster room or the powder-coating room, you MUST don goggles and a dust mask.

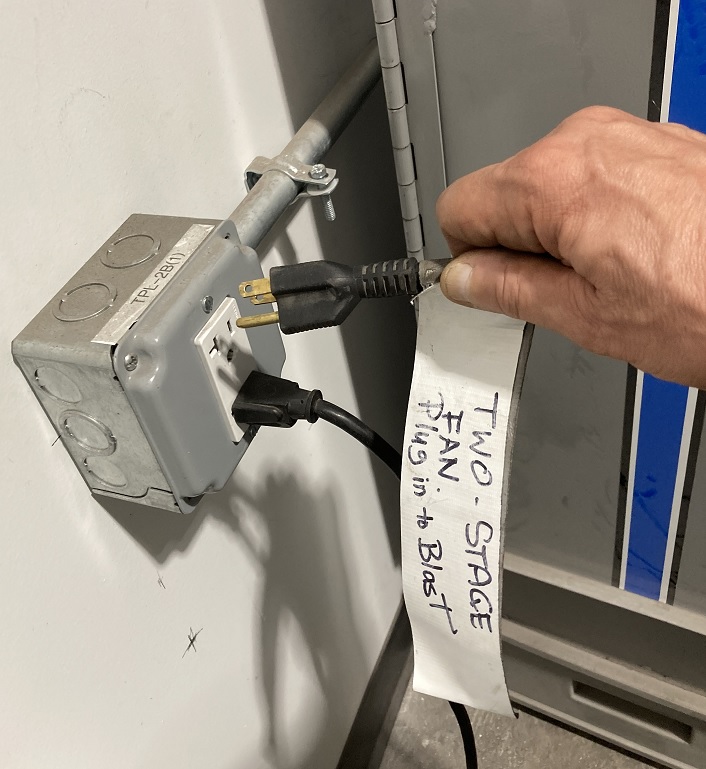

Plug in the two-stage dust collector located in the back of the sand-blaster room.

Also switch on the room ventilation fan located adjacent to the CNC plasma cutter.

IF the hopper is empty, add media to the cabinet. Don't add too much. There should only be about 2 quarts of media in the hopper.

Place the workpiece into the sand-blaster cabinet and seal the door shut.

To blast, point the gun at the workpiece and depress the foot pedal.