Logan Manual Lathe

Link to: Machine Shop Main Page

| Eye protection required! | ||

|---|---|---|

| Logan Lathe | |

|---|---|

| General Info | |

| Make | Logan |

| Model | |

| Serial | |

| Specs | |

| Manual | Instructions |

| Asylum Info | |

| Location | Machine Shop |

| Rubric | N/A |

| Training | |

| Testing | Tool testing |

| Restrictions | red |

See the Lathes category for notes on using all lathes

Link to: Parts List

Link to: Instructions

Safety

Link to: Safety notes on the Metal-cutting lathes category page

Do not attempt to use this machine unless you have been properly trained and tool-tested.

Changing the spindle speed

The Logan lathe has mechanical variable speed adjustment. This has a continuous range instead of discrete belt positions, but for the adjustment to work properly, the lathe must be running when you adjust the speed. With the lathe powered on, turn the handwheel on the stand until the speed dial shows the desired speed. The speed dial has two speed ranges; the lower speed range shows the spindle speed in back gear, and the higher speed range shows the spindle speed in high gear.

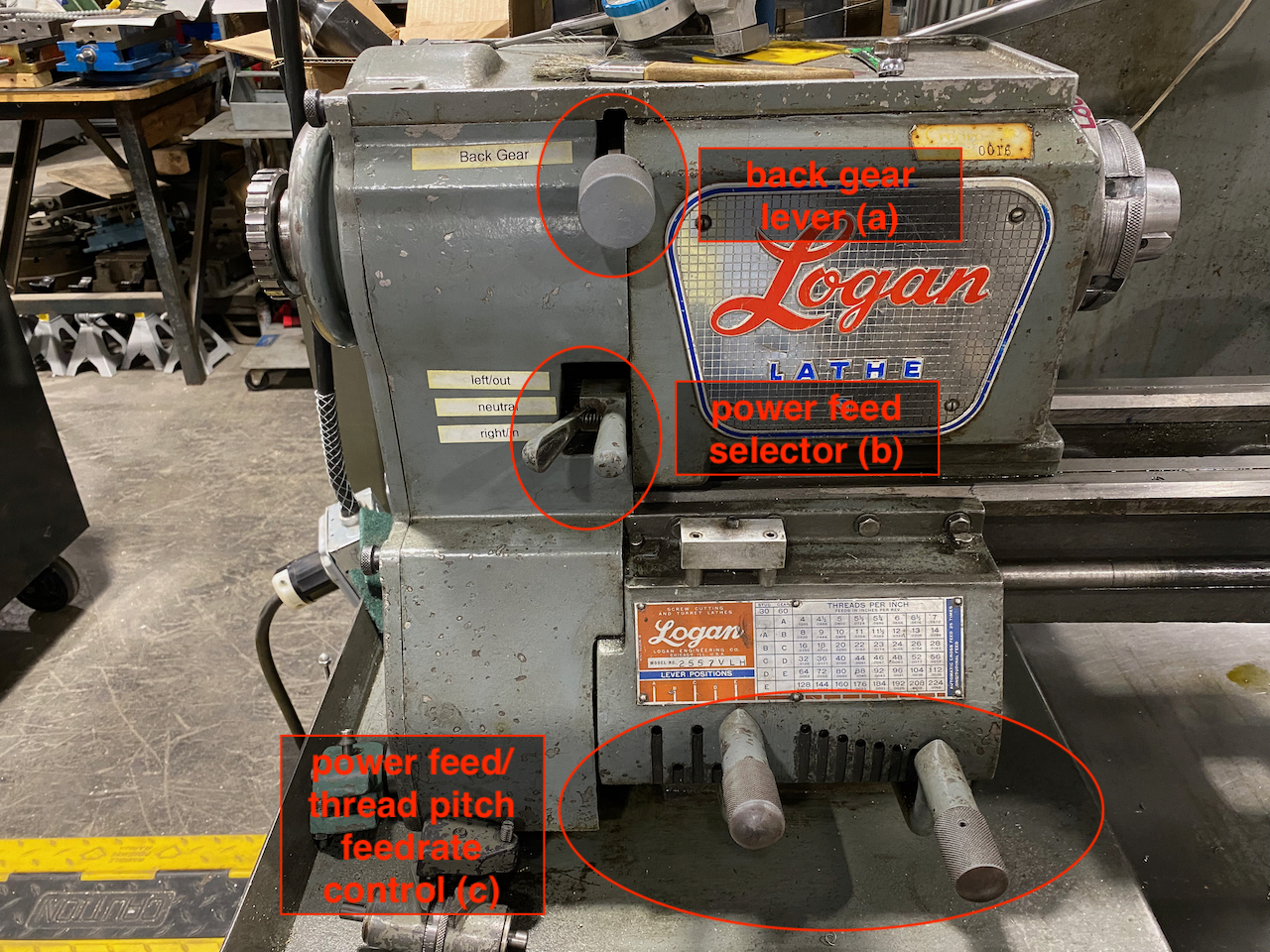

Back Gear

Like the South Bend, the Logan has a back gear to allow low speed, high torque spindle rotation. To put the Logan into back gear, pull the spindle clutch collar away from the headstock to disengage the clutch dogs. Then, lift the back gear lever up and pull it towards you until the lever clicks into place. Reverse these operations to go back into high gear; Lift the back gear lever and push it into the machine. Next, re-engage the spindle clutch collar by pushing it towards the headstock, making sure to align the clutch dogs.

Back gear creates additional mechanical, gear-meshing noise. Again, this noise is normal, but grinding or rubbing noises are not, so stop the lathe if you hear something unusual.

You can also lock the spindle by engaging back gear without disengaging the spindle clutch collar. This is useful for installing and removing chucks, but it will cause belts to rub and quickly wear if you try to operate the lathe in this condition.

Power Feed

The Logan has both power carriage feed and power cross feed. The keyway in the leadscrew powers this power feeding, so the leadscrew must be enabled to use power feed. With the lathe powered off, enable the power feed by moving the power feed lever out of the neutral position and into the appropriate direction. Note that turning and facing operations typically require different power feed lever settings.

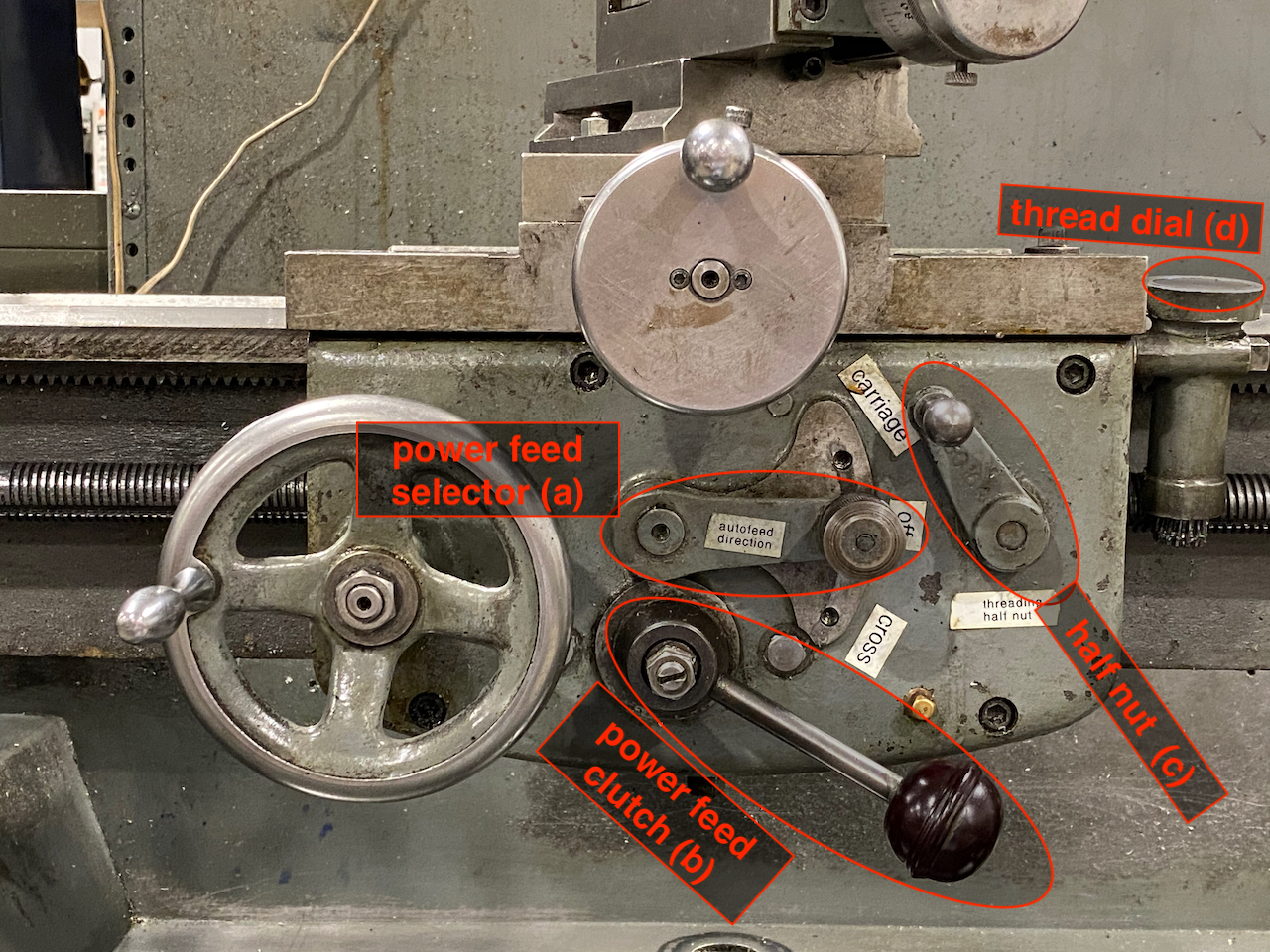

[picture of power feed lever and clutch on the apron]

With the lathe still powered off, move the power feed lever on the apron to the appropriate setting. Disengage the power feed by pushing the clutch lever on the apron down before turning on the lathe. Engage power feed by lifting the clutch lever up, and confirm that the correct feed knob is turning in the correct direction.

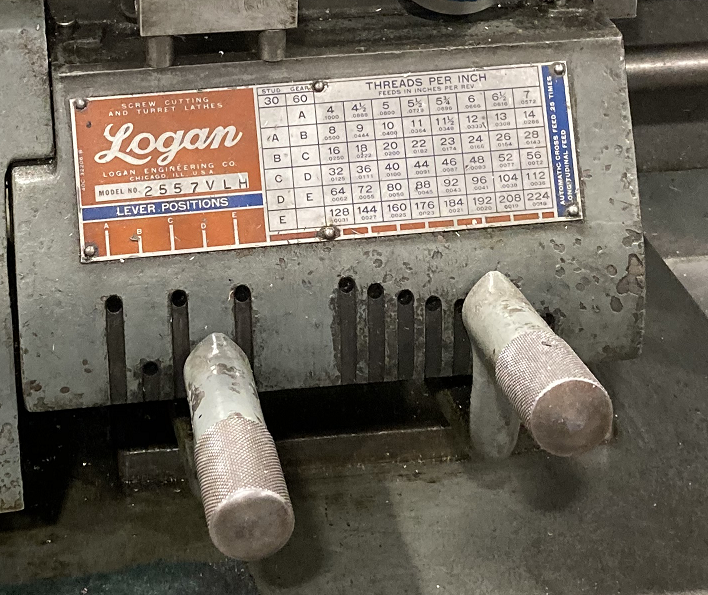

Two levers control the speed of the power feed. The leftmost position of these levers is the fastest feed speed, while the rightmost position is the slowest. Position E has a good range of feed rates, and this is typically the right setting for the first lever.

Operating Instructions

Lever type collet closer instructional set-up video.

Thread Turning

| |

|---|---|

| The threading gear controls on the Logan lathe |

This lathe features a traditional set of controls for turning threads.