Category:Plasma Shop: Difference between revisions

| (6 intermediate revisions by the same user not shown) | |||

| Line 42: | Line 42: | ||

Do not place tools one the side rails of the cutting tank. These are part of the mechanism and obstructions can damage the machine. | Do not place tools one the side rails of the cutting tank. These are part of the mechanism and obstructions can damage the machine. | ||

==Maintenance notes== | |||

[[media: Topping the Water Tank.pdf | Topping up the water in the tank]] (every week) | |||

[[media: Cleaning and Lubricating the Mechanism.pdf | Clean and Lube]] (every month or two) | |||

[[media: Calibrating the Vertical Stage.pdf | Measuring the backlash]] (every month or two) | |||

[[media: Planing the CNC work surface.pdf | Planing the work surface]] (twice a year) | |||

== Documentation == | == Documentation == | ||

'''The following documents are available:''' | '''The following documents are available:''' | ||

[[:Category:Bracketage |Solidworks tutorials]] showing the data path for designing and fabricating sheet metal parts using the plasmatron. | |||

Link to [https://drive.google.com/file/d/14TK3ZsdimfMVv3-gyWi3wz_3wzfEAER_/view?usp=drive_link Torchmate user manual] | Link to [https://drive.google.com/file/d/14TK3ZsdimfMVv3-gyWi3wz_3wzfEAER_/view?usp=drive_link Torchmate user manual] | ||

| Line 53: | Line 65: | ||

Data for machine settings can be found in the Hypertherm manual [https://drive.google.com/file/d/14TK3ZsdimfMVv3-gyWi3wz_3wzfEAER_/view?usp=drive_link Torchmate PowerMax85] or on the [[Plasma CNC Machine Settings]] page. | Data for machine settings can be found in the Hypertherm manual [https://drive.google.com/file/d/14TK3ZsdimfMVv3-gyWi3wz_3wzfEAER_/view?usp=drive_link Torchmate PowerMax85] or on the [[Plasma CNC Machine Settings]] page. | ||

Training is available by taking a class and review of the [https://drive.google.com/file/d/ | Training is available by taking a class and review of the [https://drive.google.com/file/d/1PRsRqTug9Yh1PXNv7A6d63P6PcKDlWNf/view?usp=drive_link User training document] | ||

A table of [[Powermax 85 Error Codes]] displayed on the front display of the Hypertherm power supply. | A table of [[Powermax 85 Error Codes]] displayed on the front display of the Hypertherm power supply. | ||

Instructions for starting and stopping the [[Antwerp Air Compressor]] | Instructions for starting and stopping the [[Antwerp Air Compressor]] | ||

Latest revision as of 14:19, 16 June 2024

| CNC Plasma Cutter | |

|---|---|

| CNC Plasma Cutter | |

| Building | Antwerp |

| Lead | Sam Feine |

| User email list | plasmashop-users@artisansasylum.com |

| Tool Testers |

Jim Bredt |

| Hours | Same as membership hours |

There is only one tool in this shop.

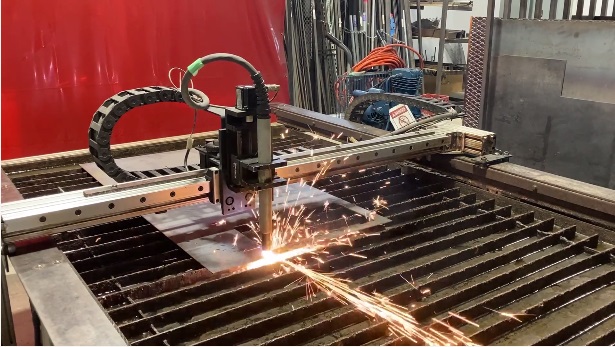

Torchmate CNC Plasma Cutter

Description:

The tool consists of a CNC gantry with a 48"x96" table that carries a Hypertherm PowerMax85 plasma torch. Cuts are made vertically over a water tank. Four levels of torch power are available so that mild steel sheets ranging from 0.018" (26-Ga) to 1.25" thick may be cut. Maximum cut speed is 350 inches per minute.

This is a RED tool! Users must be trained and tool-tested before they are permitted to operate it.

Materials qualified for general use are: Mild Steel, Stainless Steel, and Aluminum. Other materials that have been successfully tested are: Titanium and Brass.

Driver software is called Torchmate 4 located on the attached computer and several installations around the Asylum. Input data is in the form of a 2-D sketch, either as G-Code (*.txt or *.fgc) or DXF (*.dxf). DXF files may be prepared on any convenient CAD syatem, including a resident program "Torchmate CAD" located on the drive computer. Alternatively, G-Code may be prepared separately as a text file and opened by "Torchmate 4" application.

Location:

Artisans Asylum Antwerp Building, 55 Antwerp Street, Allston. Adjacent to the Metals Shop in the northeast corner of the building.

Safety Rules

PROTECT YOUR EYES! Always wear eye protection and wear shaded goggles when the torch is cutting.

The power switch for the ventilator is located on the wall to the left of the drive computer, adjacent to the sheet metal rack.

The emergency cutoff button (E-STOP) is located on the corner of the table nearest to the shop entry.

A sink is located on the wall opposite the drive computer.

A fire extinguisher is located adjacent to the sink.

In the unlikely event of a flammable metal fire, DO NOT ATTEMPT TO EXTINGUISH. Call 9-1-1 and evacuate the area.

Do not place tools one the side rails of the cutting tank. These are part of the mechanism and obstructions can damage the machine.

Maintenance notes

Topping up the water in the tank (every week)

Clean and Lube (every month or two)

Measuring the backlash (every month or two)

Planing the work surface (twice a year)

Documentation

The following documents are available:

Solidworks tutorials showing the data path for designing and fabricating sheet metal parts using the plasmatron.

Link to Torchmate user manual

Exploded views of the nozzle packs: Fine Cut ; Coarse Cut

Data for machine settings can be found in the Hypertherm manual Torchmate PowerMax85 or on the Plasma CNC Machine Settings page.

Training is available by taking a class and review of the User training document

A table of Powermax 85 Error Codes displayed on the front display of the Hypertherm power supply.

Instructions for starting and stopping the Antwerp Air Compressor

This category currently contains no pages or media.