Category:Machine Shop: Difference between revisions

No edit summary |

(→Tools) |

||

| Line 37: | Line 37: | ||

| [https://www.artisansasylum.com/tool-testing Sign up for tool test] | | [https://www.artisansasylum.com/tool-testing Sign up for tool test] | ||

{{ ToolTableItemRed | link=[[Do-All Vertical Bandsaw]] }} | {{ ToolTableItemRed | link=[[Do-All Vertical Bandsaw]] }} | ||

| [https://www.artisansasylum.com/tool-testing Sign up for tool test] | |||

{{ ToolTableItemRed | link=[[15-inch Metal-Cutting Vertical Bandsaw]] }} | |||

| [https://www.artisansasylum.com/tool-testing Sign up for tool test] | | [https://www.artisansasylum.com/tool-testing Sign up for tool test] | ||

{{ ToolTableItemGreen | link=[[General Hydraulic Shop Press]] }} | {{ ToolTableItemGreen | link=[[General Hydraulic Shop Press]] }} | ||

Revision as of 20:44, 23 October 2024

| Machine Shop | |

|---|---|

| Machine Shop | |

| Building | Antwerp |

| Lead | Doug Ruuska |

| User email list | machineshop-users@artisansasylum.com |

| Tool Testers | |

| Hours | Same as membership hours |

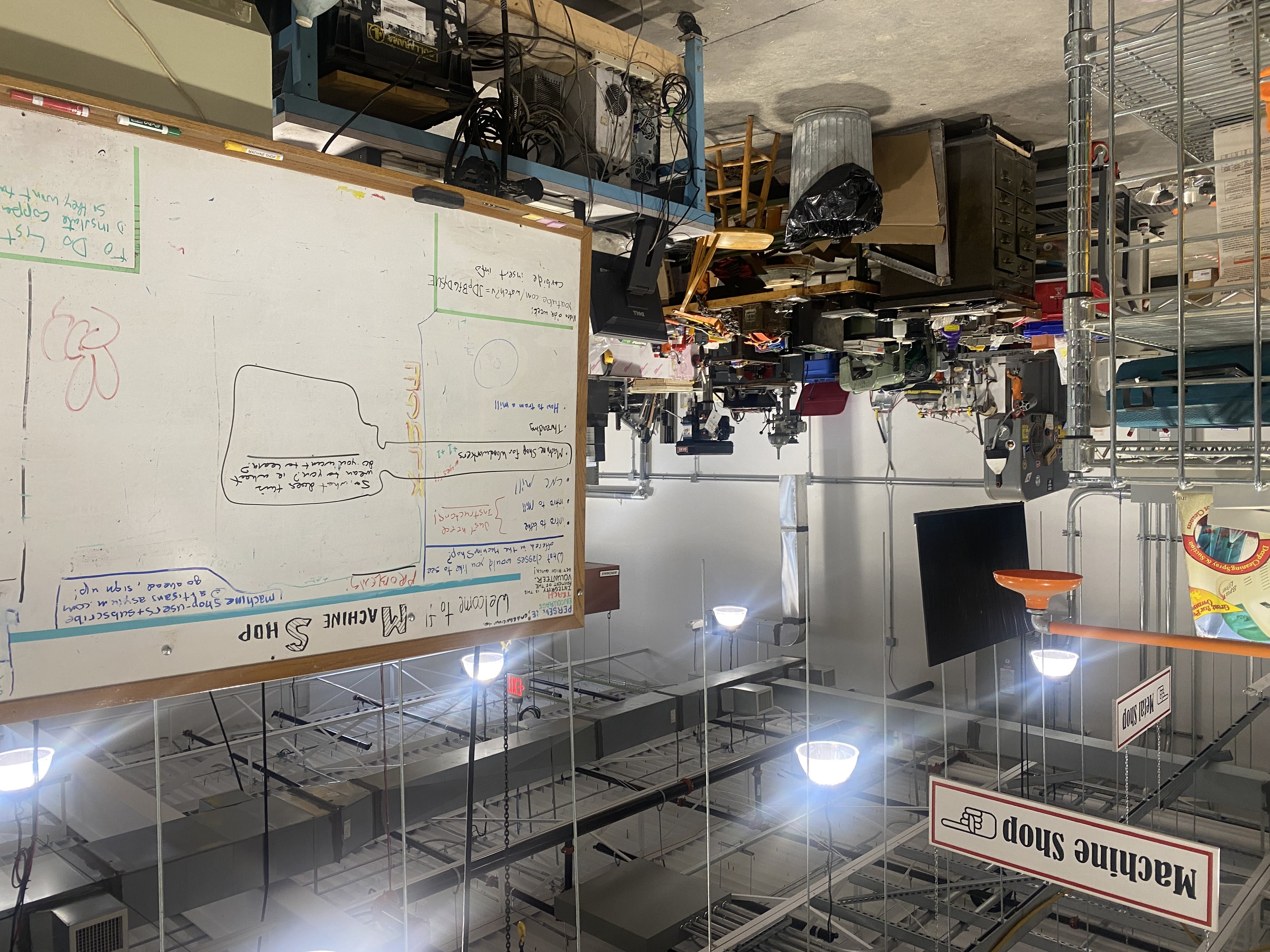

Machine Shop

- Shop Safety and Etiquette (not machine shop specific)

Shop Night Social

Shop Night happens the 2nd Wednesday of every month and is a great opportunity to get involved with the Machine Shop. It's open to everyone and anyone who's willing and available to clean, fabricate infrastructure, sort consumables, and organize the shop. Shop night usually goes from 6pm to 10pm and there's usually some free pizza! Make sure to sign up for the mailing list to be the first to know.

Tool Testers

- Art Torrey

Tools

| Tool | Class | Tool Tester(s) |

|---|---|---|

| Acer Dynamic 1340G Manual Lathe (link to user manual) | RED | Art Torrey |

| Bridgeport Series 1 Standard Knee Mill | RED | Sign up for tool test |

| Dake SB-32V Drill Press | RED | Sign up for tool test |

| DaVinci CNC Mill | RED | Sign up for tool test |

| Do-All Vertical Bandsaw | RED | Sign up for tool test |

| 15-inch Metal-Cutting Vertical Bandsaw | RED | Sign up for tool test |

| General Hydraulic Shop Press | GREEN | no testing needed |

| Johnson Horizontal Bandsaw | RED | Sign up for tool test |

| Logan Manual Lathe | RED | Art Torrey |

| M3X CNC Milling Machine | RED | Through the CNC class only |

| Millport SmartLathez 1740 CNC Lathe | RED | (Not yet in service) |

| Mitsui MSG 200MH Surface Grinder | RED | (not yet in service)] |

| Palmgren 15-inch Vertical Bandsaw | RED | Sign up for tool test |

| Sharp Manual Milling Machine (Two units) | RED | Sign up for tool test |

| South Bend Manual Lathe | RED | Art Torrey |

| Tormach 15L CNC Slant Lathe (Two units) | RED | (Not yet in service) |

| Walker-Turner Drill Press | RED | Sign up for tool test |

Tool recommendations from members

Get digital micrometers from Mitutoyo, the batteries last for years, I recommend: Calipers: https://www.amazon.com/gp/product/B01LPIWAYO?th=1 Micrometer: https://www.amazon.com/gp/product/B00MBHXWGY

Edge finders are a pain, it’s probably outside your budget, but if this is for your own shop invest in a Haimer 3D sensor, expensive but worth it, mine has certainly paid for it self in time saved and f-ups avoided. https://www.amazon.com/gp/product/B008VW7D1S

If this is for A2: Get dial indicators and vernier mics from aliexpress, they aren’t the greatest quality but they will work and last and the batteries and electronics can’t dies, shars and other lower quality suppliers just find the most popular ones, have the manufacture put their brand name on them, import them and mark them up.

For both you and A2:

Endmills and drill bits, lathe tooling, inserts, I buy all mine from aliexpress, they are 1/5th the cost of anywhere else and I can’t tell the difference. I like the short carbide drill bits they are split bit and sturdy so you don’t need a centering bit https://www.aliexpress.us/item/3256802372240173.html

While we’re on lathe tooling & inserts, most carbide inserts are designed for high speed turning with coolant for materials that are designed to be machined. A36 steel (common steel) is horrible and gummy. If you want to machine that or other things at low speeds the common belief is that you should use HHS and learn how to grind tooling yourself. Cool, but kinda of a pita, you can also get ground carbide inserts which are sharp enough to get good surfaces finishes even at lower speeds without. These have worked great for me: https://www.aliexpress.us/item/3256804145157346.html You get 6 cutting edges for $3-4 per insert.

Finally lighting: Can’t understate how importing having good lighting is: I found these : https://www.aliexpress.us/item/3256802052489129.html They are insanely bright, If I put them close enough to what I’m welding, I can see my work through a fixed shade lens. Magnet means they can stick to everything, make sure to get the US plug.

I’ll tell you what I tell my Intro students, it all depends. If you think that you will ever be taking/using your tools in a professional environment, Starrett, Brown and Sharp, Fowler, Mitoya are your choices. I have had several challenges by clients over the years who backed off when I showed them the measurements in front of them. But I also have a wooden “yard stick” that gets used sometimes!

One tool that I would recommend you spend a few extra bucks on is a Starrett combination square with a hardened head. It comes as a three piece kit with a center finder(handy for lathe work when marking the end of a round) and a protractor. Mine is over 40 years old and I use it for tramming the head on the Bridgeport. I did a demo last month and we double checked it with a dial indicator and off by .002 over 5 inches, pretty close for a quick setup! You can get the rule graduated in 1/10s or 1/100/s graduation (basically decimal inch) instead of fractions. If you contact Starrett directly (local Massachusetts company), I usually call, they will give you a product number and you can order it from MSC direct.

Digital calipers are really handy, but I don’t trust them to be better than +- .002” and have owned several including Starrett (only tool I wouldn’t buy from them) Fowler, and Brown and Sharp. With those two tools you can measure almost anything.

A 1 inch Micrometer is also indispensable. Also a 6 inch steel rule is really handy for lathe work, setting tool center heights.

Subcategories

This category has the following 3 subcategories, out of 3 total.

Pages in category "Machine Shop"

The following 25 pages are in this category, out of 25 total.