Fusion Tutorial 1c: Design of an Electronic Box, Continued

Link to: CAD Main Page

Link to: Tutorial 1b (prev)

Link to: Tutorial 1d (next)

Introduction

This tutorial is the third in a series teaching basic Fusion CAD sketching and modeling tools.

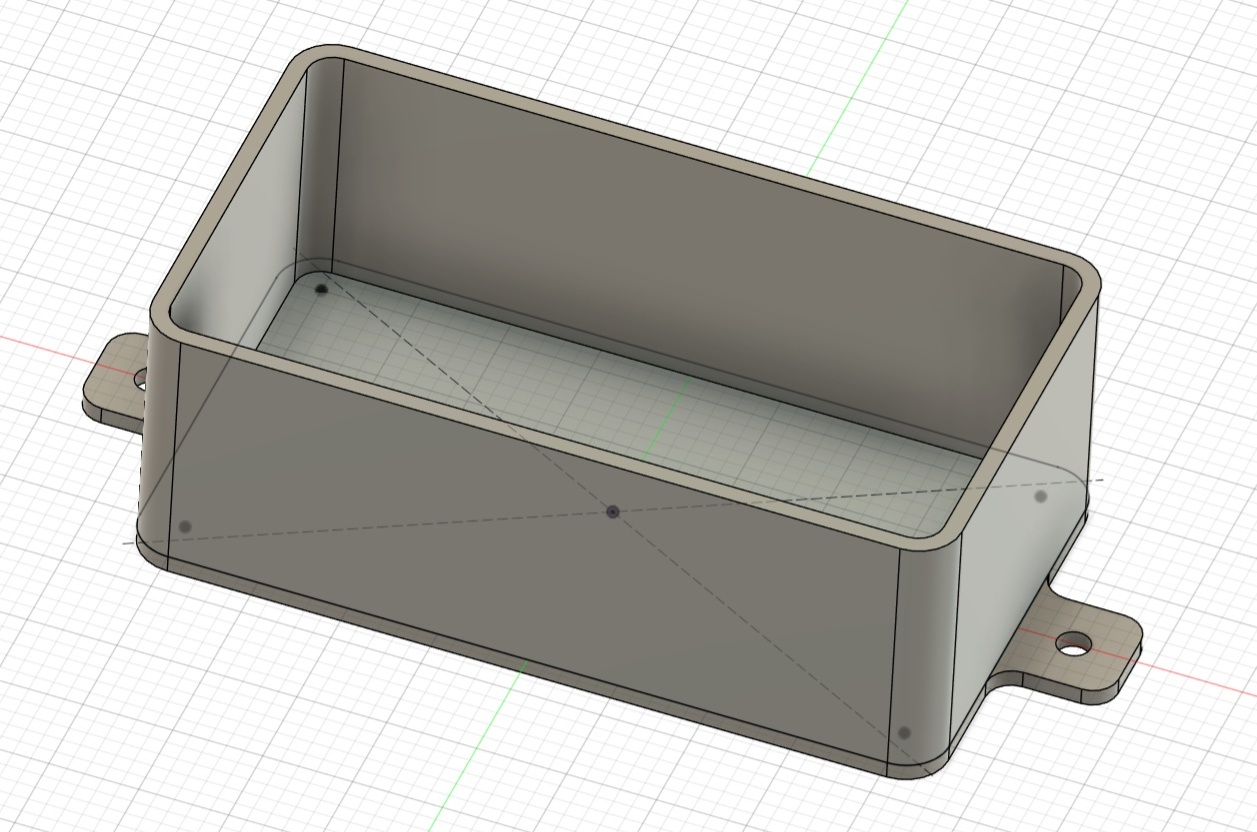

In the previous tutorial, we took the design a simple hollow box and added mounting features to it, using some parametric design tools available in Fusion. In this tutorial we will continue to add the features that will give the box its function: A sample electronics enclosure that could be made on a 3D printer.

In this tutorial we will add some more mounting features for attaching a lid to the box, and for mounting a circuit board inside the box. For the most part the tools used will be the same as those used in the previous tutorial, except we will introduce cutting of the solid using the (![]() ) "Extrude" tool, as well as copying and pasting sketch features in multiple places.

) "Extrude" tool, as well as copying and pasting sketch features in multiple places.

This tutorial is paced somewhat faster than the previous ones because it is assumed you've had some practice with the sketching and modeling tools in Fusion.

Design Mounting Lugs for a Lid

This operation is comprised of tasks that have been covered previously. These are features needed in the design, but it is presented as a sort of warm-up exercise.

Sketch the Lugs

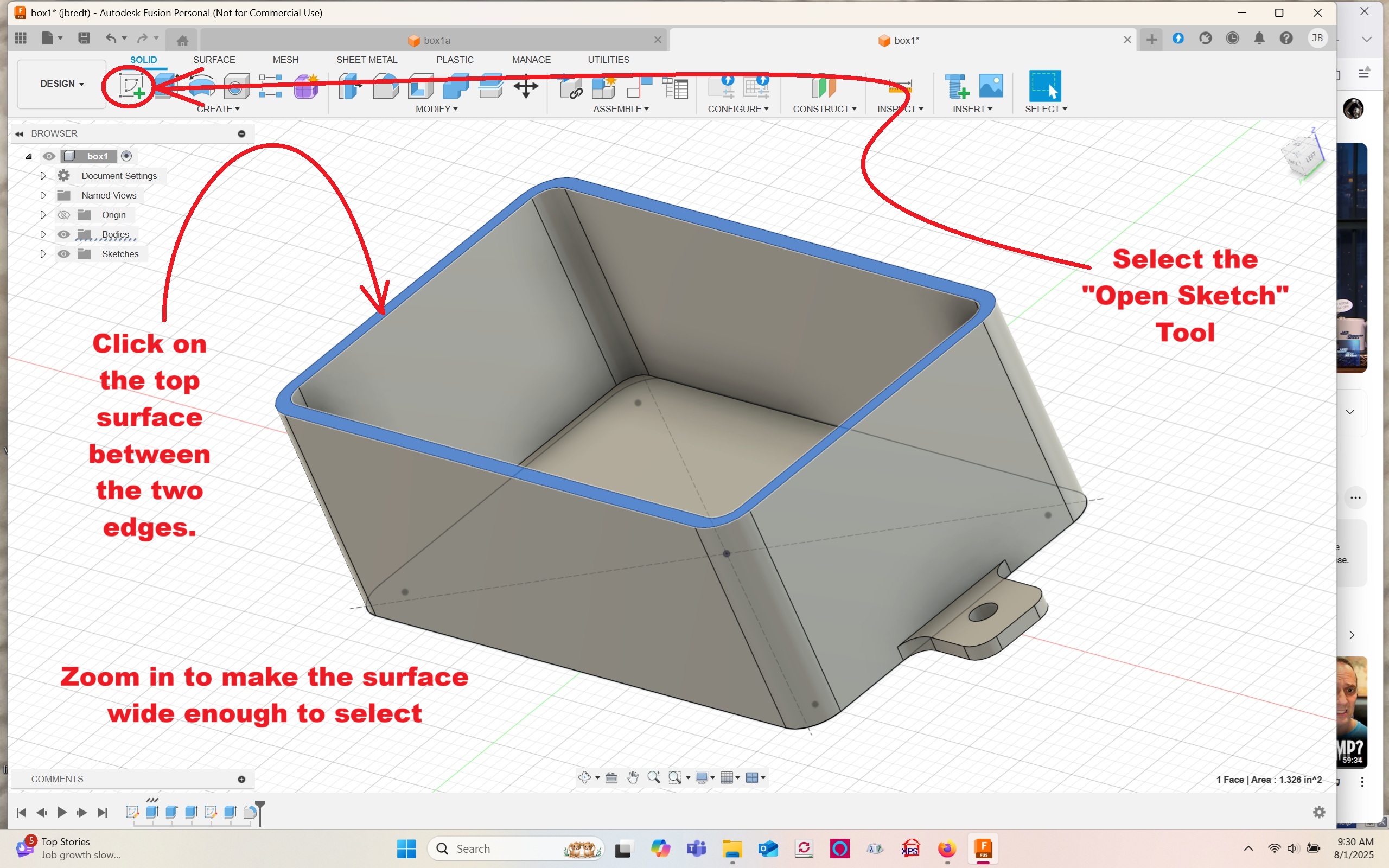

Lugs to hold a lid onto the top of the box are flush with the upper edge of the box. To draw on that plane, select the flat narrow upper surface of the edge of the box.

Select the (![]() ) "Corner Rectangle" tool. If you hover the cursor over the inside edge of the box, the cursor should "snap" onto the edge. Click and drag the cursor from one edge around the corner to the adjacent edge. Make sure the endpoints are both attached to the edges, as indicated by large black dots. Don't worry about the actual dimensions at this point.

) "Corner Rectangle" tool. If you hover the cursor over the inside edge of the box, the cursor should "snap" onto the edge. Click and drag the cursor from one edge around the corner to the adjacent edge. Make sure the endpoints are both attached to the edges, as indicated by large black dots. Don't worry about the actual dimensions at this point.

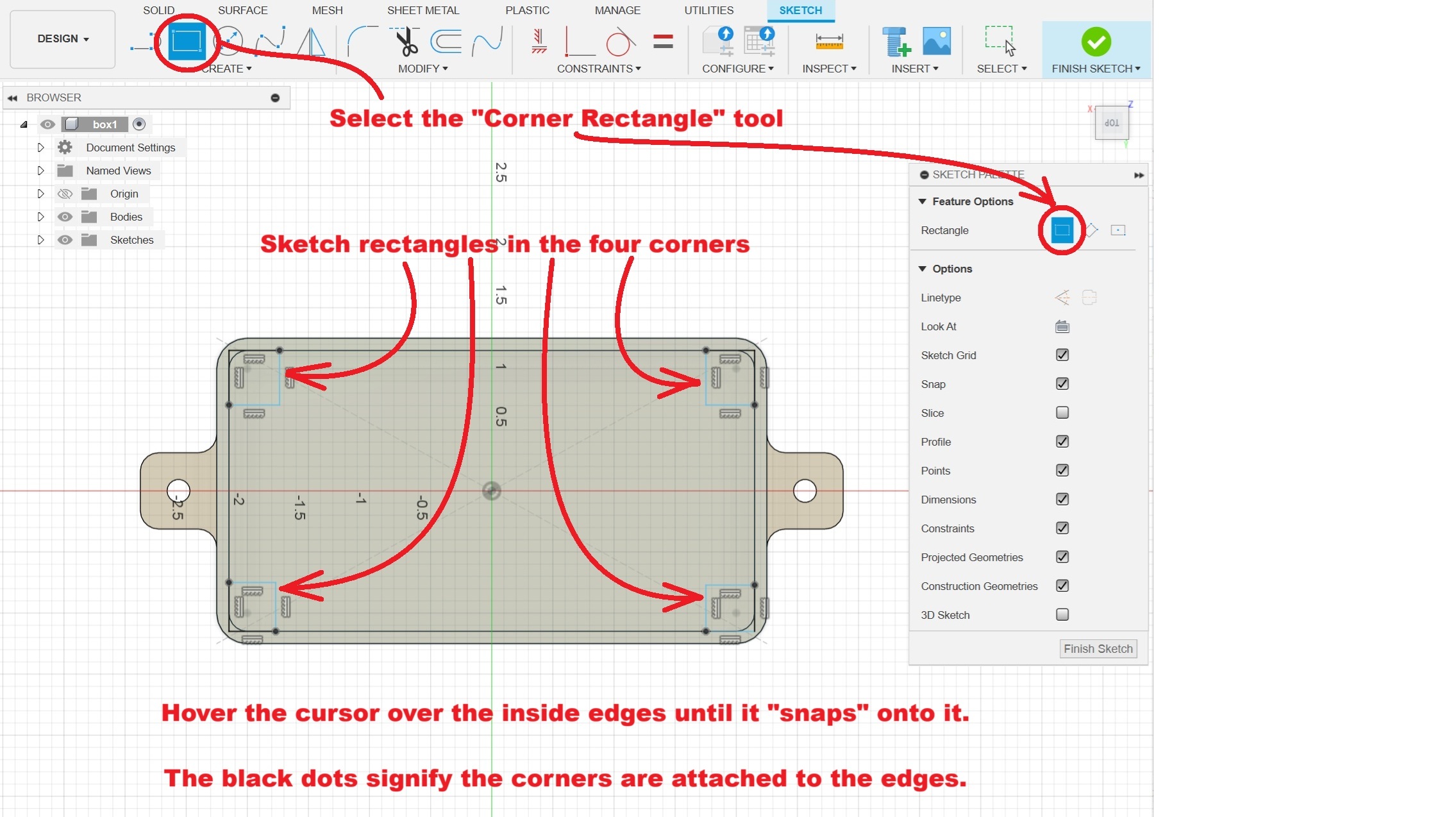

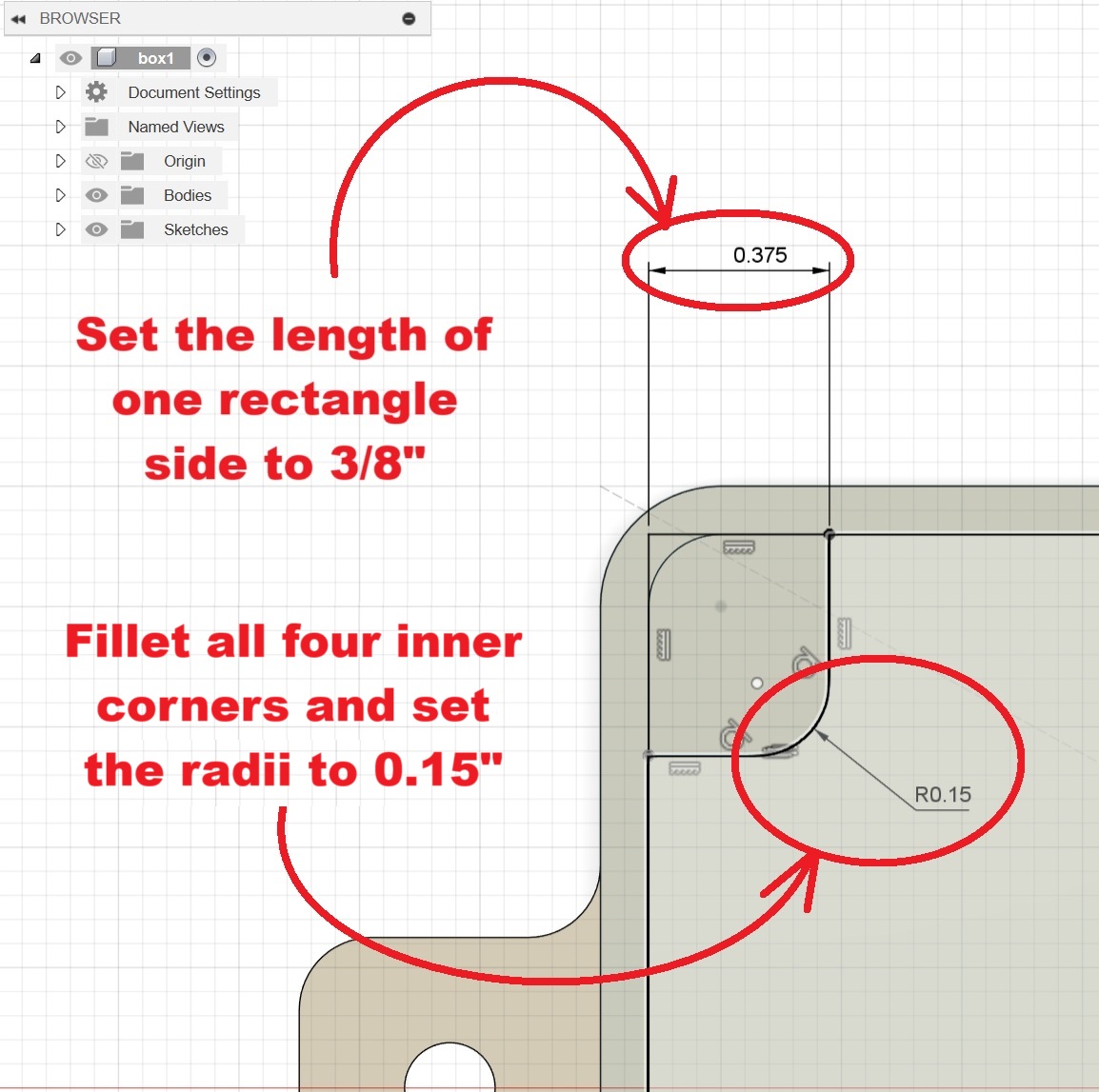

Select the (![]() ) "Sketch Dimension" tool from the "Create" menu. Set ONE dimension of one of the rectangles to 3/8" (0.375"). Select the (

) "Sketch Dimension" tool from the "Create" menu. Set ONE dimension of one of the rectangles to 3/8" (0.375"). Select the (![]() ) "Equal" tool and set the lengths of the other seven external rectangle edges to the same value. You will need to pick line segments in pairs, rather than selecting all of the segments at once. The edges to set are the ones that are collinear with the four edges of the box inner wall. You may want to review the section in the previous tutorial where this is done.

) "Equal" tool and set the lengths of the other seven external rectangle edges to the same value. You will need to pick line segments in pairs, rather than selecting all of the segments at once. The edges to set are the ones that are collinear with the four edges of the box inner wall. You may want to review the section in the previous tutorial where this is done.

Select the (![]() ) "Fillet" tool from the "Modify" group and fillet all four inside corners to a radius of 0.15". If you are unclear how to sketch these fillets, please refer to the earlier tutorial.

) "Fillet" tool from the "Modify" group and fillet all four inside corners to a radius of 0.15". If you are unclear how to sketch these fillets, please refer to the earlier tutorial.

Check the Constraints

This is a good opportunity to check the design to make sure all of the constraints are set correctly.

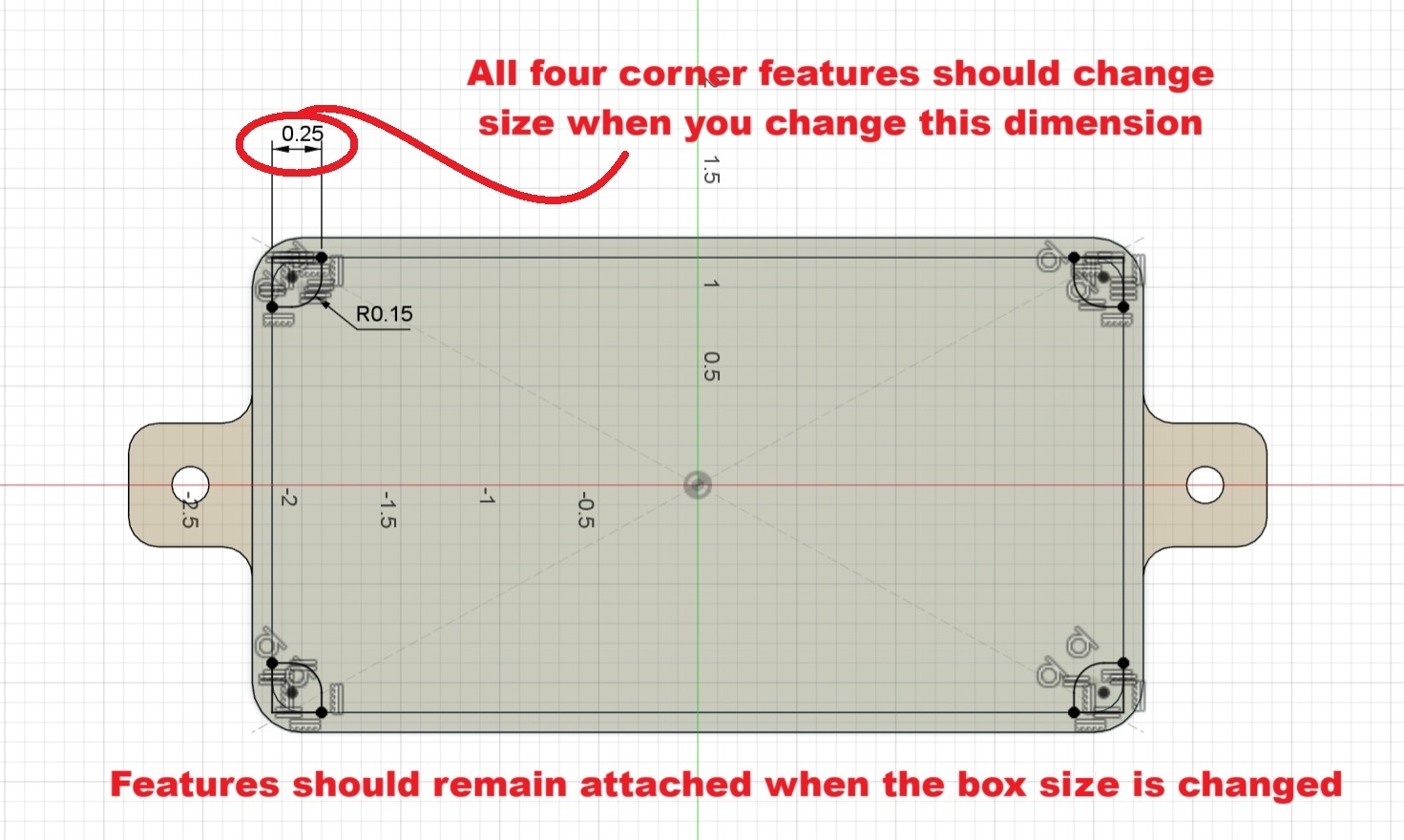

First, change the width dimension from 0.375 to 0.25. This is a more reasonable size for the design. All of the square features should change size at the same time and remain attached to the box corners.

Hit the "Finish Sketch" button to close the sketch.

Now reopen the first sketch in the set from the history list. The original 2.5" x 4.5" rounded-corner rectangle should appear with dimension bars. Double-click on each of these bars in turn and change the length and the width of the rectangle by an inch or so. Close the sketch and look at the result.

In the sketch you made most recently, the square features at the corners should still be attached to the corners of the box, even though the box has changed in size.

IF any of these features fails to move in the expected way, you will need to select some constraints to establish the correct relationships.

Restore the first sketch to its original dimensions because this size will be required soon.

Extrude the Lugs

The next step, in the normal sequence, is to take features in the most recent sketch and extrude them into the third dimension.

Make sure the most recent sketch is visible, as indicated by the (![]() ) eyeball in the margin of the list of sketches.

) eyeball in the margin of the list of sketches.

Select the (![]() ) "Extrude" tool from the "Create" group in the toolbar.

) "Extrude" tool from the "Create" group in the toolbar.