Category:Milling Machines

| Vertical Milling Machines | |

|---|---|

| General Info | |

| Make | various |

| Model | |

| Serial | |

| Specs | |

| Manual | |

| Asylum Info | |

| Location | Machine Shop |

| Rubric | |

| Training | |

| Testing | |

| Restrictions | red |

Description

On a milling machine, parts are created by removing material from a solid block (or workpiece) using a variety of spinning cutting tools.

A 3-axis vertical milling machine has a variable-speed vertical spindle and a heavy table that translates underneath it. A metal workpiece is clamped to the table and a cutting tool is held in the spindle. Cutting is done by moving the workpiece against the spinning tool, or by lowering the spinning tool into the workpiece.

A CNC milling machine operates by computer control. Motors are attached to the movement mechanics allowing the computer to make precision-machined parts automatically.

| Use For | Do Not Use For |

|---|---|

|

|

Safety Notes

| Eye protection required! | ||

|---|---|---|

Personal

- Wear safety goggles. Eyeglasses are NOT safety goggles.

| |

|---|---|

- Beware of flying chips. They are HOT and SHARP.

- Do not wear loose clothing or jewelry when operating the machine. Long hair must be tied back or covered.

- Do not wear gloves. Gloves can be drawn into a cut by the spinning tool.

- Do not remove chips from the cutting area with bare hands. Use a chip brush or a shop-vac.

- Always keep a secure, stable stance. Avoid over-reaching. Clean up oil spills immediately and avoid slipping. Keep the work area clear of trip hazards.

Machine

- Work must be clamped securely in a vise and the vise clamped tightly to the table, or, work must be clamped securely to the table.

- Always stay at the machine while it is running.

- Do not operate the machine if any unusual or excessive heat, noise, smoke, or vibration occurs.

- Make sure the spindle has come to a complete stop before changing tools or unloading the workpiece. Keep hands clear of the spindle start switch when changing tools.

- NEVER USE COMPRESSED AIR to remove chips from the work area.

- Remove all wrenches, chuck keys, and loose parts before turning on the machine.

- Before running machine the spindle should be rotated by hand to make sure it is clear for cutting.

- Make sure the cutter is rotating in the proper direction before cutting material.

- Always use sharp cutters that are in good condition.

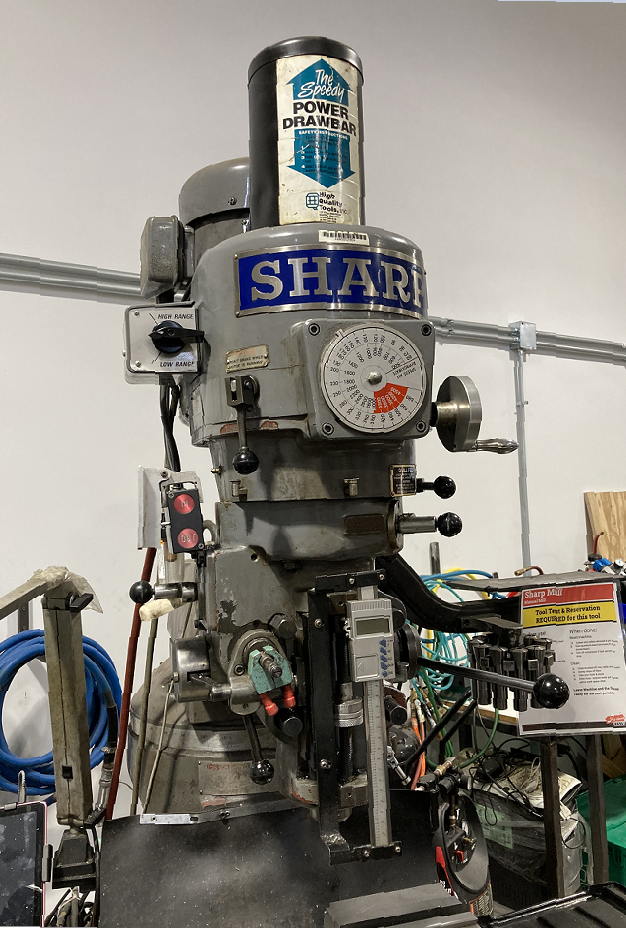

| Accu II Mill | Enco Mill | Sharp Mill "Click" | Sharp Mill "Clack" | Bridgeport Mill |

|---|---|---|---|---|

| CNC | Manual | Manual | Manual | Manual (Out of Service) |

|

|

|

|

|

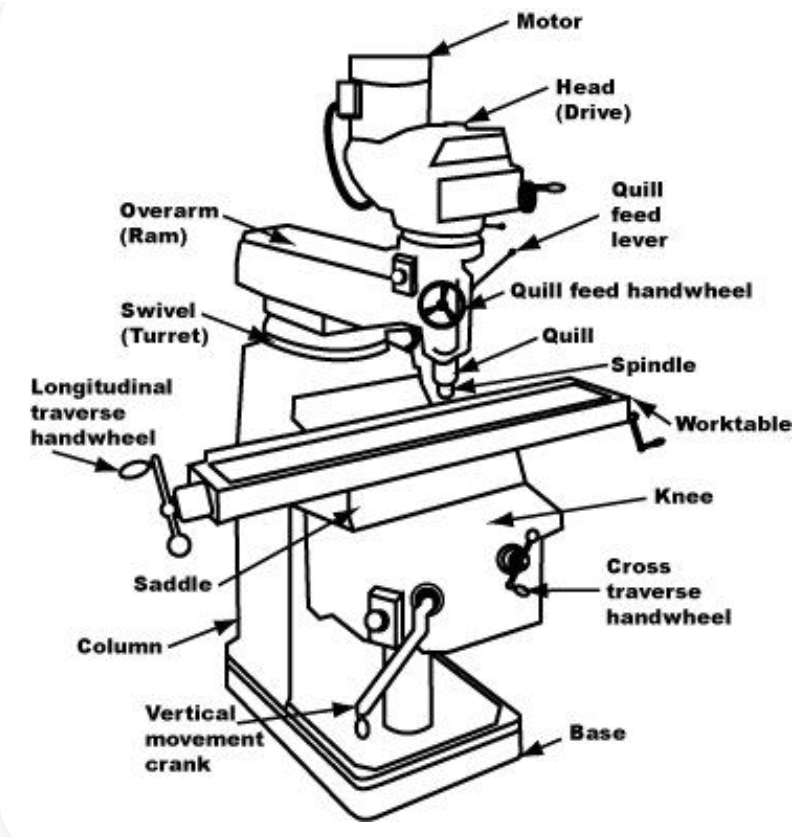

Parts of a Milling Machine

| |

|---|---|

| Parts of a Milling Machine |

Headstock:

The spindle is driven by the motor at the top. Frequently there is a crank-operated speed control located on the front.

An emergency stop (E-STOP) button is always located next the the motor power switch.

The spindle is raised and lowered through the Quill, actuated by a handle on the side of the headstock.

Tools are held in place with a drawbar that extends through the center of the spindle. The draw-bar can be tightened manually or with a pneumatic motor.

Table:

The moving table is carried on the machine's saddle.

Side-to-side (Longitudinal) motion of the table is controlled by ball crank handles on either end of the table. The scales are incremented by 0.001 inches.

Knee:

In-and-out (Cross) motion of the table is controlled by a crank on the front of the knee, also incremented by 0.001 inches.

The table is raised and lowered vertically by a crank on the side of the knee.

Base and Turret

These provide stability and allow some adjustment of the headstock.

Machine Motion

The X-Y motion of the table and the vertical motions of the knee and the spidle are all actuated by gears and screws, which turn rotary motion into linear motion.

Manual Actuation

| |

|---|---|

| The scale is graduated in "mils" or 1/1000ths of an inch. |

| |

|---|---|

| Hand-cranking the table on a mill |

On a manual machine, the motion is created by turning the mechanical input with a crank or a handle. On the table cranks, an "ACME" screw creates a movement of 0.2 inches per rotation.

With this motion, the user must account for the backlash of the screw and the nut riding on it. On a typical mill, this backlash can be approximately 1/20 rotation, or about 0.01 inches in distance.

Mechanization

| |

|---|---|

| An add-on motor drive with a clutch on the Enco mill. |

On some machines, an electric motor is attached to one or more axes of motion. This permits the user to set a uniform speed for milling off a flat surface with an even linear movement.

A cluch handle engages the motor to the hand-crank for motion in either direction.

On many machines, the spindle has a mechanized vertical movement geared into the spindle rotation, for drilling.

CNC

Pages in category "Milling Machines"

The following 6 pages are in this category, out of 6 total.