Antwerp Shop Air

| Kaiser Air Compressor | |

|---|---|

| General Info | |

| Make | Kaiser |

| Model | |

| Serial | |

| Specs | n/a |

| Manual | |

| Asylum Info | |

| Location | Antwerp East Entry |

| Rubric | n/a |

| Training | |

| Testing | |

| Restrictions | green |

Description

This is a screw-type air compressor that is sized for the whole building. Presently it is only connected to the Metal Shop and the Machine Shop. Branches in the Metal Shop supply feed the Plasma Shop, the Sand Blaster, and the Powder Coating Facility. Supply pressure is about 100 psi. It has an automatic desiccator between the compressor and accumulator.

There is a copper manifold that spans the whole building, but it needs troubleshooting. Until this is done, connections are made ad-hoc and the compressor is only turned on when it is needed.

How To Turn It On

| |

|---|---|

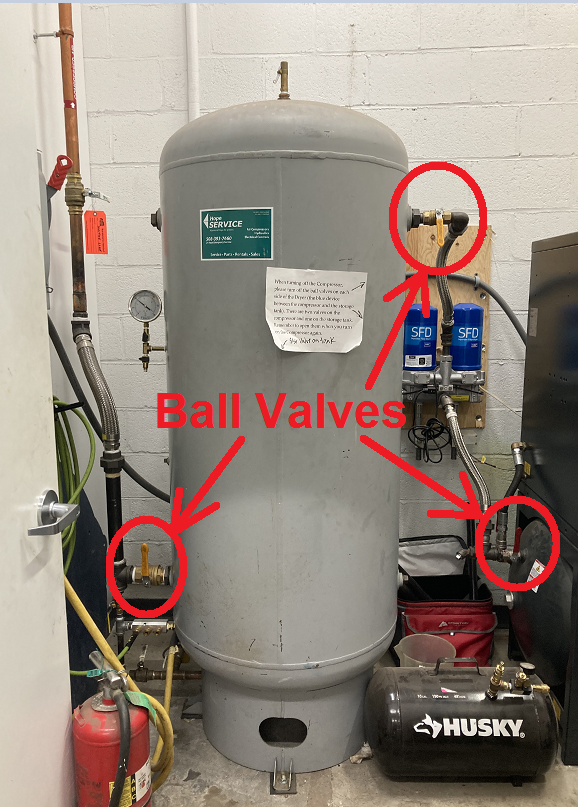

| These three valves must be OPEN to use the compressor. |

| |

|---|---|

| The compressor closet is located in the Antwerp loading dock entry, between the emergency exit and the utility closet. |

1. Find the closet. The light switch is inside, to the left of the door.

2. Don some hearing protection. The next step is LOUD

3. Open the three ball valves that control the air supply. Expect a loud "WHOOOSH." Two other valves are clearly labeled NOT to change.

| |

|---|---|

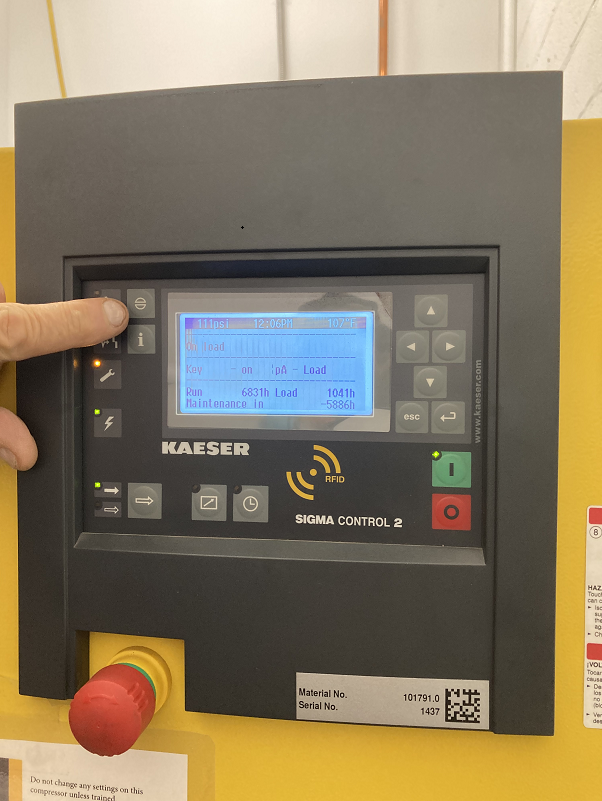

| Press the GREEN button to start. |

Note: To open a ball valve turn the handle so it is parallel to the pipe passing through it.

4. Walk around the right side of the compressor unit and find the "front" panel.

5. Press the green "ON" button to start the compressor.

6. Allow a few minutes for the air pressure to reach its control level.

How To Turn It Off

If you were the one who turned the machine on, then you should turn it off when you are finished, unless there are other users.

If there are other users, inform them before you leave that they are responsible for shutting off the air compressor.

| |

|---|---|

| Press the RED button to stop. |

1. Close the three ball valves illustrated above.

2. Go around the machine and press the red "OFF" button.

3. Close the door and turn off the light.

Troubleshooting

The most frequent problem is caused by opening the ball valves after the compressor has been started. The pressure transient will throw an error in the machine controller, and it will stop running.

To clear the error, press the button with the (![]() ) symbol.

) symbol.

If this procedure fails to clear the error, please send an email to <facilities@artisansasylum.com> to report the error.

| |

|---|---|

| Press this button to clear the error state. |