Oxy-Acetylene Torches

Link to: Metal Shop main page

Link to: Metal Shop tool list

| Extra precaution required for welders. Training / Tool Testing is essential. See Welding Safety doc. | |

|---|---|

| Eye protection required! | ||

|---|---|---|

| Oxy-Acetylene Torches | |

|---|---|

| General Info | |

| Make | Various |

| Model | n/a |

| Serial | Unknown |

| Specs | n/a |

| Manual | Victor manual |

| Asylum Info | |

| Location | Metal Shop |

| Rubric | n/a |

| Training | Tool classes |

| Testing | Tool testing, or come to the shop on Tool Testing Night |

| Restrictions | red |

Description

An oxy-acetylene torch is a device that mixes two gases inside the body of the hand-held torch and allows them to ignite when passing through a nozzle. The combustion flame when oxygen is combined with acetylene (C2H2) exceeds 3000°C (5500°F). This is more than sufficient for welding steel.

OA torches can be used for welding, cutting, brazing, and simple heating of metal pieces, most usually mild steel. A variety of nozzles are available for different tasks.

The fuel and oxygen are supplied from high-pressure cylinders that travel on a cart with a torch. These cylinders can be very dangerous if they are mishandled Do not use unless you have been properly trained and tool-tested.

Link to: Welding textbook

Use for:

- Heating or cutting metal, especially carbon steel.

- Brazing

- Welding (Arc may be preferable)

Do Not Use for

- Anything that might explode when heated.

- Anything that produces excessively noxious gases when heated or burned including:

- Galvanized

- Plated

- Painted

- Oiled

- Powder-coated

Hazards

| |

|---|---|

- Eye damage from looking at the flame for extended periods. Shade 5 eye protection required.

- Poisoning from gases produced when heating or vaporizing certain metals. Respirator required when appropriate.

- Injury or death from explosion due to tool misuse.

- Burns from flame, sparks, or hot workpieces.

- Two highly dangerous situations to watch for. Immediately shut down the torch if either occurs:

1. Pop sound. This is flashback.

2. Purple flame. Burning acetone from tank.

Brief Safety Notes

To avoid serious injury or death, be fully aware of how the tanks, regulators, and torches work in conjunction. Follow safe operating proceedures. For more safety information, see the document:Oxy-Acetylene Safety.

Beware of Flashback: An explosive situation in which Oxygen flows into the Acetylene hose. A pop sound indicates flashback. The equipment has flashback arrestors to keep the flame from backing into the tank. Still, beware.

Never use all the Acetylene in the tank. Tank Acetylene (Short Tank, Red Hose) is mixed with acetone to stabilize it under pressure. If you drain all the Acetylene, acetone will enter the torch to create and explosive situation. Note that Acetone burns purple.

Oxygen under pressure will ignite sawdust and grease. Tank Oxygen (Tall Tank, Green Hose) is under very high pressure. Oil on clothing or hands can combust under pure oxygen.

Avoid standing in front of the regulator especially when opening the cylinder valve. The weakest part of the regulator is the “bonnet,” which tends to be the first to go if the regulator explodes. The adjustment screw will shoot out with the speed of a bullet.

Keep the work area free of flammable or explosive materials especially paper, oil or grease, and flammable solvents such as acetone.

Always store tanks upright never use a tank that has been stored on its side – acetone is heavier than Acetylene and will be released during use and will enter the hose. Acetone burns purple.

If cutting, cut only one sheet at a time. Steel only. No stainless, no high carbon. Consider using a plasma cutter.

If you experience a sustained backfire (a shrill hissing sound when the flame is burning inside the nozzle) immediately turn off the Oxygen valve on the torch handle. Then, turn off the Acetylene valve. Allow the torch and nozzle time to cool before attempting to reuse. If backfire recurs, take the apparatus to a qualified repair technician for repair before using the equipment again.

Basic Operating Instructions

Starting Up

1. Before operation, perform a safety check on the equipment. Was it properly shut down? Were the gas cylinders stored properly?

- Are both cylinders chained up for safety?

- Are both cylinder valves closed?

- Are both regulators screws loose?

- Do all four regulator gauges read zero?

- Are all torch valves closed?

- If the answer is “NO” to any of the above complete the full shut-down procedure below. Be sure to purge the lines. Don’t take shortcuts or skip steps.

2. If needed, connect the torch head appropriate to your operation: Cutting head, welding tip, or heating tip. The shop provides several tip sizes.

3. Set the Acetylene working pressure. (Short Tank, Red Line)

- Open the Acetylene cylinder valve just enough to allow gas to flow. In case of emergency, closing this valve should take an instant.

- Open the Acetylene torch valve about 1/2 a turn.

- Turn the Acetylene regulator screw CLOCKWISE and read the Acetylene regulator gauge to set the pressure. (5 psi is a good beginning pressure.)

- Close the Acetylene torch valve.

NEVER open an Acetylene cylinder valve more than 1.5 turns.

| **Never set the Acetylene pressure higher than 15 psi.** It can explode! | |

|---|---|

4. Set the Oxygen working pressure. (Tall Tank, Green Line)

- Stand aside from the oxygen regulator. Using two hands, SLOWLY open the Oxygen cylinder valve until the gauge needle stops moving. This reduces the shock of high cylinder pressure on the regulator and reduces the probability of an explosion.

- Turn the oxygen cylinder valve all the way open. The Oxygen cylinder has a seat on the top and bottom that prevents leakage when fully open or fully shut.

- Open the Oxygen torch valve about 1/2 a turn.

- Turn the Oxygen regulator screw CLOCKWISE and use the Oxygen regulator gauge to set the pressure. (5 psi is a good beginning pressure.)

- Close the Oxygen torch valve.

| |

|---|---|

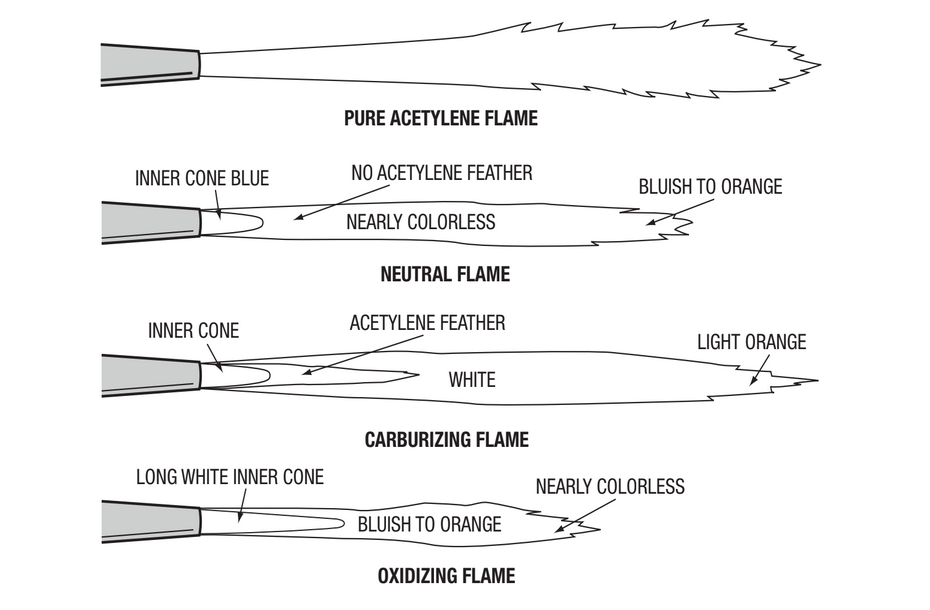

| Oxy-Acetylene Flames (from Victor manual) |

5. Light the torch (Oxygen won’t ignite with a striker, so Acetylene must be lit first.)

- Open the Acetylene torch valve about 1/2 a turn.

- Use a striker to light the Acetylene flame. A gap between the flame and the torch tip indicates too much Acetylene. Use the torch valve to reduce the flow of Acetylene. Adjust as needed.

- SLOWLY open the Oxygen torch valve.

- Adjust the flame using both torch valves as needed to produce a carburizing, neutral, or oxidizing flame.

Shutting Down

| To prevent an explosion, NEVER purge both gases at the same time. | |

|---|---|

1. Extinguish the torch.

- Close the Oxygen torch valve first.

According to the Victor manual, “Oxygen first” provides users the chance to perform leak checks on both valves every time the torch is shut down. A snap or a pop indicates a leaking oxygen valve, while a small flame at the end of the tip indicates an acetylene gas leak.

- Close the Acetylene torch valve second.

2. Purge the Oxygen lines

- Close the Oxygen cylinder valve. (This cuts the gas off at the source.)

- Open Oxygen torch valve and wait / listen for Oxygen to fully purge from line.

- Check that both Oxygen gauges read zero.

- When the purge is complete and the gauges read zero, turn the Oxygen regulator screw COUNTERCLOCKWISE until slightly loose. Do not remove the screw. If the regulator screw is loosened out of sequence, gas can get trapped in the line between the two regulators.

- Close the Oxygen torch valve. Do not over-tighten.

3. Purge the Acetylene lines.

- Repeat the above steps using the corresponding components.

4. Clean the work area and put equipment away.

- Neatly coil the hoses. Return the equipment rig to its storage location.

Videos

Westcott video on good torch practice

Mythbusters episode on gas cylinder rocketry

Supplemental Safety Information

1. Blow out the cylinder valves before attaching regulators. This ensures there is no dirt, rust, lubricant, etc. on the valves. Inspect the valve, then move to the opposite side and open the valve briefly to blow out contaminants. (Point the valve away from yourself when blowing it out.) No grease or oil on the threads of the regulator, or anywhere near Oxygen. These substances can spontaneously combust with Oxygen.

2. Release the adjusting screws on the regulators before opening the cylinder valves. This eliminates pressure on the regulator diaphragm, shutting off the regulator so that the high pressure of the tank does not enter the inner workings of the regulator or beyond. This reduces the probability of an explosion.

3. Do not stand in front of regulator when opening the cylinder valve. The weakest part is the “bonnet,” which tends to go first if the regulator explodes. An explosion can blow the adjusting screw out like a bullet.

4. Open the cylinder valve slowly. Shock of high pressure may damage the regulator, and can increase the size of an explosion, especially with Oxygen. Crack the valve, watch the regulator needle jump, and then check that it has stopped moving. After the needle stops moving, continue to open the cylinder valve.

-Oxygen- open fully. It has a seat on the top and bottom that prevents leakage when fully open or fully shut.

-Acetylene- only open 1/4 to 1/2 a turn. This makes it easy to shut off in an emergency (i.e. flashback)

5. Do not set the Acetylene pressure above 15 psi. It is unstable and likely to explode above 15 psi. It’s rare to need as much as 10 psi, even for cutting steel.

6. Open the Oxygen and Acetylene gas lines individually before lighting the torch. This cleans out any potentially dangerous gas mixtures that may be in the hose or regulators. It also allows you to set your working pressure with the gas flowing prior to lighting the torch.

7. Always light the Acetylene first before opening the Oxygen valve on the torch. Worse case scenario: Oxygen flows back into the Acetylene line and causes the regulator to explode.

8. Never use oil or grease around Oxyacetylene equipment. Oil around pure oxygen can spontaneously combust with no spark at all. Beware of grease on hands, clothing, and rags that come in to contact with the equipment.

9. Never use oxygen as a substitute for compressed air.

10 Keep the work area clear of anything that will burn. Sparks can travel.

11. Always wear eye protection.

12. Cylinders should always be upright, securely fastened to prevent tipping, and capped when not in use.

13. Make sure cap is in place when moving a cylinder, and never use the cap to pick up the cylinder. Use a cylinder hand truck.

14. Secure a cylinder before removing its cap.

15. Never use a regulator designed for one type of gas on a cylinder for a different type of gas

16. Never use gas from a cylinder without using a regulator.

17. Always close the valve on empty cylinders to prevent dirt and moisture entering the tank.

18. Never subject tanks to temperatures above 125 degrees F