General Hydraulic Shop Press: Difference between revisions

No edit summary |

|||

| Line 38: | Line 38: | ||

{| class="infobox" cellspacing="5" style="width: 12em; text-align: left; font-size: 100%; line-height: 1.5em;" | {| class="infobox" cellspacing="5" style="width: 12em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

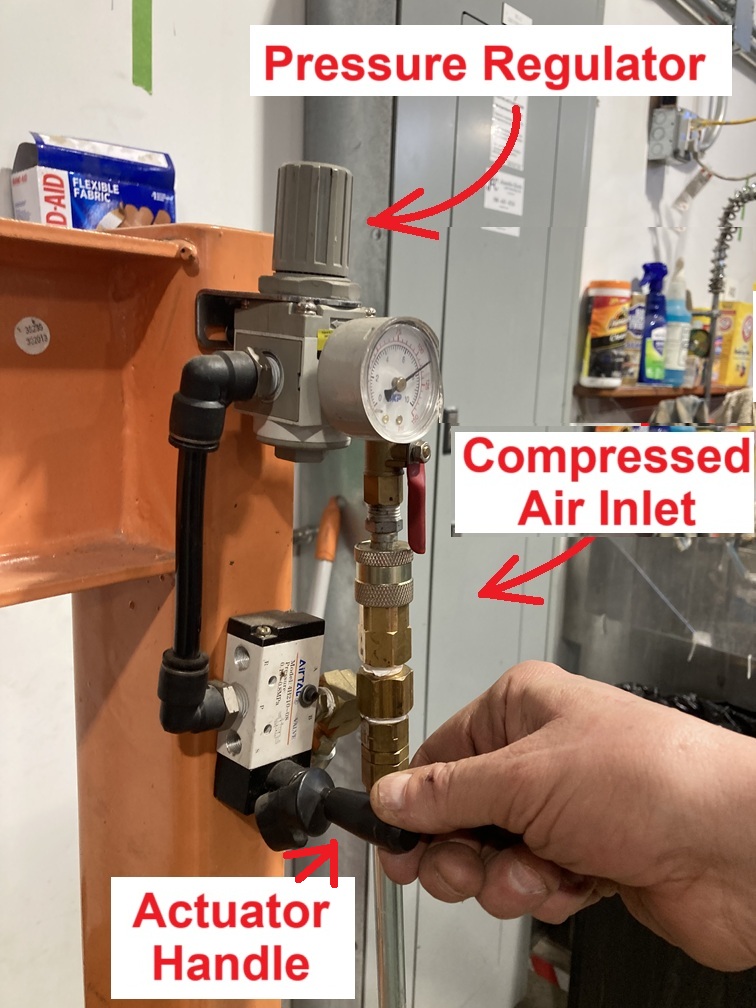

! colspan="2" class="infobox-image" | [[File:Pneumatic_control_labeled.jpg|200px| | ! colspan="2" class="infobox-image" | [[File:Pneumatic_control_labeled.jpg|200px| pneumatic control]] | ||

|- | |- | ||

| colspan="2" | The compressed-air inlet and control | | colspan="2" | The compressed-air inlet and control | ||

Revision as of 11:53, 22 February 2025

Link to: Machine Shop Main Page

| Hydraulic Shop Press | |

|---|---|

| General Info | |

| Make | General Hydraulic |

| Model | 20-ton |

| Serial | |

| Specs | |

| Manual | Pittsburgh 20-ton Bottle Jack Manual |

| Asylum Info | |

| Location | Machine Shop |

| Rubric | N/A |

| Training | |

| Testing | Tool testing |

| Restrictions | green |

Description

A hydraulic jack mounted to a frame that translates the lifting force into pressure. Built around a Pittsburgh 20-ton bottle jack. Width: 18 inches. Also includes a jig for bending metal sheet. It has a compressed-air actuator built in but can also be operated manually.

Use For

Squashing things

Do Not Use For

Not squashing things

Air Assist

The pneumatic control for the press is located at the top right corner of the frame. You will need to run a hose over from the shop or from the CNC plasma cutter around the corner.

| |

|---|---|

| The compressed-air inlet and control |

Bending Accessory

| |

|---|---|

| The bending jig for the 20-ton shop press |

This accessory normally rests on the floor behind the press. Caution! Weight is about 60 lbs.

It is constructed over a piece of 3" x 3" x 5/16" angle, so the bends it makes are distributed through about 4" of width. To tighten up the bend radius, stack pieces of smaller angle inside the large one.

Loads to bend steel sheet can be found on this tonnage chart. Do not exceed 20 tons.