Category:Lathes -- Metal: Difference between revisions

No edit summary |

No edit summary |

||

| Line 34: | Line 34: | ||

A lathe is a machine tool that turns workpiece on a rotating spindle and allows the operator to cut it with a sharp tool. A metal or plastic workpiece is held in a chuck and a sharp cutting tool is manipulated on a moving tool holder by manual motion; or by a mechanized drive geared to the spindle; or by CNC. | A lathe is a machine tool that turns workpiece on a rotating spindle and allows the operator to cut it with a sharp tool. A metal or plastic workpiece is held in a chuck and a sharp cutting tool is manipulated on a moving tool holder by manual motion; or by a mechanized drive geared to the spindle; or by CNC. | ||

Cutting tools are most often simple sharpened square bars of high-speed steel that are clamped to a moving tool post. Drills and various specialized cutting tools are also avaialble. | |||

Link to: [https://drive.google.com/file/d/1seuiCHsli8SDRUk0GXnYwTaPPqchwlbK/view?usp=drive_link Online lathe textbook] | Link to: [https://drive.google.com/file/d/1seuiCHsli8SDRUk0GXnYwTaPPqchwlbK/view?usp=drive_link Online lathe textbook] | ||

| Line 56: | Line 58: | ||

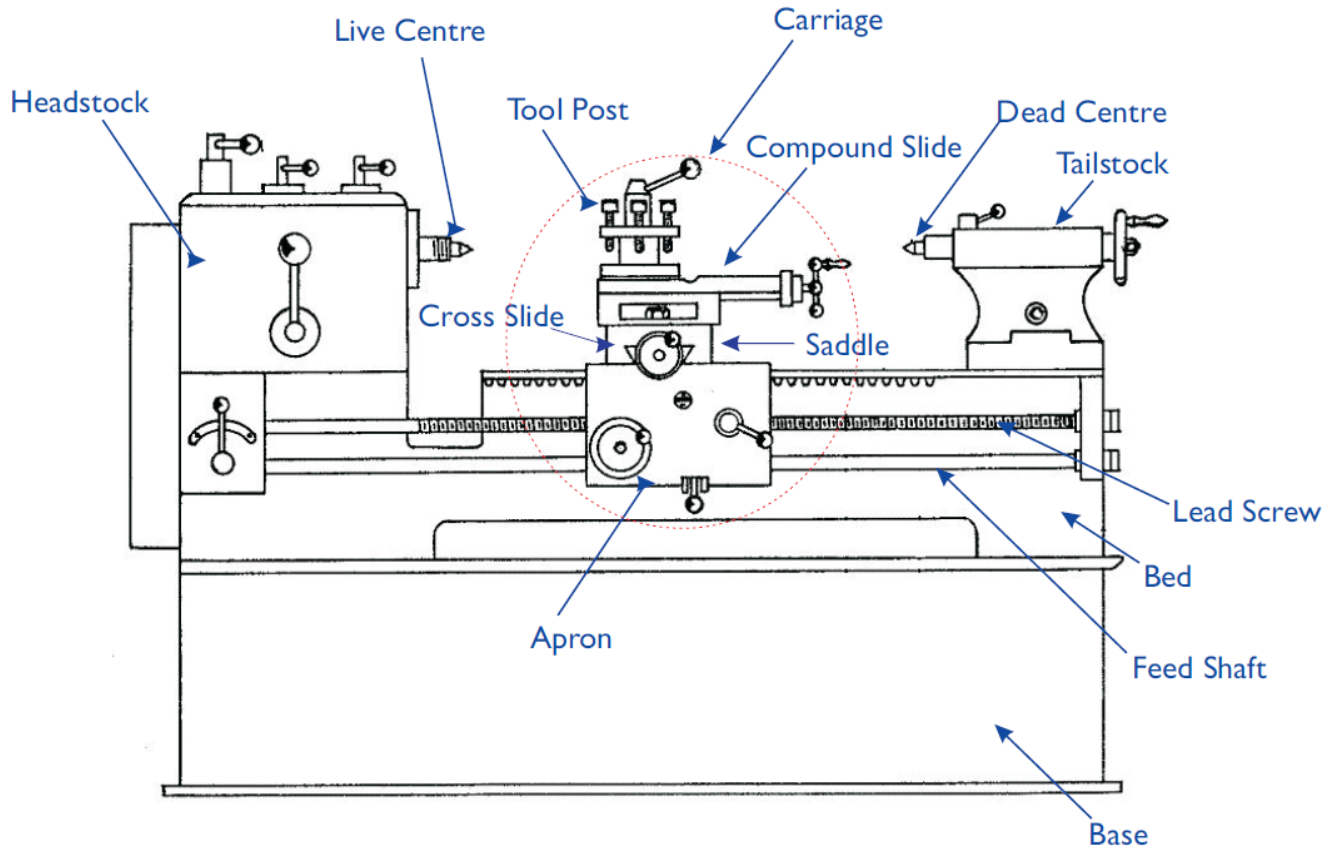

==Parts of a Lathe== | ==Parts of a Lathe== | ||

'''Headstock''' | |||

Traditionally located on the left side of the machine, the spindle is most usually belt-driven and speed controls are located on it. | |||

The spindle is hollow to accommodate long workpieces. A variety of mounting fixtures are available: Collets, face plates, and chucks. | |||

{| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | {| class="infobox" cellspacing="5" style="width: 22em; text-align: left; font-size: 100%; line-height: 1.5em;" | ||

! colspan="2" class="infobox-image" | [[File:parts_of_a_lathe2_labeled.png|650px|front panel unlabeled ]] | ! colspan="2" class="infobox-image" | | ||

[[File:parts_of_a_lathe2_labeled.png|650px|front panel unlabeled ]] | |||

|- | |- | ||

| colspan="2" | Major parts on a lathe | | colspan="2" | Major parts on a lathe | ||

|- | |- | ||

|} | |} | ||

'''Bed''' | |||

The smooth, precisely milled '''ways''' on the bed ensure that the motion of the carriage and tailstock are perfectly parallel to the axis of rotation of the spindle. The bed also carries a precision '''lead screw''' that can be used to drive the carriage for machining and thread cutting. | |||

'''Carriage''' | |||

An '''apron''' rides on the ways. It contains drive gears and a split nut that can be opened and closed over the lead screw to automate its motion. The apron can be also moved manually with a crank. | |||

The '''cross-slide''' is carried on the apron and moves perpendicular to the spindle axis. It has a wheel for fine adjustments similar to the cross-feed on a milling machine. | |||

The '''compound rest''' rides on the cross-slide. It can swivel and slide back and forth on top of the carriage and it holds the cutting tool. | |||

A '''tool post''' mounts to the compound rest and clamps the cutting tool in place. | |||

'''Tailstock''' | |||

The tailstock supports the workpiece at the right end of the bed. A long workpiece would be supported by a "center," a pointed tool that keeps the workpiece fixed on its axis of rotation. The tailstock also permits drill bits to be chucked and fed into the spinning workpiece. | |||

Revision as of 21:59, 12 March 2024

| Eye protection required! | ||

|---|---|---|

| Metal-Cutting Lathes | |

|---|---|

| General Info | |

| Make | various |

| Model | |

| Serial | |

| Specs | |

| Manual | |

| Asylum Info | |

| Location | Machine Shop |

| Rubric | |

| Training | |

| Testing | |

| Restrictions | red |

Description

A lathe is a machine tool that turns workpiece on a rotating spindle and allows the operator to cut it with a sharp tool. A metal or plastic workpiece is held in a chuck and a sharp cutting tool is manipulated on a moving tool holder by manual motion; or by a mechanized drive geared to the spindle; or by CNC.

Cutting tools are most often simple sharpened square bars of high-speed steel that are clamped to a moving tool post. Drills and various specialized cutting tools are also avaialble.

Link to: Online lathe textbook

| Use For | Do Not Use For |

|---|---|

|

|

Parts of a Lathe

Headstock

Traditionally located on the left side of the machine, the spindle is most usually belt-driven and speed controls are located on it.

The spindle is hollow to accommodate long workpieces. A variety of mounting fixtures are available: Collets, face plates, and chucks.

| Major parts on a lathe |

Bed

The smooth, precisely milled ways on the bed ensure that the motion of the carriage and tailstock are perfectly parallel to the axis of rotation of the spindle. The bed also carries a precision lead screw that can be used to drive the carriage for machining and thread cutting.

Carriage

An apron rides on the ways. It contains drive gears and a split nut that can be opened and closed over the lead screw to automate its motion. The apron can be also moved manually with a crank.

The cross-slide is carried on the apron and moves perpendicular to the spindle axis. It has a wheel for fine adjustments similar to the cross-feed on a milling machine.

The compound rest rides on the cross-slide. It can swivel and slide back and forth on top of the carriage and it holds the cutting tool.

A tool post mounts to the compound rest and clamps the cutting tool in place.

Tailstock

The tailstock supports the workpiece at the right end of the bed. A long workpiece would be supported by a "center," a pointed tool that keeps the workpiece fixed on its axis of rotation. The tailstock also permits drill bits to be chucked and fed into the spinning workpiece.

Pages in category "Lathes -- Metal"

The following 5 pages are in this category, out of 5 total.